Flaky carbonyl functionalized carbon material, preparation method thereof and application thereof in preparation of supercapacitor

A functional and carbon material technology, applied in the manufacture of hybrid capacitor electrodes, hybrid/electric double layer capacitors, etc., can solve the problems of poor capacitance performance and capacity, long application differences, low efficiency, etc., and achieve low cost, low price, cost reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

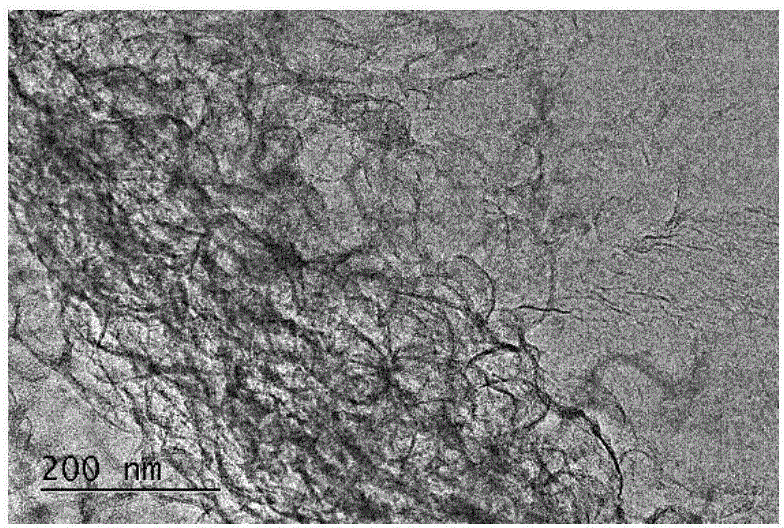

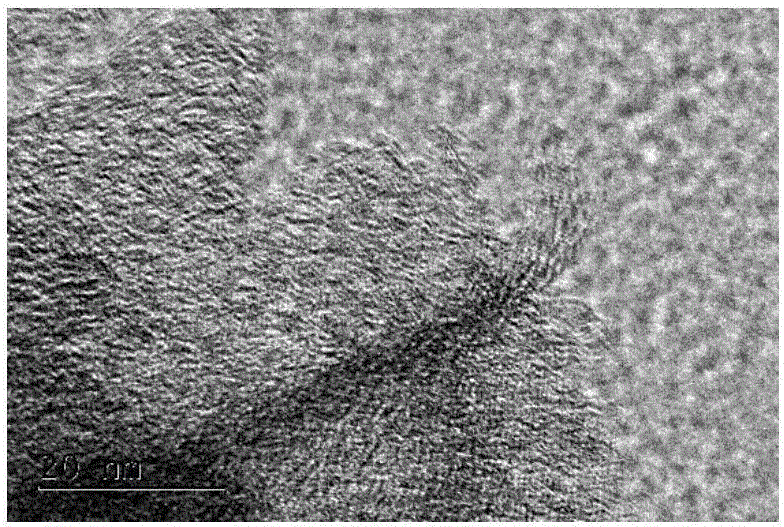

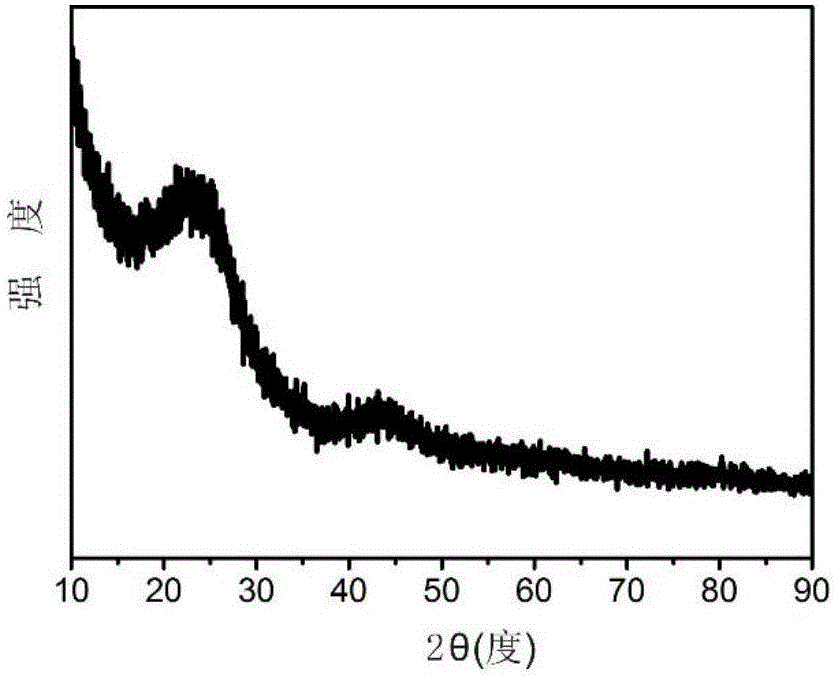

[0042] 0.94g of phenol was dissolved in 20ml of water to obtain a precursor solution with a concentration of 0.5mol / L, and then 2.5ml of formaldehyde (37%) was added to the precursor solution and mixed uniformly to obtain a mixed precursor solution. The prepared mixed precursor solution was impregnated onto calcium hydroxide by incipient wetness impregnation and kept for 72 hours to obtain a mixture of oligomeric resin / calcium hydroxide, and the mixture of oligomeric resin / calcium hydroxide was thermoset at 120°C After 48 hours a cured resin / calcium hydroxide mixture was obtained. The obtained cured resin / calcium hydroxide mixture was roasted in an argon atmosphere at 600°C for 4 hours to obtain a carbon / calcium oxide composite structure, and the carbon / calcium oxide composite structure was placed in 100ml of hydrochloric acid with a concentration of 0.2mol / L Carrying out etching to remove calcium oxide, then carrying out suction filtration, washing and drying to obtain a thin...

Embodiment 2

