Method for analyzing metal elements in electronic waste

A technology of electronic waste and analysis method, which is applied in the field of analysis and testing, can solve the problems of mutual interference of elements, large residues, incomplete dissolution of non-metals, etc., and achieve the effect of ensuring accuracy and avoiding unstable analysis results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

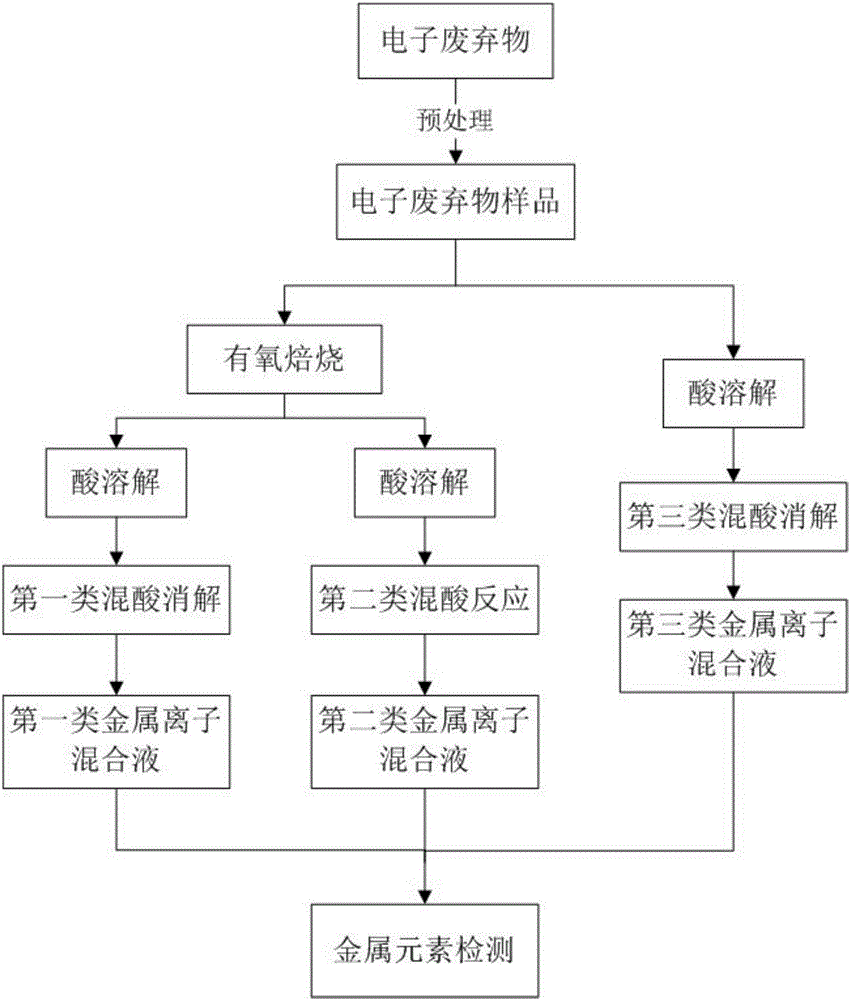

Method used

Image

Examples

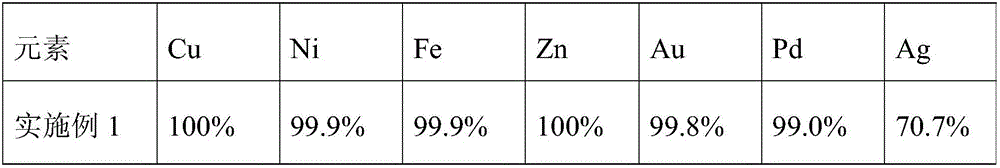

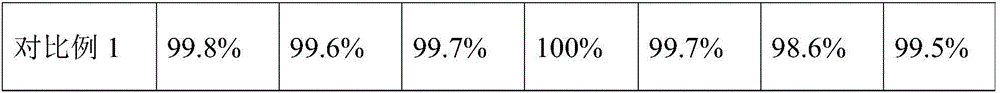

Embodiment 1

[0101] The present embodiment provides a method for analyzing metal elements in a computer motherboard, said method comprising the following steps:

[0102] (1) After the computer motherboard is mechanically crushed and screened, the powder particle size is kept between 80 meshes;

[0103] (2) Place the computer motherboard after mechanical crushing and sieving in step (1) in a high-temperature muffle furnace, maintain the temperature in the muffle furnace at 650° C. under a sufficient oxygen atmosphere, and keep the temperature for 6 hours to obtain a computer motherboard sample;

[0104] (3) Choose 10g of the computer motherboard sample in step (2), add concentration to be 65wt% concentrated nitric acid 20mL and let stand for 2h in the polytetrafluoroethylene digestion tank, then add HNO successively 3 10mL of concentrated aqua regia with a concentration of 35wt%, 5mL of hydrofluoric acid with a concentration of 45wt%, and 10mL of hydrogen peroxide with a concentration of 30...

Embodiment 2

[0110] The present embodiment provides a method for analyzing metal elements in a TV motherboard, said method comprising the following steps:

[0111] (1) After mechanically crushing and sieving the main board of the TV set, the particle size of the powder is kept between 120 mesh;

[0112] (2) Put the TV mainboard that has been mechanically crushed and screened in step (1) in a high-temperature muffle furnace, and keep the temperature in the muffle furnace at 450° C. for 1 hour under a sufficient oxygen atmosphere to obtain a TV Motherboard samples;

[0113] (3) Select 0.5g of the TV motherboard sample in step (2), add 5mL of concentrated nitric acid with a concentration of 65wt% in a polytetrafluoroethylene digestion tank and let it stand for 0.5h, then add HNO successively 3 The volume ratio of HCl and HCl is 1:3, 5mL of concentrated aqua regia with a concentration of 30wt%, 0.5mL of hydrofluoric acid with a concentration of 45wt%, and 5mL of hydrogen peroxide with a conce...

Embodiment 3

[0119] The present embodiment provides a method for analyzing metal elements in a mainboard of a mobile phone, said method comprising the following steps:

[0120] (1) After the main board of the mobile phone is mechanically crushed and screened, the powder particle size is kept between 200 mesh;

[0121] (2) Place the mobile phone main board that has been mechanically crushed and screened in step (1) in a high-temperature muffle furnace, and keep the temperature in the muffle furnace at 850°C under a sufficient oxygen atmosphere, and keep it warm for 3 hours to obtain a mobile phone main board sample ;

[0122] (3) Select 5g of the mobile phone motherboard sample in step (2), add 10mL of concentrated nitric acid with a concentration of 65wt% in a polytetrafluoroethylene digestion tank and let it stand for 12h, then add HNO 3 2mL of concentrated aqua regia with a concentration of 30wt%, 0.5mL of hydrofluoric acid with a concentration of 45wt%, and 5mL of hydrogen peroxide wit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Powder size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com