Ternary lithium-ion battery cathode material improved by active oxide multiply and preparation method thereof

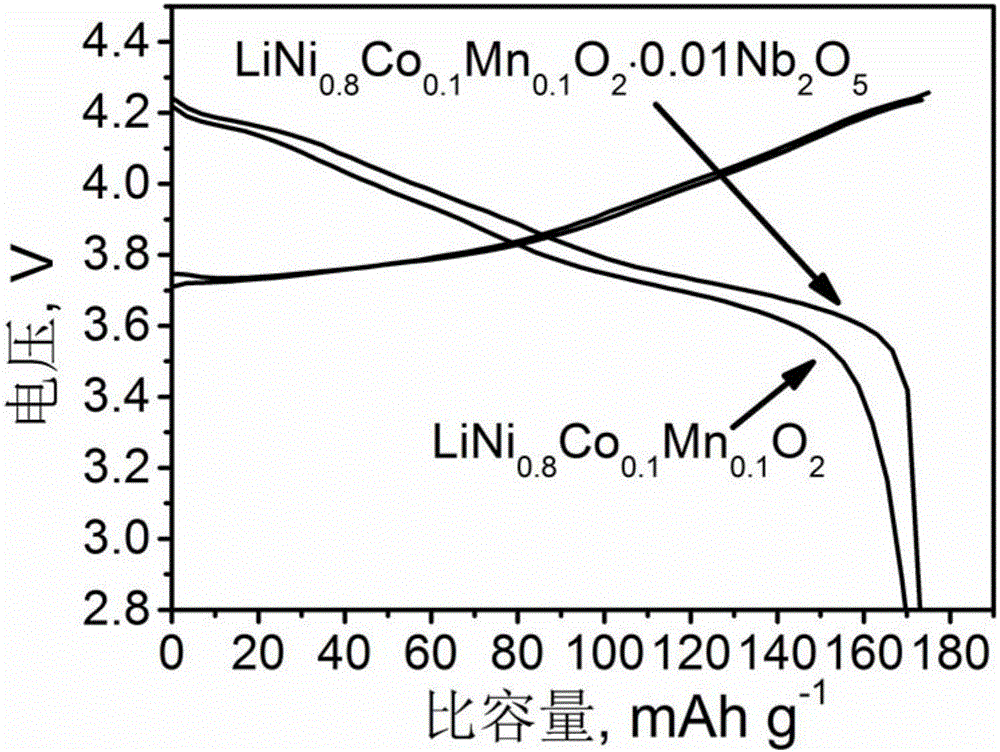

An active oxide, lithium-ion battery technology, applied in battery electrodes, electrical components, circuits, etc., can solve the problem of reducing the discharge specific capacity and energy density, the oxide has no electrochemical activity, and the material cycle stability is not much improved. and other problems, to achieve the effect of improving rate performance and cycle performance, improving performance in all aspects, and improving lithium ion transmission rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