[0044]1.11 g of catechol was dissolved in 10.0 ml of water to obtain a precursor solution with a concentration of 1.0 mol / L, and then 2.5 ml of formaldehyde (37%) was added to the precursor solution and mixed uniformly to obtain a mixed precursor solution. The prepared mixed precursor solution was impregnated onto magnesium hydroxide by incipient wetness impregnation and kept for 48 hours to obtain a mixture of oligomeric resin / magnesium hydroxide, and the mixture of oligomeric resin / magnesium hydroxide was thermoset at 100°C After 24 h a cured resin / magnesium hydroxide mixture was obtained. The obtained cured resin / magnesium hydroxide mixture was roasted in an argon atmosphere at 700°C for 2 hours to obtain a carbon / magnesia composite structure, and the carbon / magnesia composite structure was placed in 100ml of hydrochloric acid with a concentration of 0.2mol / L Carry out etching to remove magnesia, then carry out suction filtration, wash and dry to obtain the carbon material ...

Embodiment 3

[0046] 1.26g of trisphenol was dissolved in 5.0ml of water to obtain a precursor solution with a concentration of 2.0mol / L, and then 2.5ml of formaldehyde (37%) was added to the precursor solution and mixed uniformly to obtain a mixed precursor solution. The prepared mixed precursor solution was impregnated onto magnesium hydroxide by incipient wetness impregnation and kept for 24 hours to obtain a mixture of oligomeric resin / magnesium hydroxide, and the mixture of oligomeric resin / magnesium hydroxide was thermoset at 80°C After 12 h a cured resin / magnesium hydroxide mixture was obtained. The obtained cured resin / magnesium hydroxide mixture was roasted in an argon atmosphere at 800°C for 1 hour to obtain a carbon / magnesia composite structure, and the carbon / magnesia composite structure was placed in 100ml of hydrochloric acid with a concentration of 0.2mol / L Carry out etching to remove magnesia, then carry out suction filtration, wash and dry to obtain the carbon material of f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com