Electrode material and preparation method and application thereof

A technology of organic electrodes and organic negative electrodes, applied in battery electrodes, circuits, electrical components, etc., can solve problems such as poor cycle stability and low specific capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

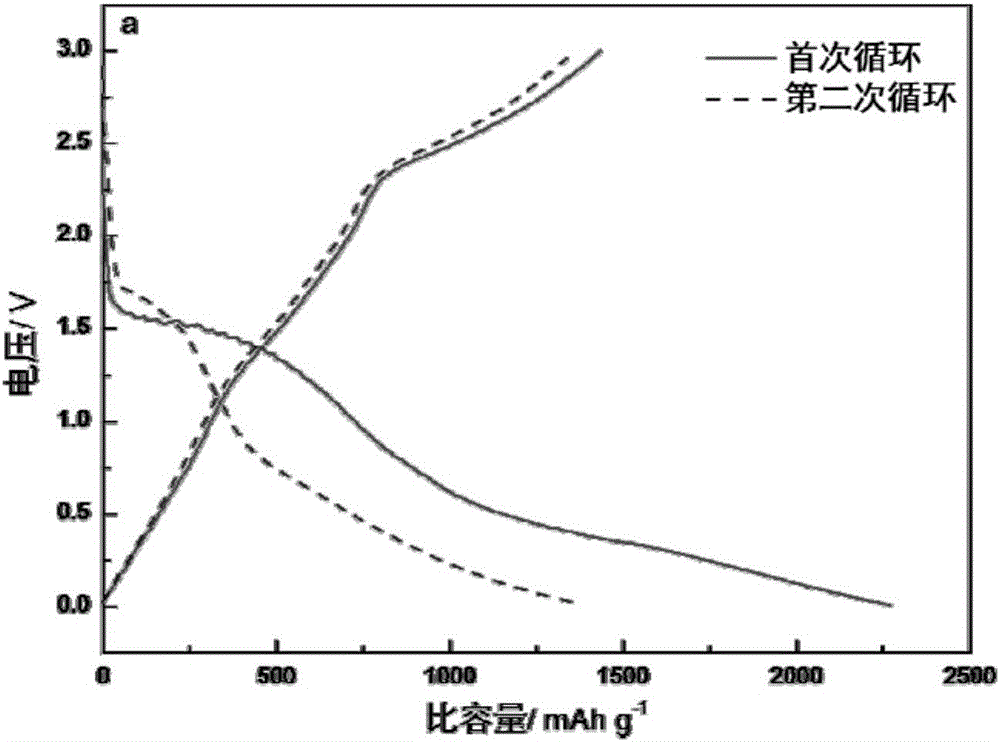

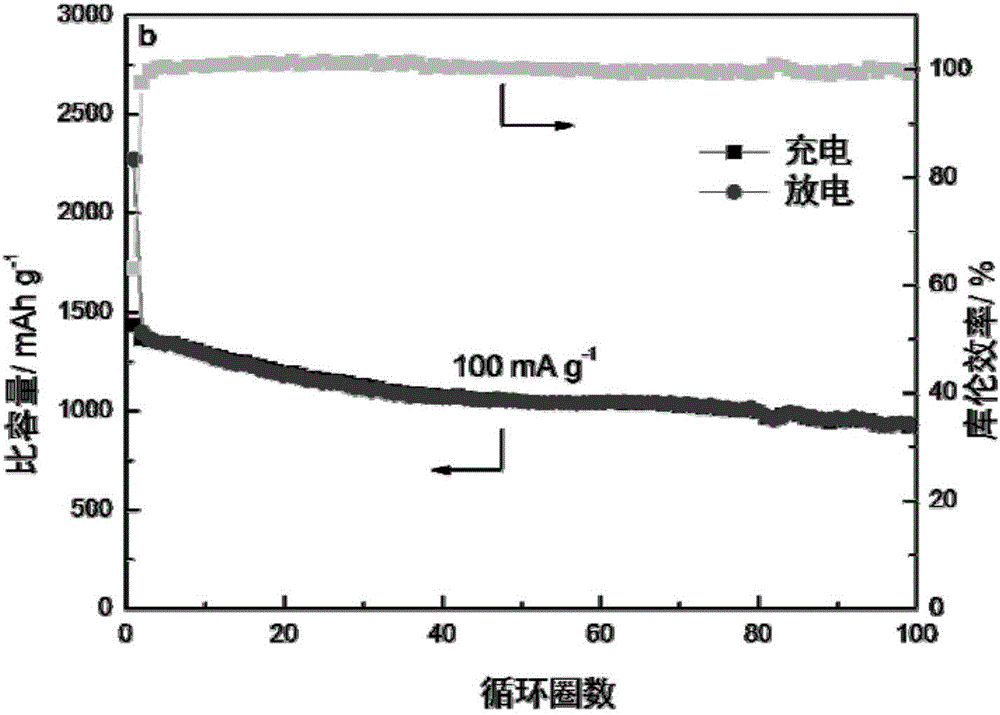

Examples

Embodiment 1

[0061] C 6 h 6 o 9 S 2 Preparation of:

[0062] Weigh 60 mmol of 1,2,3-trihydroxybenzene, pour it into a reaction flask, and add 200 mL of concentrated sulfuric acid to obtain a white solid. Stir at room temperature for 48h to fully react. filtered and dried to obtain C 6 h 6 o 9 S 2 White powder.

