Tert-vinegar emulsion expansion-type fireproof paint and preparation technology thereof

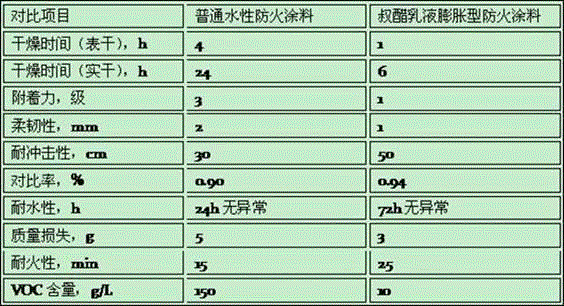

A technology of tertiary vinegar emulsion and fireproof coating, which is applied in fireproof coatings, coatings, etc., can solve problems such as resource waste, solvent environmental pollution, and human hazards, and achieve the effects of strong coating adhesion, pollution reduction, and good adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

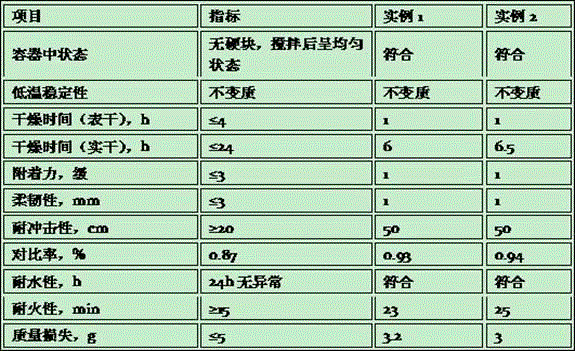

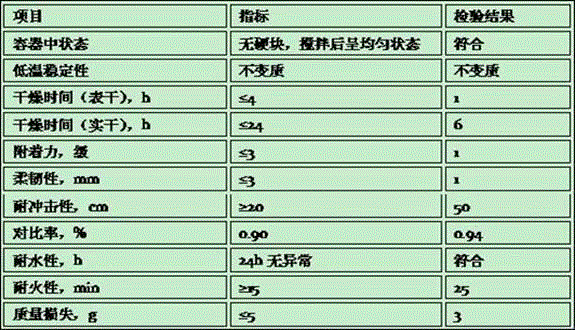

Embodiment 1

[0020] Example 1: A kind of tertiary vinegar emulsion intumescent fireproof coating and its preparation process involved in the present invention, formulated according to its mass fraction ratio: 35 parts of deionized water, 0.1 part of alkaloid, 0.3 part of RS610 wetting and dispersing agent , 0.2 parts of hydroxyethyl cellulose, 0.3 parts of DF681F defoamer, 0.2 parts of RS preservative, 0.2 parts of AN130 PH regulator, 0.2 parts of A401 alkali swelling thickener, 2 parts of film-forming aids, 10 parts of melamine MEL, Pentaerythritol PER 12 parts, ammonium polyphosphate APP 20 parts, titanium dioxide 4 parts, tertiary vinegar emulsion 15 parts.

Embodiment 2

[0021] Example 2: A kind of tertiary vinegar emulsion intumescent fireproof coating and its preparation process involved in the present invention, formulated according to its mass fraction ratio: 30 parts of deionized water, 0.1 part of alkaloid, 0.4 part of RS610 wetting and dispersing agent , 0.2 parts of hydroxyethyl cellulose, 0.2 parts of DF681F defoamer, 0.3 parts of RS preservative, 0.2 parts of AN130 PH regulator, 0.1 part of A401 alkali swelling thickener, 3 parts of film-forming aids, 8 parts of melamine MEL, Pentaerythritol PER 10 parts, ammonium polyphosphate APP 22 parts, titanium dioxide 5 parts, tertiary vinegar emulsion 20 parts.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com