A system for evaluating the environmental stress resistance performance of polyethylene resin and its application

A technology that is resistant to environmental stress and polyethylene resin, applied in the direction of material inspection products, etc., can solve the problems of long test period, inability to complete the test, hazards, etc., and achieve the effect of shortening the test period, long test period, and shortening the test period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

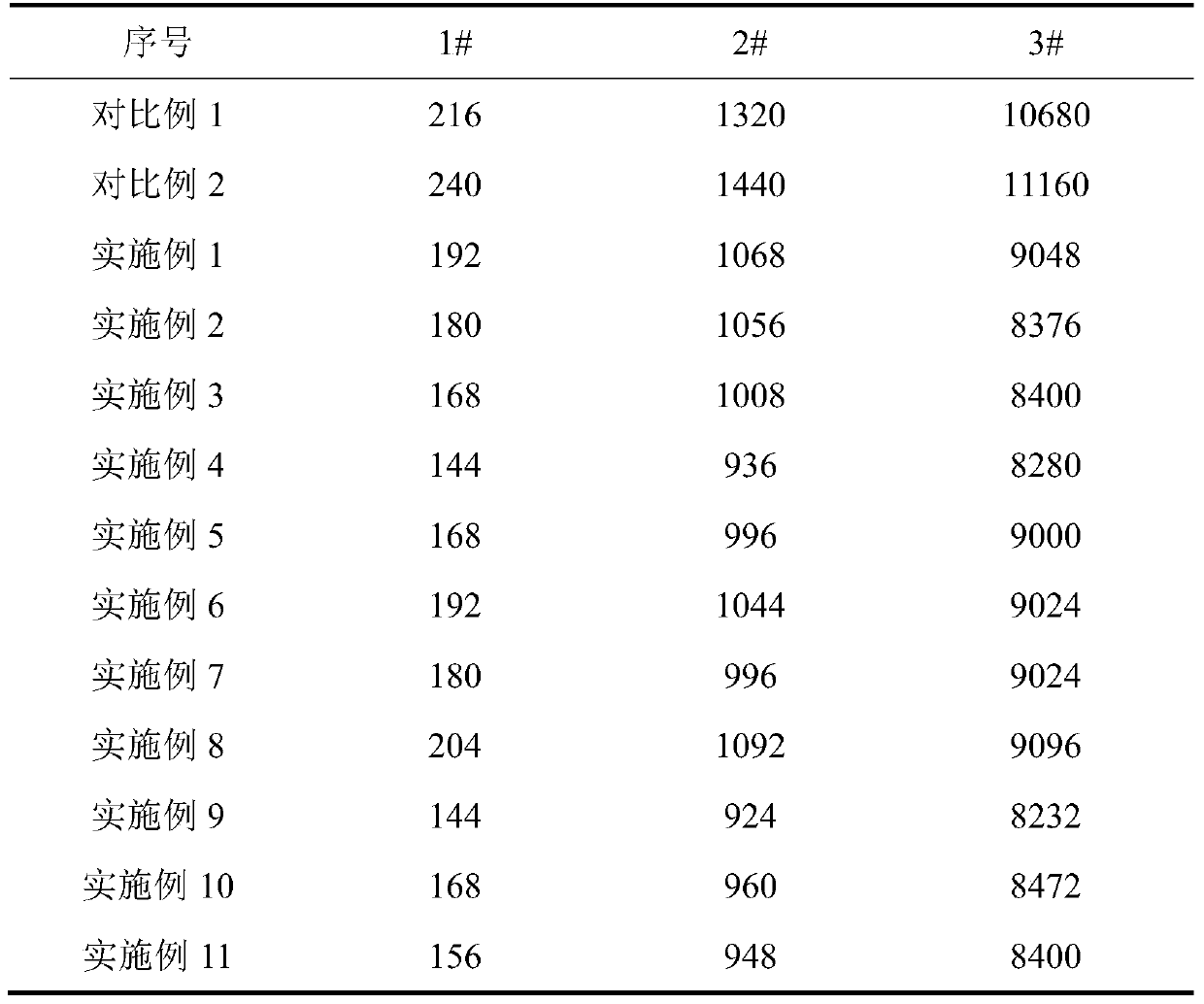

Embodiment 1

[0027] Use pareth-3, wherein the number of carbon atoms of the alkane chain segment is 11, and sodium lauryl sulfate forms a compound system, and the mass fraction ratio of pareth-3 and sodium lauryl sulfate is 100:0.01, the concentration of the aqueous solution is 10%. The ESCR test was carried out on the sample sample using the compound surfactant.

Embodiment 2

[0029] Use pareth-3, wherein the number of carbon atoms of the alkane chain segment is 13, and sodium lauryl sulfate forms a complex system, and the mass fraction ratio of pareth-3 and sodium lauryl sulfate is 100:0.01, the concentration mass ratio of the aqueous solution is 5%. The ESCR test was carried out on the sample sample using the compound surfactant.

Embodiment 3

[0031] Use pareth-3, wherein the number of carbon atoms of the alkane chain segment is 11, and sodium lauryl sulfate forms a compound system, and the mass fraction ratio of pareth-3 and sodium lauryl sulfate is 100:0.01, the concentration of the aqueous solution is 0.5%. The ESCR test was carried out on the sample sample using the compound surfactant.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com