Wave-optical comprehensive test instrument equipment

A comprehensive testing and wave optics technology, applied in the direction of instruments, optical devices, measuring devices, etc., can solve the problem of inability to measure the width of the central bright fringe of single-slit diffraction, the inability to measure the width of double-slit interference, the inability to measure the diameter of Airy disk, etc. problems, to achieve the effect of saving experimental costs, eliminating eccentricity, and long life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

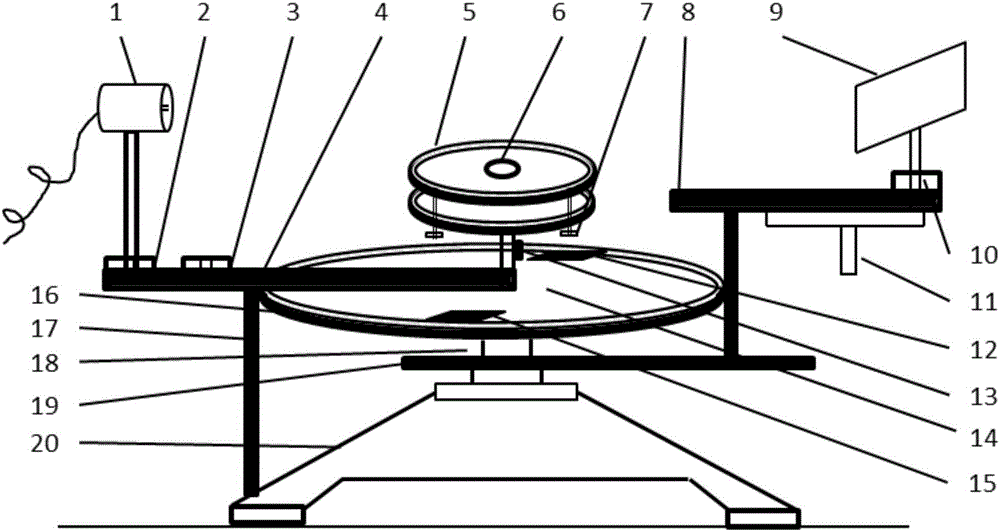

[0029] Embodiment 1-double slit interference experiment and the measurement of interference fringes:

[0030] Install and fix the prepared double slits (the distance between the double slits can be 0.1mm-0.5mm) on a bracket, insert the bracket into the spare base 3, turn on the laser 1, let the laser pass through the double slits, adjust the light screen 9, The light passing through the double slits is projected onto the light screen 9 to form interference fringes at equal intervals. Fine-tune the light screen 9 so that the center of one of the interference fringes (dark) fringes coincides with the white vertical line in the light screen, and record the readings of α cursor 15 and β cursor 12 as α 1 and beta 1 , and then move the handle 11 so that when the white vertical line reaches the center of the adjacent bright (dark) stripe, record the readings α of the two verniers at this time 2 and beta 2 , so that the moving angle θ of the light screen 9 of the hand wheel can be ...

Embodiment 2

[0031] Embodiment 2-Single slit diffraction experiment and measurement of central bright pattern

[0032] Fix the prepared single slit (the width of the single slit is 0.1mm-0.3mm) on a bracket, insert the bracket into the spare base 3, turn on the laser 1, let the laser pass through the single slit, and adjust the light screen 9 so that The diffraction pattern is projected onto the light screen 9, and the light screen 9 is moved so that the crosshairs are fixed at the center of the +1-level dark fringe, and the readings of the two cursors α cursor 15 and β cursor 12 are read as α 1 and beta 1 , and then turn the light screen so that the intersection of the cross on the light screen is fixed at the center of the -1 level dark fringe, and the readings of α cursor 15 and β cursor 12 at this time are denoted as α 2 and beta 2 , using the formula Calculate the rotated angle θ, and the distance L between the light screen and the single slit can be read from the light source tra...

Embodiment 3

[0033] Embodiment 3-circle hole diffraction experiment and the measurement of Airy disk diameter

[0034] Install the prepared round hole (the diameter of the round hole is 0.1mm—0.5mm) on the bracket, insert the bracket into the spare base 3, let the light emitted by the laser 1 pass through the round hole, and adjust the light screen 9 so that it passes through the round hole The light is projected onto the light screen, forming a circular hole diffraction pattern. Fine-tune the light screen 9 so that the left edge of the Airy disk (that is, the center of the first-level dark ring stripe) coincides with the intersection of the crosshairs on the light screen, and record the readings of the two cursors α cursor 15 and β cursor 12 at this time denoted as α 1 and beta 1 , and then move the handle so that the intersection of the crosshairs on the light screen falls in the center of the right edge of the Airy disk (the center of the first-level dark ring stripe), record the read...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com