Process for preparing crystal whisker calcium carbonate through combined production of high-purity magnesium hydrate and by-product

A technology of magnesium hydroxide and calcium carbonate, applied in the directions of magnesium hydroxide, calcium carbonate/strontium/barium, calcium/strontium/barium compounds, etc., can solve the problem of uneven particle size, waste of resources, and by-product calcium chloride cannot be effectively obtained. It can achieve the effect of simple process and low production cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

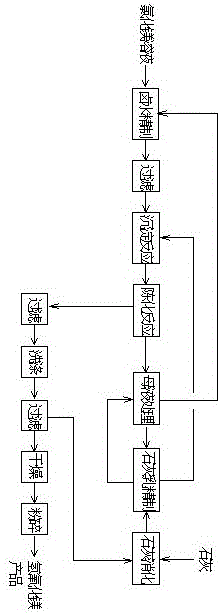

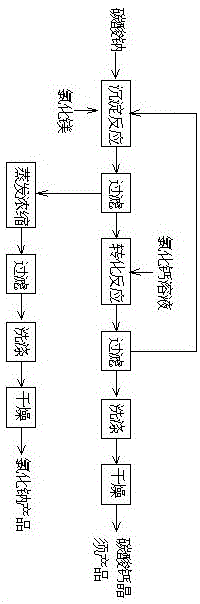

[0020] Combine now figure 1 , figure 2 The present invention is further described,

[0021] Preparation process of high-purity magnesium hydroxide

[0022] Include the following steps:

[0023] (1) Add the magnesium chloride-containing precipitate and flocculant collected in the mother liquor treatment tank after the production of potassium nitrate to the magnesium chloride solution, and filter after reacting for a period of time to obtain a refined magnesium chloride solution;

[0024] (2) Mix lime and water for lime digestion, and then add the obtained lime milk into the lime milk refining tank, and obtain refined lime milk after treatment;

[0025] (3) Add the refined magnesium chloride solution into the precipitation reaction tank, and at the same time add the refined lime solution for reaction to obtain magnesium hydroxide precipitation;

[0026] (4) Transfer the reaction solution containing magnesium hydroxide precipitation into an aging tank for aging reaction, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com