Organic photoelectric device and preparation method thereof and composition with hole transport performance

A technology of photoelectric devices and hole transport layers, which is applied in the manufacture of organic semiconductor devices, electrical solid devices, semiconductor/solid devices, etc., can solve the problems of reduced carrier transport performance, limited large-scale applications, and poor contact performance. Achieve the effect of improving interface contact performance, increasing interface charge transfer efficiency, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

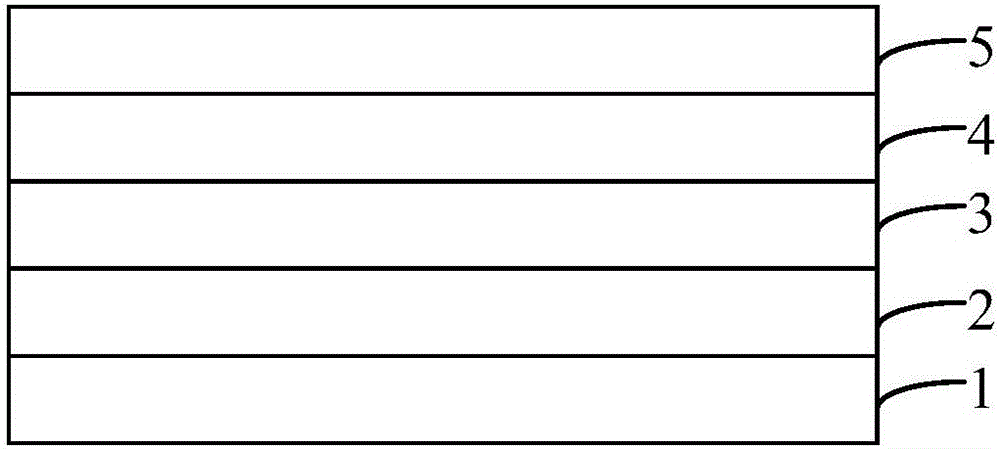

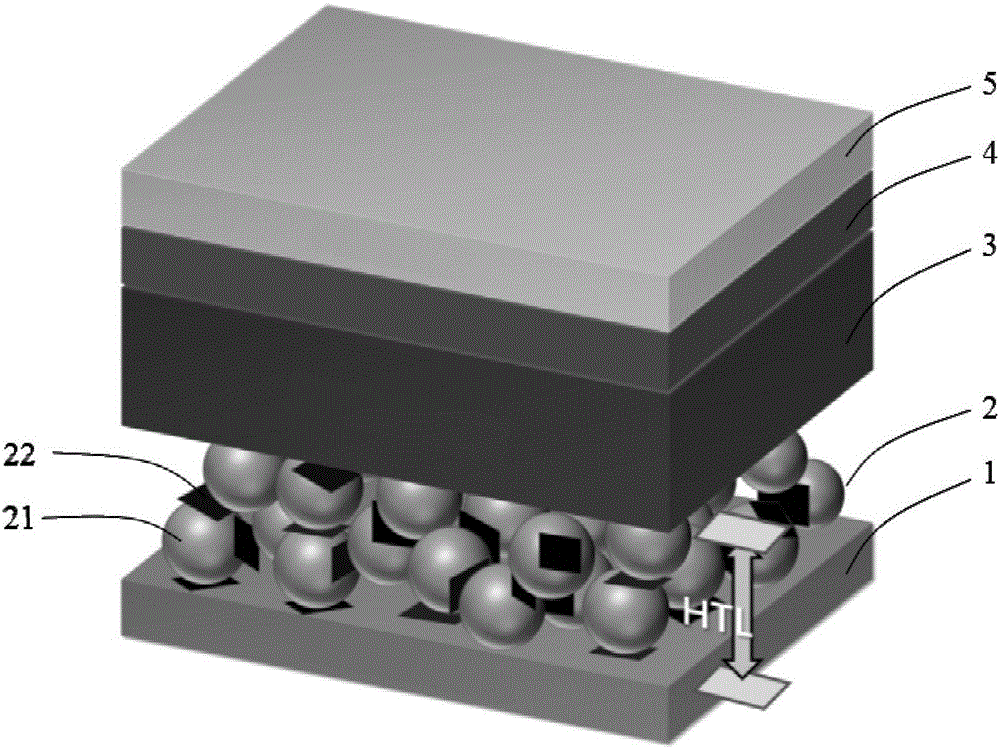

[0052] In a second aspect, an embodiment of the present invention provides a method for preparing an organic photoelectric device, including:

[0053] provide the anode;

[0054] Prepare a hole transport layer on the anode by coating or printing, then prepare a functional layer on the hole transport layer, and prepare a cathode on the functional layer to obtain an organic photoelectric device, or

[0055] provide the cathode;

[0056] Prepare a functional layer on the cathode, and then prepare a hole transport layer on the functional layer by coating or printing, and prepare an anode on the hole transport layer to obtain an organic photoelectric device;

[0057] The functional layer includes a photoelectric active layer or a light-emitting layer, the material of the hole transport layer includes black phosphorus, the number of layers of the black phosphorus is single layer or multiple layers, and the lateral size of the black phosphorus is 1nm-100μm.

