Preparation method of laminar composite for negative electrode of secondary metal lithium battery

A battery negative electrode and compound technology, which is applied in the direction of electrode manufacturing, battery electrodes, lithium storage batteries, etc., can solve the problem of weak bonding, and achieve the effects of small overpotential, convenient operation, and long cycle life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

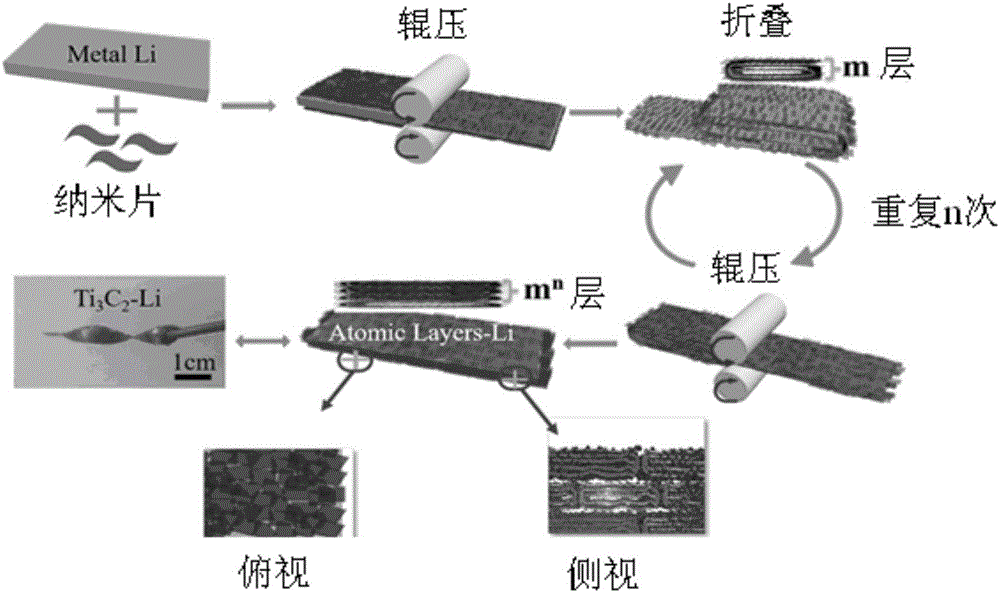

[0037] Operation process such as figure 1 ,

[0038] A kind of Ti 3 C 2 -Li sheet-like composite, which is prepared by the following steps:

[0039] Take a lithium sheet and Ti with a mass ratio of 9:1 3 C 2 Nanosheet powder, in which the thickness of the lithium sheet is 1mm and the area is 4cm 2 , Ti 3 C 2 The thickness of the nanosheet is 5nm, the Ti 3 C 2 Spread the nanosheet powder evenly on the surface of the elemental lithium with a medicine spoon, push it horizontally into the pair of rollers with a gap of 0.5mm, and perform rolling to make the Ti 3 C 2 Nanosheet powder enters lithium metal, Ti after rolling 3 C 2 - The area of the lithium complex is twice the area of the original lithium sheet.

