Intelligent reversing control system, intelligent reversing control method, intelligent radiant tube heat regeneration device and intelligent radiant tube heat regeneration method

A control system and heat storage device technology, applied in the direction of combustion methods, lighting and heating equipment, gas fuel burners, etc., can solve the lack of heating power adjustment in the combustion process, over-temperature protection, inability to automatically realize temperature control and power adjustment, Problems such as the improvement of control technology for radiant tube combustion heat storage, etc., to facilitate the adjustment of workload, avoid high temperature damage, and prolong the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

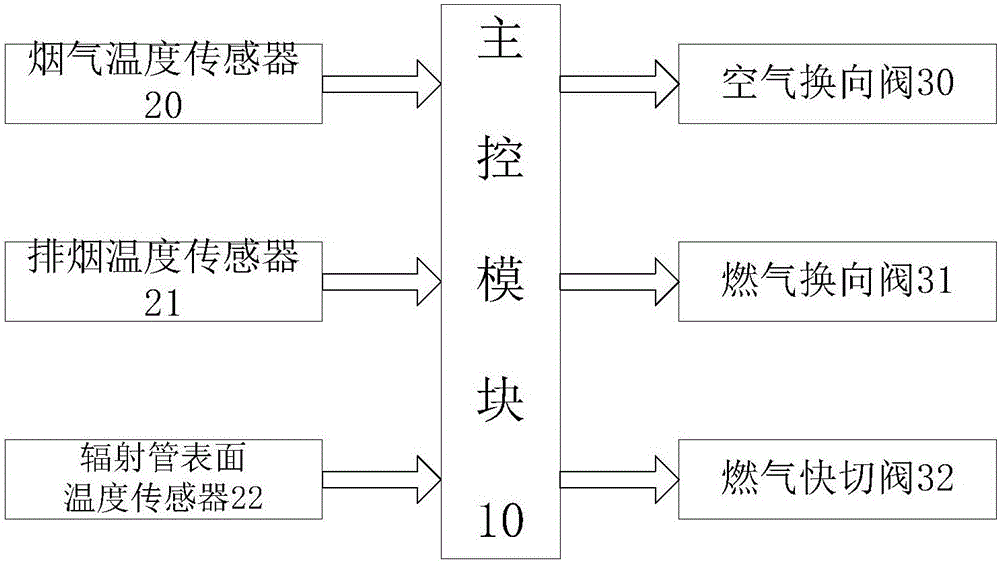

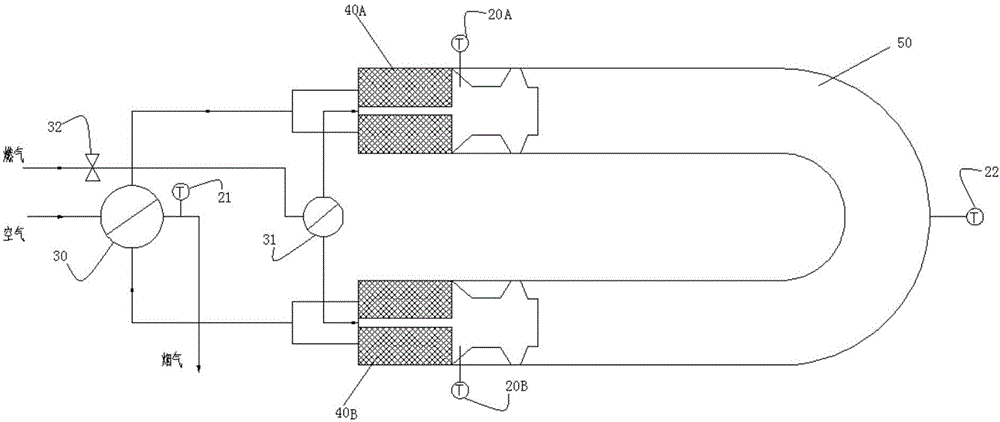

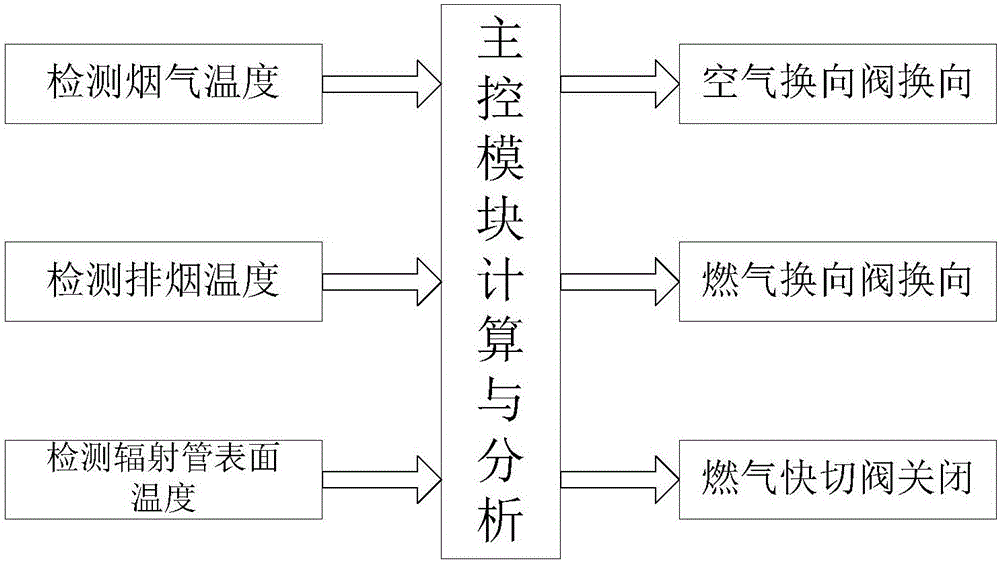

[0102] The intelligent commutation control system and the radiant tube intelligent heat storage device according to the present invention will be described in detail below with reference to specific embodiment 1.

[0103] The radiant tube intelligent heat storage device of the present invention includes a radiant tube, a gas channel, an air channel, a heat storage body A, a heat storage body B and an intelligent reversing control system, wherein the intelligent reversing control system includes a flue gas temperature sensor A. Flue gas temperature sensor B, exhaust gas temperature sensor, gas reversing valve, air reversing valve, main control module. In this embodiment, the radiant tube is made of steel U-shaped radiant tube. Of course, W or I-shaped radiant tube can also be used, which usually has two burners A and B; the regenerators A and B are ceramic honeycomb bodies, which are arranged in the U-shaped radiant tube. Both ends of the type radiant tube, that is, the regener...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com