Electrolytic extraction and determination method for nonmetallic inclusions in steel

A non-metallic inclusion and determination method technology, applied in the field of metal electrochemistry, can solve the problems of many side reactions, complex formula, unsuitable for long-term use, etc., to achieve simplified extraction and separation process, clear electrolytic reaction, non-toxic and environmentally friendly formula Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] Below in conjunction with embodiment the present invention is described in further detail.

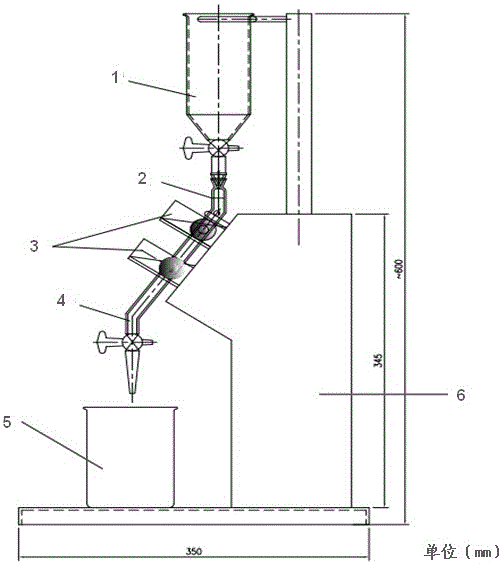

[0040] The electrolytic extraction and determination method of non-metallic inclusions in steel of the present invention, the process steps are as follows:

[0041] 1. Preparation of electrolyte

[0042] To prepare an inorganic electrolytic solution, take 1000mL of deionized water, 50g of potassium chloride, and 10g of citric acid monohydrate, mix and stir until completely dissolved, filter and place in a clean reagent bottle.

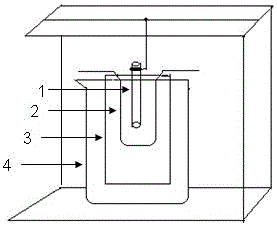

[0043] 2. Preparation of semi-permeable membrane

[0044] Dissolve 45g of cellulose acetate in 500mL of acetone, mix well and use the capsule cup and capsule ring as a mold to prepare a semi-permeable membrane cup.

[0045] 3. Preparation of samples

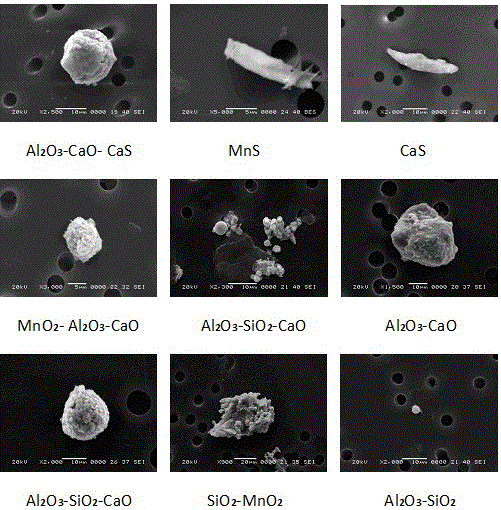

[0046] Take the sample to be electrolyzed and heat it to 840°C for solid solution strengthening treatment, then use sandpaper to remove the surface oxide skin and ultrasonically clean it for 5 minutes be...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Membrane pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com