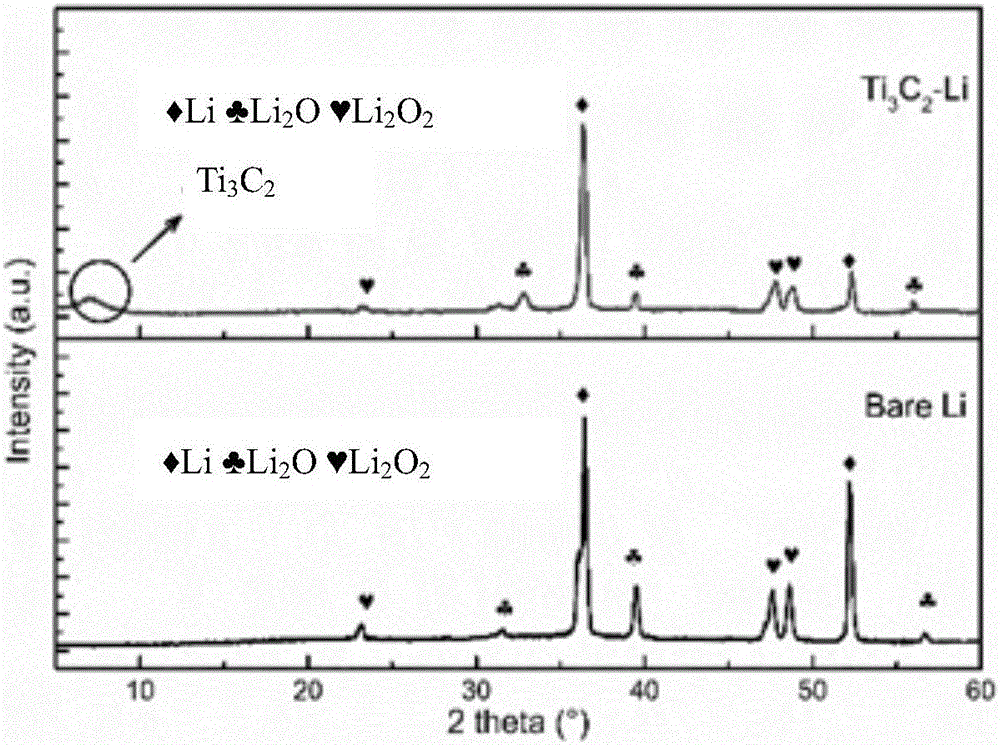

[0040] the Ti 3 C 2 -Li composite sheet is folded in half and rolled again, keeping the Ti 3 C 2 - Li has an area of 4cm 2 . The folding and rolling steps were repeated 10 times to finally obtain the layered Ti 3 C 2 - Li composite sheet, punching t...

Embodiment 2

[0046] A kind of G-Li flake compound (G represents graphene), its preparation method is basically the same as embodiment 1, and difference is that Ti 3 C 2 Nanosheet powder is replaced by graphene powder. The graphene used therein is prepared by the method of ultrasonically exfoliating bulk graphite, and the thickness of the graphene sheet is 1 nm.

[0047] Characterize the electrochemical performance of the obtained G-Li flake composite, the results can be found in Figure 4 with Figure 5 . Symmetrical battery tests show that the G-Li composite electrode is at 1mA / cm 2 Charge-discharge cycle under current density, its overpotential showed a trend of decreasing first and then increasing. The initial overpotential was 106mV, and the overpotential increased by 114% after 200 cycles.

Embodiment 3

[0049] A Cu-Li flaky composite, the preparation method of which is basically the same as in Example 1. The difference is that the Ti 3 C 2 The nano-sheet powder is replaced by Cu nano-powder with a particle size of 100-200nm. The number of repetitions of folding rolling was six times.

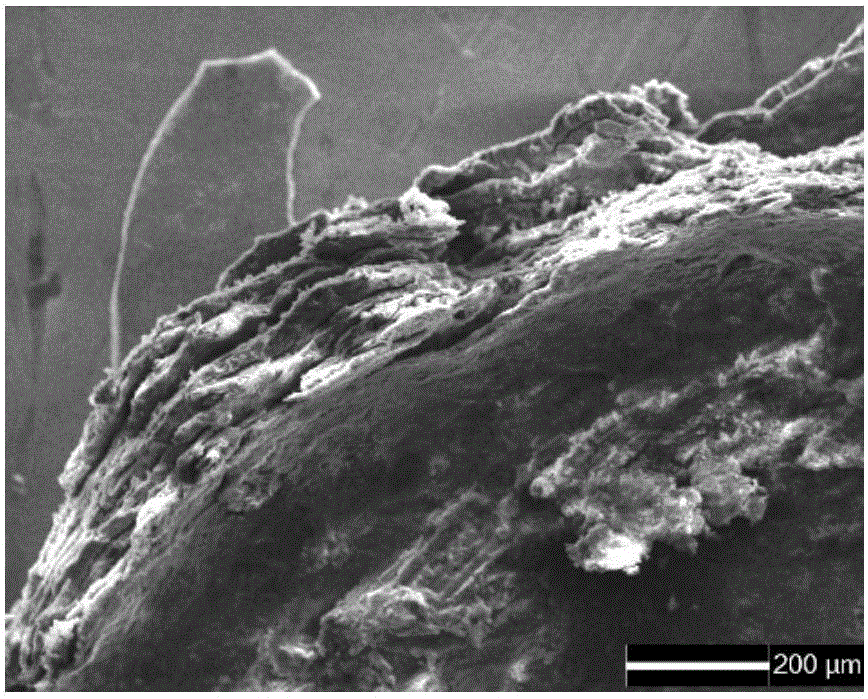

[0050] Characterize the morphology of the obtained Cu-Li flake composite, the results can be found in Figure 8 . with Ti 3 C 2 -Similar to Li, the composite exhibits a lamellar structure, but due to the different number of repetitions of folding and rolling, the corresponding sheet thickness is the same as that of Ti 3 C 2 - Li is different.

[0051] The electrochemical properties of the obtained Cu-Li flake composites were characterized. Figure 9 is the cycle performance graph of the layered Cu–Li symmetric battery. Symmetrical battery tests show that the Cu-Li composite electrode exhibits a more stable voltage distribution throughout the cycle than the pure Li electrode, at 1 mA / c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com