Three-dimensional electrode material, preparation method therefor, and solid super-capacitor

A technology for supercapacitors and three-dimensional electrodes, applied in the manufacture of hybrid/electric double layer capacitors, hybrid capacitor electrodes, etc., can solve the problem of small contact area of active materials, improve area specific capacitance, improve conductivity, and increase contact area Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] This embodiment firstly provides a kind of three-dimensional electrode material, and it mainly comprises: the Al nano nail array formed on the aluminum foil; The nickel layer formed on the Al nano nail array; The MnO formed on the nickel layer x Nanopin arrays. Further, the thickness of the nickel layer is 100-500 nm. Among them, MnO x Refers to manganese oxide, generally speaking, x=1~2, such as manganese oxide (MnO), manganese dioxide (MnO 2 ), manganese trioxide (Mn 2 o 3 ) etc., it can be a kind of manganese oxide, also can be to contain more than two kinds of manganese oxides, for example can be to contain MnO and MnO at the same time 2 . In this example, MnO x Is the choice of MnO 2 A detailed description will be given as a specific example.

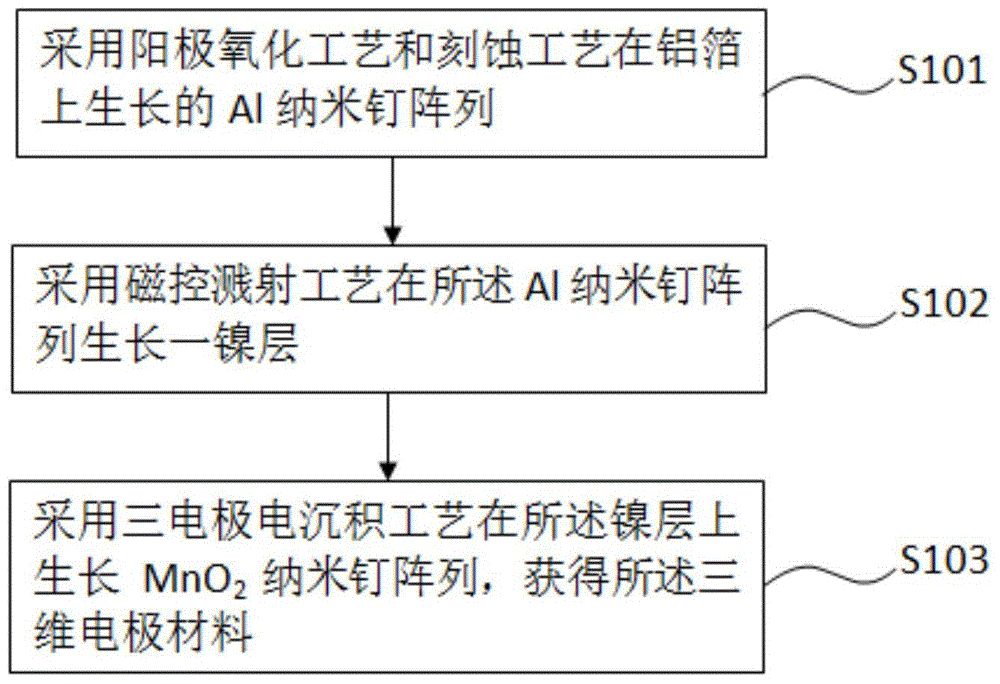

[0033] like figure 1 As shown, the preparation method of the above-mentioned three-dimensional electrode material comprises steps:

[0034]S101, an Al nanonail array grown on an aluminum foil by using an anodic oxi...

Embodiment 2

[0041] This embodiment provides a solid supercapacitor. like Figure 4 Said, the capacitor comprises a gold-sprayed polyethylene terephthalate film 1, a first electrode 2, a second electrode 3, a first electrode 2 and a gold-sprayed polyethylene terephthalate film which are sequentially stacked. Glycol ester film 1. Wherein, the first electrode is an electrode prepared from the three-dimensional electrode material provided in Example 1, the second electrode is a CCG (chemical convert graphene, chemically converted graphene) electrode, and the first electrode and the second electrode are A gel electrolyte is attached to the electrodes.

[0042] Wherein, the preparation of the first electrode 2 refers to the method provided in Example 1.

[0043] The preparation of the second electrode 3 specifically includes: 100-110 mL of GO (graphite oxide, graphite oxide) solution with a concentration of 0.5 mg / mL, 0.2-0.5 mL of hydrazine hydrate with a concentration of 35 wt % and 0.35-0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com