Small-punch and continuous indentation integrated tester system

An indentation test and testing machine technology, which is applied in the field of testing machines, can solve the problems of slow application process of small punch test technology and continuous indentation test technology, inability to compare and analyze data horizontally, and great influence on the accuracy of results, etc. , to achieve the effect of promoting industrial application process, occupying small space and compact machine structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

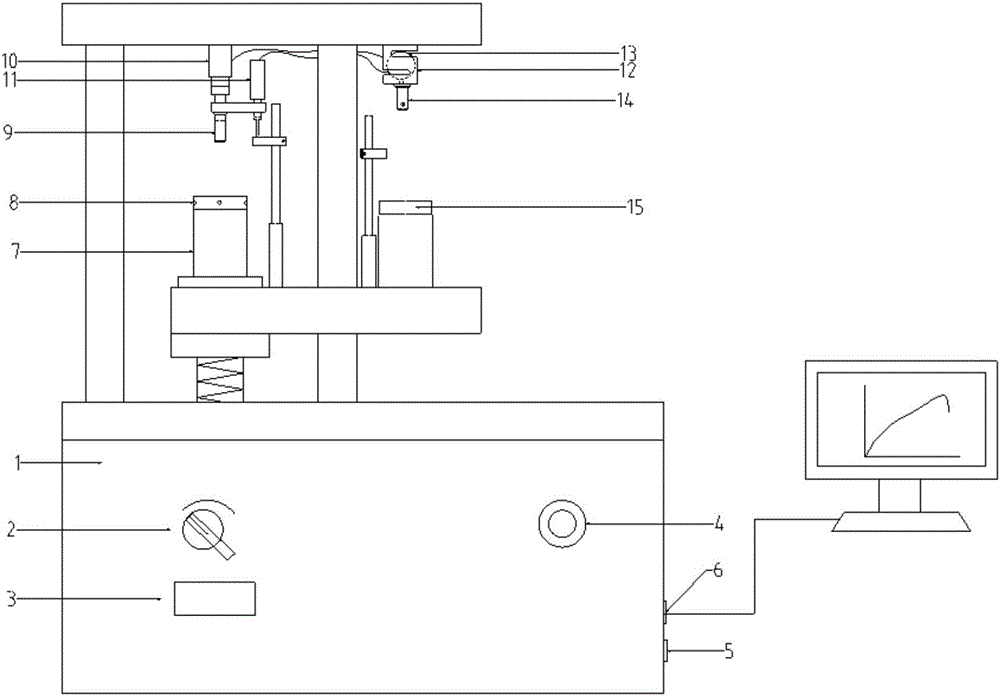

[0036] See figure 1 The present invention discloses a small plunger continuous indentation integrated testing machine system. The integrated testing machine system includes: a computer control system, a small plunger testing system, and a continuous indentation testing system. It consists of a control system and a servo motor. Control two test benches, save the test procedures of multiple tests through programming or adjusting parameters;

[0037] The computer control system includes the main body of the test machine. The main body of the test machine is provided with a switch knob of the test machine, an emergency stop button, and a control panel of the test machine that controls the up and down movement and speed of the test bed. All three parts are located The front side of the main body of the test machine is convenient for operation and control of the test machine; the main body of the test machine also includes a sensor interface and a computer interface. The sensor interfa...

Embodiment 2

[0047] A small plunger continuous indentation integrated testing machine system. The integrated testing machine system includes: a computer control system, a small plunger test system, and a continuous indentation test system. The computer control system is connected to the small plunger test system, Continuous indentation test system;

[0048] The small punch test system includes a first support table, a clamp, a centering module, a pressure rod, a first extensometer, a small punch test bench load cell, and a small punch test bench extensometer; the clamp is used to fix the test Sample and pressure rod; the pressure rod is connected with the load cell of the small punch test bench, and is used to apply load to the sample;

[0049] The continuous indentation test system includes a second support table, a continuous indentation indenter clamping rod, a continuous indentation test bench load sensor, and a continuous indentation test bench extensometer; the continuous indentation inde...

Embodiment 3

[0051] Such as figure 1 As shown, the small punch-continuous indentation integrated testing machine system of the present invention includes a computer control system, a small punch test system and a continuous indentation test system. The main box (1) of the testing machine is provided with a testing machine switch knob (2), an emergency stop button (4), and a testing machine control panel (3) that controls the up and down movement and speed of the test bench. All three parts are located The front side of the main body of the testing machine is easy to operate and control the testing machine. The support tables (7) and (15) are made of cylindrical steel ingots with large rigidity. For the small punch test bench, a centering module (8) is placed on the support table, and the small punch clamp can be adjusted by the adjustment screw on the edge of the module The alignment with the pressure rod, the inner diameter is φ45.5mm, the small punch clamp is placed in the module, and th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com