Metallized film capacitor encapsulation wax

A metallized film and capacitor technology, applied in the field of capacitor potting, can solve the problems of ductility and plasticity, easy to be brittle, easy to leak, large shrinkage, etc., to achieve the effect of improving ductility and plasticity, improving high temperature resistance, and increasing service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

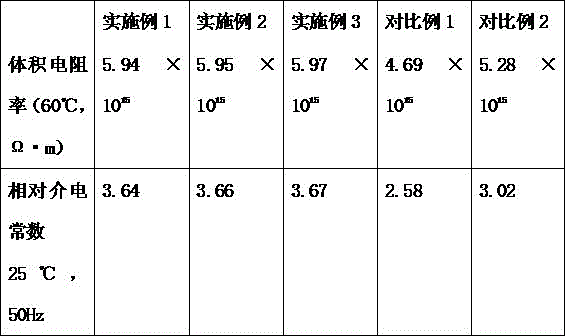

Examples

Embodiment 1

[0013] A metallized film capacitor potting wax, which is made of the following components in parts by weight: modified petroleum wax 80, nanometer zinc oxide 2, polychlorotrifluoroethylene 10, polyvinyl alcohol 8, and coconut acid monoethanolamide 23 , rosin 2, methyl cellulose 4, mica powder 12, medical stone powder 12.

Embodiment 2

[0015] A metallized film capacitor potting wax, made of the following components in parts by weight: modified petroleum wax 100, nano-zinc oxide 4, polychlorotrifluoroethylene 16, polyvinyl alcohol 10, coconut oil monoethanolamide 25 , rosin 5, methyl cellulose 7, mica powder 14, medical stone powder 14.

Embodiment 3

[0017] A metallized film capacitor potting wax, made of the following components in parts by weight: modified petroleum wax 90, nano-zinc oxide 3, polychlorotrifluoroethylene 14, polyvinyl alcohol 9, coconut acid monoethanolamide 24 , Rosin 3, methyl cellulose 5, mica powder 13, medical stone powder 13.

[0018] In the above-mentioned embodiment:

[0019] The modified petroleum wax is made of the following components in parts by weight: petroleum wax 40, polyethylene wax 2, maleic acid 0.4, and its preparation method is: adding polyethylene wax and petroleum wax to the reactor and heating To melting, add maleic acid slowly, stir while heating, until mixing evenly, start compressor, feed oxygen in the reactor, after 3 hours, close compressor, stop feeding of oxygen, from reactor The reactant is taken out from the medium and dried to obtain the desired modified petroleum wax.

[0020] The particle size of the nano zinc oxide is 28nm.

[0021] The particle size of the mica pow...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com