[0058] In one embodime...

Embodiment 1

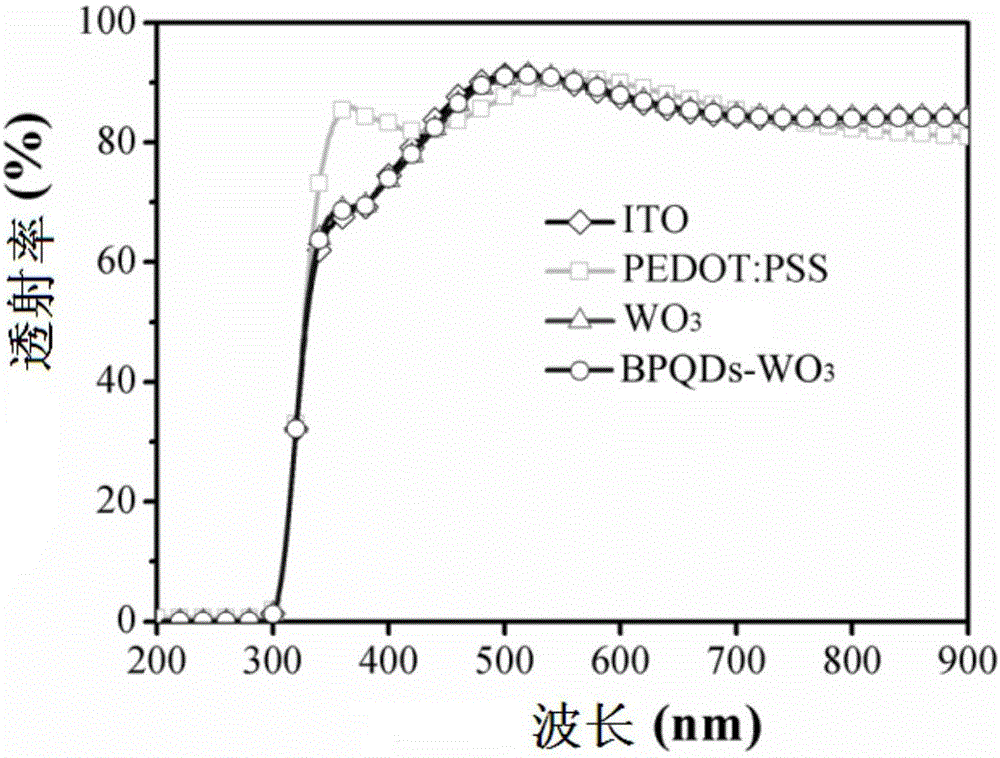

[0105] A method for preparing a composition with hole transport properties, comprising:

[0106] (1) Nanoscale WO 3 Place in isopropanol and centrifuge at 1000 rpm for 4 minutes to remove large particles and take the supernatant to obtain nanoscale WO 3 solution;

[0107] Grind black phosphorus (BP) crystals into powder, add NMP and NaOH, stir vigorously at 10°C for 1 hour, centrifuge at 100rpm for 5 minutes, take the supernatant to obtain a solution containing black phosphorus; the number of layers of black phosphorus is about 20, The lateral dimension of black phosphorus is 100 μm;

[0108] (2) Nanoscale WO 3 The solution is mixed with a solution containing black phosphorus to obtain a mixed solution, and in the mixed solution, nanoscale WO 3 The mass ratio to black phosphorus is 95:5, and the mixed solution is dried to obtain a composition with hole transport properties. Compositions with hole transport properties include black phosphorus and nanoscale WO 3 Particles,...

Embodiment 2

[0110] A method for preparing a composition with hole transport properties, comprising:

[0111] (1) Nanoscale MoO 3 Place in ethanol and centrifuge at 1000 rpm for 4 minutes to remove large particles and take the supernatant to obtain nano-sized MoO 3 solution;

[0112] Grind black phosphorus (BP) crystals into powder, add NMP and NaOH, stir vigorously at 50°C for 10 hours, centrifuge at 7000rpm for 20 minutes, take the supernatant to obtain a solution containing black phosphorus; the number of layers of black phosphorus is about 10 , the lateral dimension of black phosphorus is 10 μm;

[0113] (2) Nanoscale MoO 3 The solution is mixed with a solution containing black phosphorus to obtain a mixed solution, and in the mixed solution, nanoscale MoO 3 The mass ratio to black phosphorus is 90:10, the mixed solution is ultrasonically reacted at 70° C. for 40 min, and the obtained product is dried to obtain a composition with hole transport properties. Compositions with hole-t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Horizontal size | aaaaa | aaaaa |

| Horizontal size | aaaaa | aaaaa |

| Horizontal size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com