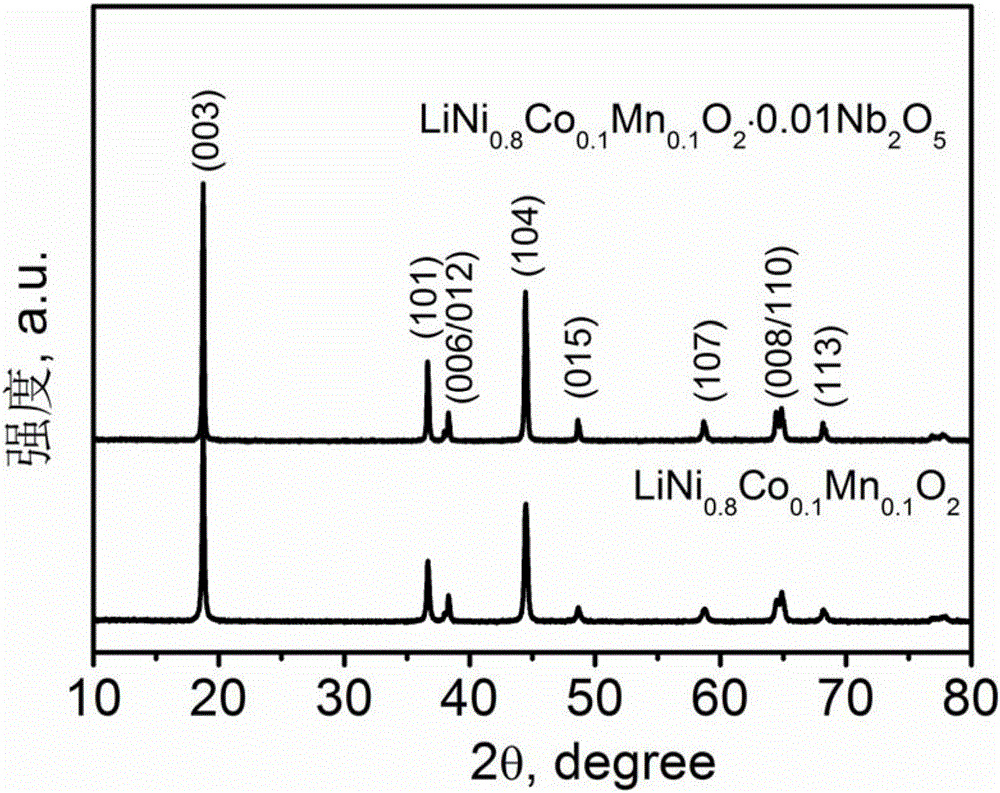

[0042] Provide a ternary positive electrode material for lithium-ion batteries with multiple active oxides, the chemical formula is LiNi 1-a- b co a mn b o 2 · cNb 2 o 5 , where a, b, and c are the number of moles, 02 o 5 for active oxides.

[0043] The active oxide multi-improves the ternary positive electrode material of the lithium-ion battery, and is prepared by the following steps:

[0044] (1) Preparation of nickel-cobalt-manganese hydroxide precursor material Ni by liquid-phase co-precipitation method 1-a-b co a mn b (OH) 2 ;

[0045] (2) In terms of molar ratio, take the niobium source according to the ratio of Nb:(Ni+Co+Mn)=2c:1, add a dispersant, and make a dispersant mixed solution with a concentration of 0.001~0.5mol / L. The nickel-cobalt-manganese hydroxide precursor material prepared in the above step (1) is put into the mixed solution of the dispersant, stirred for 0.5-5 hours, and then evaporated to dryness under constant stirring, so that the niobiu...

Embodiment 2

[0054] Provided is a method for preparing active oxide multiple-improved lithium-ion battery ternary cathode materials, which is prepared through the following steps,

[0055] (1) Preparation of nickel-cobalt-manganese hydroxide precursor material Ni by liquid-phase co-precipitation method 1-a-b co a mn b (OH) 2 ;

[0056] (2) In terms of molar ratio, take the niobium source according to the ratio of Nb:(Ni+Co+Mn)=2c:1, add a dispersant, and make a dispersant mixed solution with a concentration of 0.001~0.5mol / L. The nickel-cobalt-manganese hydroxide precursor material prepared in the above step (1) is put into the mixed solution of the dispersant, stirred for 0.5-5 hours, and then evaporated to dryness under constant stirring, so that the niobium source is adsorbed on the nickel-cobalt-manganese hydroxide The surface of the precursor material is obtained to obtain the precursor material of nickel cobalt manganese hydroxide adsorbed by niobium;

[0057] (3) According to t...

Embodiment 3

[0060] Provided is a method for preparing active oxide multiple-improved lithium-ion battery ternary cathode materials, which is prepared through the following steps,

[0061] (1) Preparation of nickel-cobalt-manganese hydroxide precursor material Ni by liquid-phase co-precipitation method 1-a-b co a mn b (OH) 2 ;

[0062] (2) In terms of molar ratio, the metal ion ratio of the lithium source and the nickel-cobalt-manganese hydroxide precursor material is Li: (Ni+Co+Mn)=1~1.1:1 ratio, the lithium source and the nickel-cobalt Manganese hydroxide precursor materials are mixed, then put into the mixing tank, after mixing for 2-20 hours, heat pretreatment at 400-700°C for 2-10 hours under oxygen or dry air atmosphere, and then heat up to 750-950°C Sintering for 10 to 30 hours, and naturally cooling to room temperature to obtain an uncoated positive electrode material;

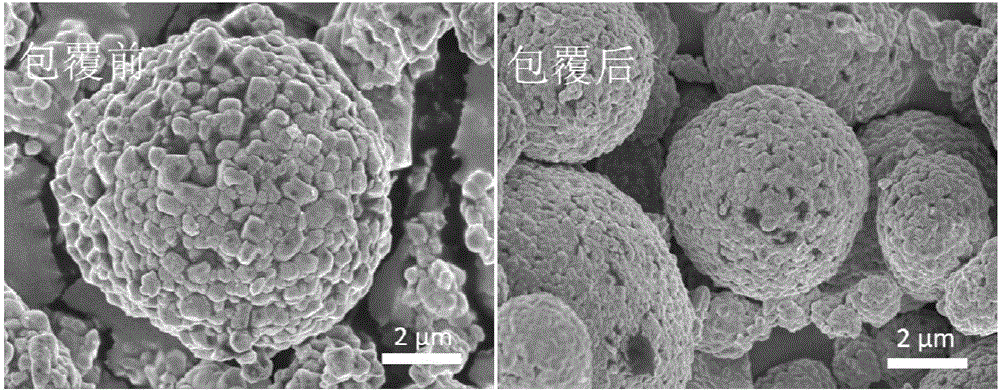

[0063] Weigh the niobium source according to the ratio of Nb:(Ni+Co+Mn)=2c:1, add a dispersant to prepare a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com