Preparation method for alpha-hydroxy cyclo-pentadecanone

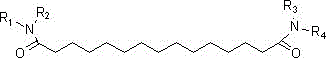

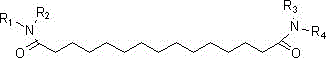

A kind of technology of cyclopentadecanone, alkyl pentadecanediamide

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Add 40mL of dry xylene to a 250mL dry four-neck flask equipped with a stirring, thermometer, condenser, and dropping funnel, add 1.60g (0.07mol) of sodium metal to the flask, and slowly raise the temperature to 2 Boil the toluene, stir rapidly for 5 minutes, and beat the sodium into silvery white fine particles. Control the temperature at 100°C, slowly add dropwise 40mL xylene solution dissolved with 3.82g (0.01mol) N,N,N',N'-tetraethylpentadecanediamide, after 4 hours of dropwise addition, keep warm React for 2 hours. After the reaction was completed, 8 mL of absolute ethanol was added dropwise to decompose the remaining metallic sodium. The insoluble matter was removed by filtration, the filtrate was washed with water until neutral, and the solvent was distilled off under reduced pressure to obtain 2.64 g of a crude product. The reaction product was analyzed by gas chromatography, and the content of α-hydroxycyclopentadecone was 90.8%.

Embodiment 2

[0027] Add 40ml of dry toluene to a 250ml dry four-neck flask equipped with stirring, thermometer, condenser and dropping funnel, add 1.60g (0.07mol) sodium metal to the flask, and slowly raise the temperature until the toluene boils under the protection of nitrogen , stirred rapidly for 5 minutes, and beat the sodium into silvery white fine particles. Control the temperature at 90°C, add dropwise 40ml of toluene solution dissolved with 4.38g (0.01mol) N,N,N',N'-tetrapropylpentadecanediamide, after 4 hours of dropwise addition, keep warm for 3 Hour. After the reaction was completed, 8 mL of absolute ethanol was added dropwise to decompose the remaining metallic sodium. The insoluble matter was removed by filtration, the filtrate was washed with water until neutral, and the solvent was distilled off under reduced pressure to obtain 2.68 g of a crude product. The reaction product was analyzed by gas chromatography, and the content of α-hydroxycyclopentadecone was 89.3%.

Embodiment 3

[0029] Add 40ml of dry benzene to a 250ml dry four-neck flask equipped with stirring, thermometer, condenser and dropping funnel, add 2.30g (0.10mol) sodium metal to the flask, and slowly raise the temperature until the benzene boils under the protection of nitrogen , stirred rapidly for 5 minutes, and beat the sodium into silvery white fine particles. Control the temperature at 80°C, add dropwise 40ml of benzene solution in which 4.94g (0.01mol) N,N,N',N'-tetrabutylpentadecanediamide is dissolved, and after 5 hours of dropwise addition, keep warm for 5 Hour. After the reaction was completed, 8 mL of absolute ethanol was added dropwise to decompose the remaining metallic sodium. The insoluble matter was removed by filtration, the filtrate was washed with water until neutral, and the solvent was distilled off under reduced pressure to obtain 2.70 g of a crude product. The reaction product was analyzed by gas chromatography, and the content of α-hydroxycyclopentadecone was 88....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com