Touch screen silver paste and preparation method thereof

A technology of touch screen and silver paste, which is applied in cable/conductor manufacturing, instrument, electrical digital data processing, etc. It can solve the problems of restricting the development of touch screen, high cost, etc., to ensure the conductivity, improve the hardness and scratch resistance, and the preparation method is simple Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

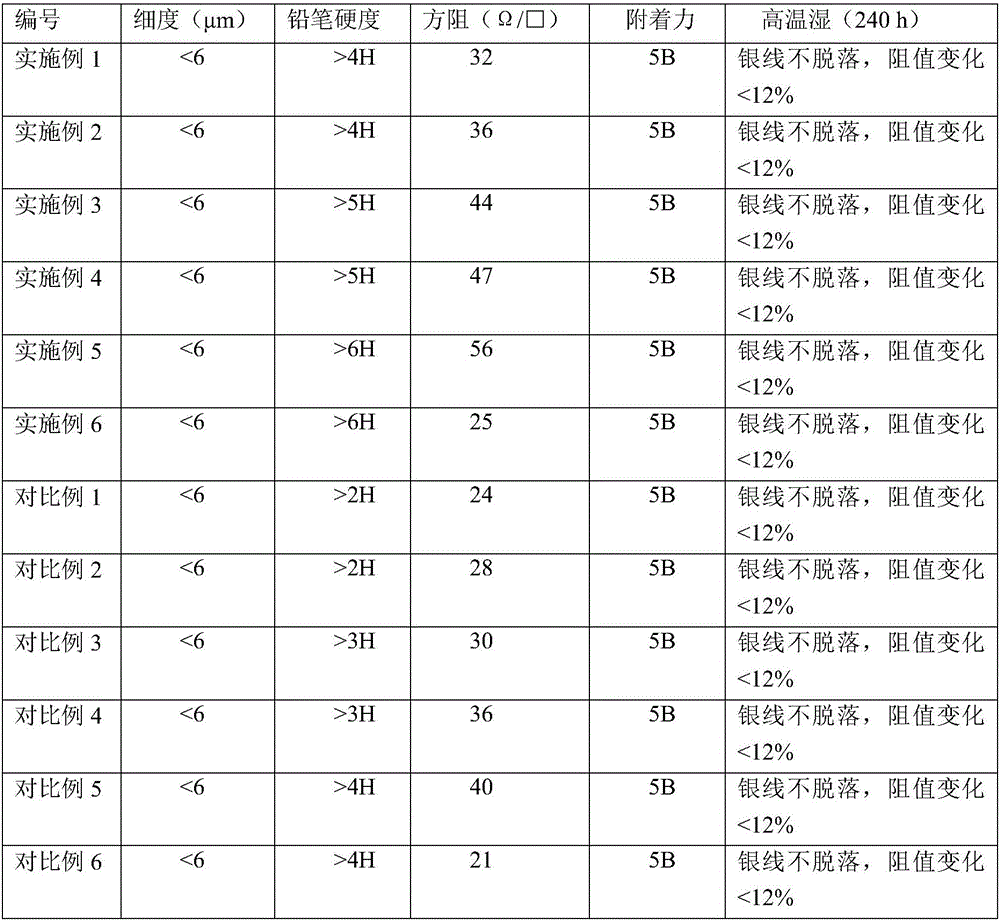

Examples

Embodiment 1

[0025] A touch screen silver paste, comprising the following components by weight: 58 g of silver powder, zirconium hydride (ZrH 2 ) 10g, polyester resin 10g, butyl butyrate 20g, nano-silica 2g.

[0026] The preparation method of touch screen silver paste in this embodiment includes the following steps:

[0027] a. Add 10 g of polyester resin to 20 g of butyl butyrate, heat and stir at 75°C for 2 hours, until the polyester resin is completely dissolved, and filter with a 300-mesh filter to remove insoluble matter to obtain an organic carrier;

[0028] b. Take 58 g of silver powder with a particle size of 0.8 to 5 μm and ZrH with a particle size of 3 to 5 μm 2 10g of powder, 2g of nano-silica, added to the organic carrier in step a, uniformly dispersed with a planetary dispersing mixer at 30°C, rolled with a three-roll mill for 10 passes, and then filtered with a 450-mesh filter to remove insoluble matter, Get touch screen silver paste.

Embodiment 2

[0030] A touch screen silver paste, comprising the following components by weight: 53 g of silver powder, zirconium hydride (ZrH 2 ) 15g, polyurethane 10g, diethylene glycol ethyl ether acetate 20g, methyl benzoate 2g.

[0031] The preparation method of touch screen silver paste in this embodiment includes the following steps:

[0032] a. Add 10 g of polyurethane to 20 g of diethylene glycol ethyl ether acetate, heat and stir at 75°C for 2 hours until the polyurethane is completely dissolved, and filter with a 300-mesh filter to remove insoluble matter to obtain an organic carrier;

[0033] b. Take 53 g of silver powder with a particle size of 0.8 to 5 μm and ZrH with a particle size of 3 to 5 μm 2 15g of powder, 2g of methyl benzoate, added to the organic carrier in step a, uniformly dispersed with a planetary dispersing mixer at 30°C, rolled with a three-roll mill for 10 passes, and then filtered with a 450-mesh filter to remove insoluble matter, Get touch screen silver pa...

Embodiment 3

[0035] A touch screen silver paste, comprising the following components by weight: 48 g of silver powder, zirconium hydride (ZrH 2) 20g, polyacrylic acid resin 15g, diethylene glycol methyl ether 25g, polyethylene glycol 5g.

[0036] The preparation method of touch screen silver paste in the present embodiment comprises the following steps:

[0037] a. Add 15 g of polyacrylic acid resin to 25 g of diethylene glycol methyl ether, heat and stir at 70° C. for 2.5 h until the polyester resin is completely dissolved, and filter with a 350-mesh filter to remove insoluble matter to obtain an organic carrier;

[0038] b. Take 48g of silver powder with a particle size of 0.8-5μm and ZrH with a particle size of 3-5μm 2 Add 20g of powder and 5g of polyethylene glycol to the organic carrier in step a, disperse evenly with a planetary dispersion mixer at 35°C, roll 8 passes with a three-roll mill, and then filter with a 500-mesh filter to remove insoluble matter. Get touch screen silver ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com