Point-shaped needle composite surface layer hot melting anti-scouring network structure and machining technology

A technology of acupuncture composite and network structure, used in geotextiles, water conservancy projects, marine engineering and other directions, can solve the problems of low peeling strength, detachment and falling off, and overall functional failure, and achieve the effect of eliminating free fibers and strengthening peeling strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in further detail below in conjunction with the accompanying drawings and with reference to the data. It should be understood that the embodiments are only for illustrating the present invention and not limiting the scope of the present invention in any way.

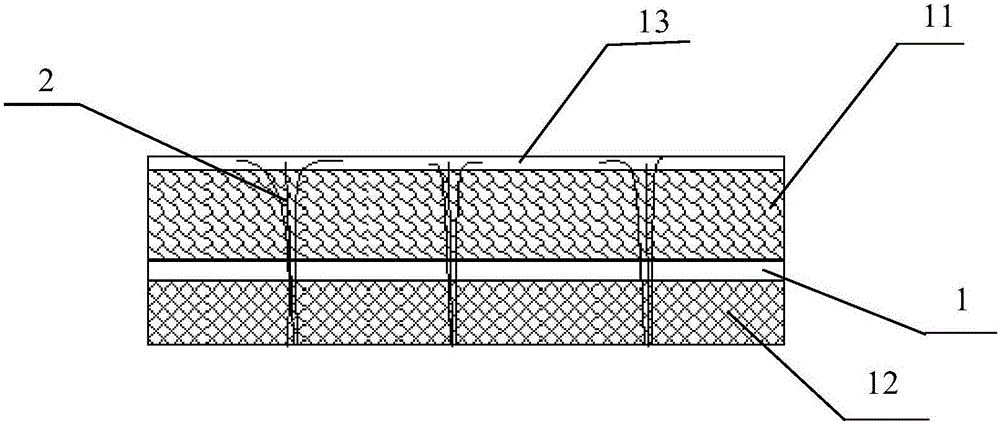

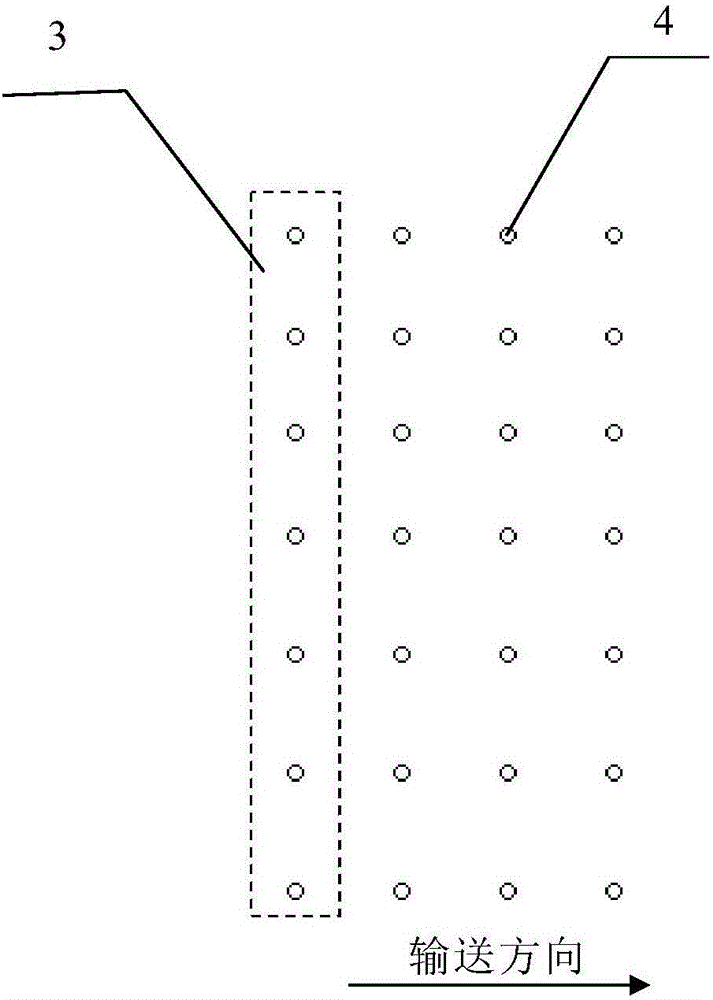

[0026] Such as figure 1 As shown, the present invention discloses a dot-shaped needle-punched composite surface hot-melt anti-scouring network structure, including laminated multi-layer textile materials, the multi-layer textile materials include top layer heat-melt textile materials and bottom non-woven fabrics, multi-layer The textile material is compounded by dotted needle punching on the reverse side, the area of the dotted needled parts is less than 10% of the total area, the end of the punctured fiber bundle from the bottom non-woven fabric at the dotted needled point and the upper surface of the top layer of heat-melt textile material Through hot-melt bonding, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com