Device with efficient photo-thermal conversion performance and application of device

A light-to-heat conversion and performance technology, applied in the directions of solar thermal energy, solar thermal power generation, solar thermal collectors, etc., can solve the problems of membrane pollution and the increase of spatial geometric size, so as to avoid precipitation pollution, efficient absorption and utilization, and maintain temperature. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

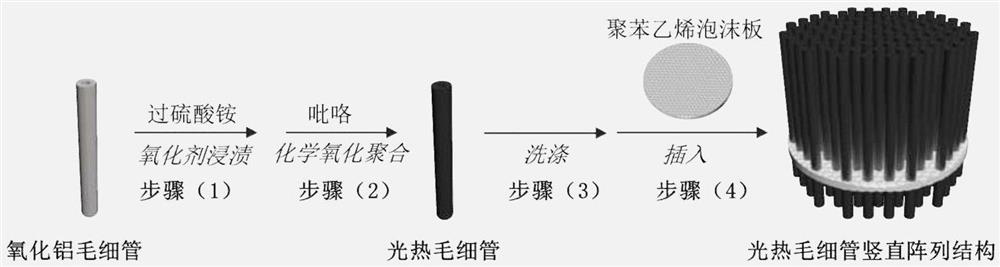

[0064] A method for preparing a device with high-efficiency light-to-heat conversion performance, consisting of figure 1 Shown:

[0065] 1) The preparation method of each photothermal capillary with high-efficiency photothermal conversion performance:

[0066] (1) Immerse each aluminum oxide capillary with an inner diameter of 1.0mm, a wall thickness of 0.65mm, and a length of 25mm to a concentration of 0.5molL -1 In the ammonium persulfate aqueous solution, let it stand at room temperature for 30 minutes, take it out, and blow dry at room temperature.

[0067] (2) Put 6 μL of pyrrole in a container, and seal the multiple aluminum oxide capillaries loaded with ammonium persulfate oxidant obtained by the method prepared in step (1) together in the container. Incubate at 50°C for 2 hours. The amount of pyrrole used is equivalent to 0.55 μL corresponding to the surface area of the hollow fiber base material per square centimeter.

[0068] (3) Wash the surface-modified alumi...

Embodiment 2

[0096] The difference from Example 1 is:

[0097] Replace the aluminum oxide capillary in step (1) with silicon oxide, porous ceramics, diatomaceous earth, or hydrophilic cellulose acetate, polycarbonate, polyamide, mixed cellulose ester, polyacrylonitrile, polyethylene film.

Embodiment 3

[0099] The difference from Example 1 is:

[0100] Replace the photothermal material in step (1) with carbon nanotubes, graphene, carbon quantum dots, activated carbon, ink or one or more mixed carbon materials, or spinel oxides formed of cobalt and other metals or a black dye of a mixture of several oxides.

[0101] The modification method was changed to physical deposition. Specifically: prepare N-methylpyrrolidone solution of carbon-containing material or aqueous solution / suspension of cobalt-containing black dye at a concentration of 0.1 wt%, block one end of the capillary, and deposit the photothermal material by vacuum filtration to the capillary surface, dried as Figure 11 visible.

[0102] Depend on Figure 11 It can be seen that the photothermal capillary with the photothermal layer of carbon nanotubes can be prepared by decompression and suction filtration. When pure water is dropped on the surface of the photothermal capillary, the water contact angle on the sur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com