Lemon frozen sugar and production technology thereof

A production process, lemon technology, applied in the confectionary industry, confectionary, food science, etc., can solve the problems of unsatisfactory storage period of dried lemon slices, single acidity and flavor, etc., to increase edibility and interest, and unique flavor , smooth taste effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0056] Prepare food glue according to Table 1 to obtain food glue numbers A to F, see Table 1.

[0057] Table 1

[0058] No. Carrageenan / g Food gelatin / g Konjac gum / g Xanthan collagen / g Agar / g Gellan gum / g A 0.6 0.6 0.6 0.6 0.3 0.3 B 0.5 0.5 0.5 0.5 - - C 0.5 1.5 - - - - D 1.5 0.5 - - - - E 0.8 0.8 - - - - F 1.6 - - - -

Embodiment 2

[0060] To prepare lemon juice and lemon puree:

[0061]Take fresh lemons and clean them with clean water, use a dermabrasion machine to break the oil bubbles on the skin of the lemons, put them into a disinfectant solution, immerse them completely, and soak them for two days to obtain sterilized lemons; the disinfectant solution is sodium sulfite and lemon A mixed solution of acid, the lemon, the sodium sulfite in the disinfectant, the citric acid in the disinfectant and the water in the disinfectant have a mass ratio of 1:0.01:0.01:2.

[0062] Rinse the sterilized lemons with clear water to remove residual sulfur dioxide on the surface to obtain rinsed lemons; the rinsing time is 5-8 hours, and the clear water is replaced 2-3 times during the rinsing process.

[0063] The rinsed lemons are sliced, and the lemon seeds in the pulp are removed to obtain lemon slices.

[0064] After boiling the debittering solution, add the lemon slices and boil for 60s to 180s to obtain debitte...

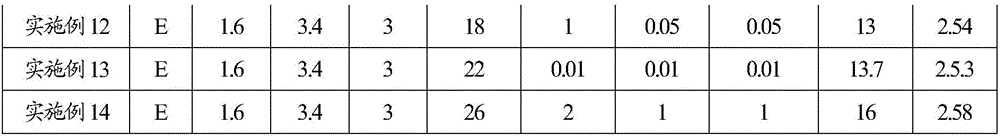

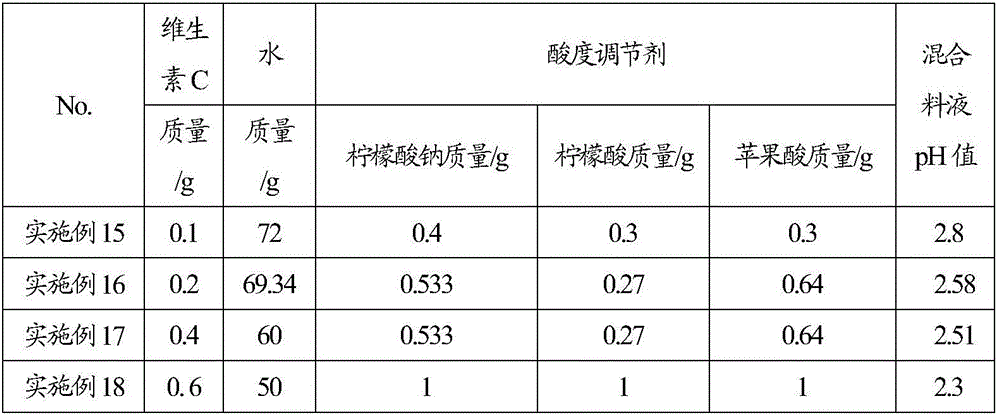

Embodiment 3~14

[0067] A production process of lemon jelly candy, comprising:

[0068] Mix food gum and sweetener according to Table 2, stir evenly, add 69.34g of water to dissolve, heat and stir until boiling, then boil on low heat, heat to boiling, then cool down to the blending temperature of 67-73°C, add sodium citrate 0.533 g, citric acid 0.27g, malic acid 0.64g, and add the lemon juice that embodiment 2 obtains according to table 2 and the lemon puree deployment and obtain the mixture liquid, measure the described mixture liquid sweetness that obtains, pH value, the results are shown in the table 2. Fill the mixed material liquid while it is hot to obtain a semi-finished product, control the filling time to 0.5-2 minutes, and the temperature of the material liquid during the filling process to be 67-73 °C. Carried out, the gelation speed is accelerated;

[0069] The semi-finished product is sterilized in a water bath at 88-92°C for 10 minutes, cooled at 23-27°C, and dehydrated on the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com