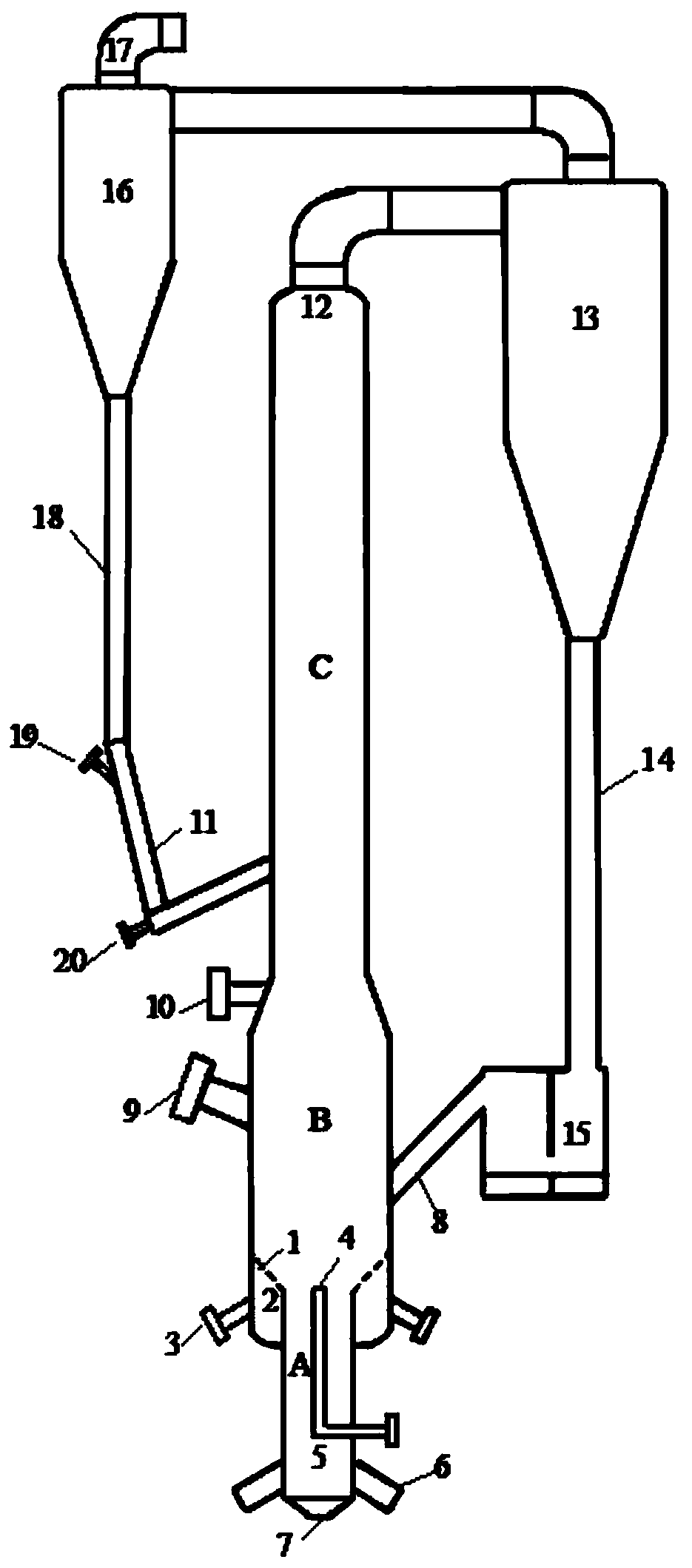

A high-throughput circulating fluidized bed low-rank coal gasification device and method

A circulating fluidized bed and coal gasification technology, which is applied in the gasification process, granular/powdered fuel gasification, and combustible gas production, etc. It can solve the problems of difficult ash discharge at the bottom, low carbon conversion rate, and low gasification intensity. , to achieve the effect of improving the device's processing capacity and gasification intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] In this embodiment, the ratio of the cross-sectional area of the carbon residue riser deep gasification zone C to the low-rank coal strong mixed pyrolysis, gasification, and combustion zone B is 0.5:1, and the outlet of the central jet tube 4 is connected to the V-shaped gas distribution plate 1 The bottom is equal in height.

[0026] The Mengdong lignite is sent to the pulverizing system, and after being crushed by the coal mill and dried by the dryer, the particle size is less than 15mm, and the moisture content is less than 10wt%. The coal feed pipe 9 in the middle of B is continuously fed into the furnace, and at the same time, the distribution plate inlet pipe 3, the central jet pipe 4, and the air inlet 7 of the separation column are continuously fed into the air at the bottom of the gasifier, and the low-rank coal is first cracked or pyrolyzed , and then part of the gasification or combustion reaction occurs, and the high-temperature semi-coke with a small part...

Embodiment 2

[0030] The cross-sectional area ratio of riser gasification zone C to strong mixing pyrolysis, gasification and combustion zone B is 0.75:1; the outlet of central jet tube 4 is slightly higher than the bottom of V-shaped gas distribution plate 1 . All the other devices are the same as those in Example 1.

[0031] In this example, Fuxin long-flame coal is fed into the pulverizing system, crushed by a coal mill and dried by a dryer so that the particle size is less than 15mm and the moisture content is less than 10wt%. The coal feed pipe 9 in the middle of the gasification / combustion zone B is continuously fed into the furnace, and at the same time, air is continuously fed into the distribution plate inlet pipe 3, the central jet pipe 4, and the air inlet 7 of the separation column at the bottom of the gasifier, and the low-rank coal First crack or pyrolyze, then partly gasify or burn, and generate high-temperature semi-coke with small particle size, which enters the riser gasif...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com