[0063] C 6 h 6 o 9 S 2 Preparation of negative electrode sheet:

[0064] with C 6 h 6 o 9 S 2 As an organic anode material, weigh 120 mg of C 6 h 6 o 9 S 2Put the powder into an agate mortar, grind for 5 minutes, weigh 60 mg of conductive additive such as acetylene black, put it into the agate mortar, continue grinding for 5 minutes, and then add 5 mL of N-methylpyrrolidone solution dissolved with PVDF binder (solution concentration 15mg / mL), continue to grind for 40min, and then apply on copper foil to prepare C 6 h 6 o 9 S 2 Negative plate.

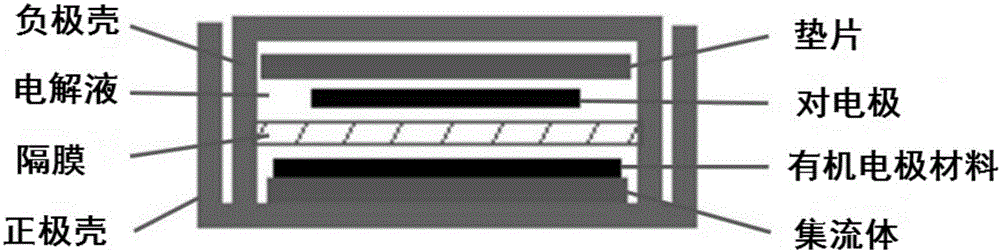

[0065] Assembly of Li-ion half-cells:

[0066] will prepare C 6 h 6 o 9 S 2 Negative electrodes were assemb...

Embodiment 2

[0078] C 6 h 4 o 9 S 2 Li 2 Preparation of:

[0079] Weigh the synthetic C of 10mmol embodiment one 6 h 6 o 9 S 2 , add 5mL of distilled water, stir at room temperature for 2min to dissolve, continue to add 20mL of saturated lithium chloride solution, stir for 5min, a white solid appears, continue to stir for 12h, make it react fully, filter, dry, and obtain C 6 h 4 o 9 S 2 Li 2 .

[0080] C 6 h 4 o 9 S 2 Li 2 Preparation of negative electrode sheet:

[0081] with C 6 h 4 o 9 S 2 Li 2 As an organic anode material, weigh 120 mg of C 6 h 4 o 9 S 2 Li 2 Put the powder into an agate mortar, grind for 5 minutes, weigh 60 mg of conductive additive such as acetylene black, put it into the agate mortar, continue grinding for 5 minutes, and then add 5 mL of N-methylpyrrolidone solution dissolved with PVDF binder (solution concentration 15mg / mL), continue to grind for 40min, and then apply on copper foil to prepare C 6 h 4 o 9 S 2 Li 2 Negative plate. ...

Embodiment 3

[0089] C6 h 4 o 9 S 2 Na 2 Preparation of:

[0090] Weigh the synthetic C of 10mmol embodiment one 6 h 6 o 9 S 2 , add 5mL of distilled water, stir at room temperature for 2min to dissolve, continue to add 20mL of saturated sodium chloride solution, stir for 5min, a white solid appears, continue to stir for 12h, make it react fully, filter, dry, and obtain C 6 h 4 o 9 S 2 Na 2 .

[0091] C 6 h 4 o 9 S 2 Na 2 Preparation of negative electrode sheet:

[0092] with C 6 h 4 o 9 S 2 Na 2 As an organic anode material, weigh 120 mg of C 6 h 4 o 9 S 2 Na 2 Put the powder into an agate mortar, grind for 5 minutes, weigh 60 mg of conductive additive such as acetylene black, put it into the agate mortar, continue grinding for 5 minutes, and then add 5 mL of N-methylpyrrolidone solution dissolved with PVDF binder (solution concentration was 15mg / mL), continued to grind for 40 minutes, and then coated on copper foil to prepare C 6 h 4 o 9 S 2 Na 2 Negative ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Discharge capacity | aaaaa | aaaaa |

| Charging capacity | aaaaa | aaaaa |

| Capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com