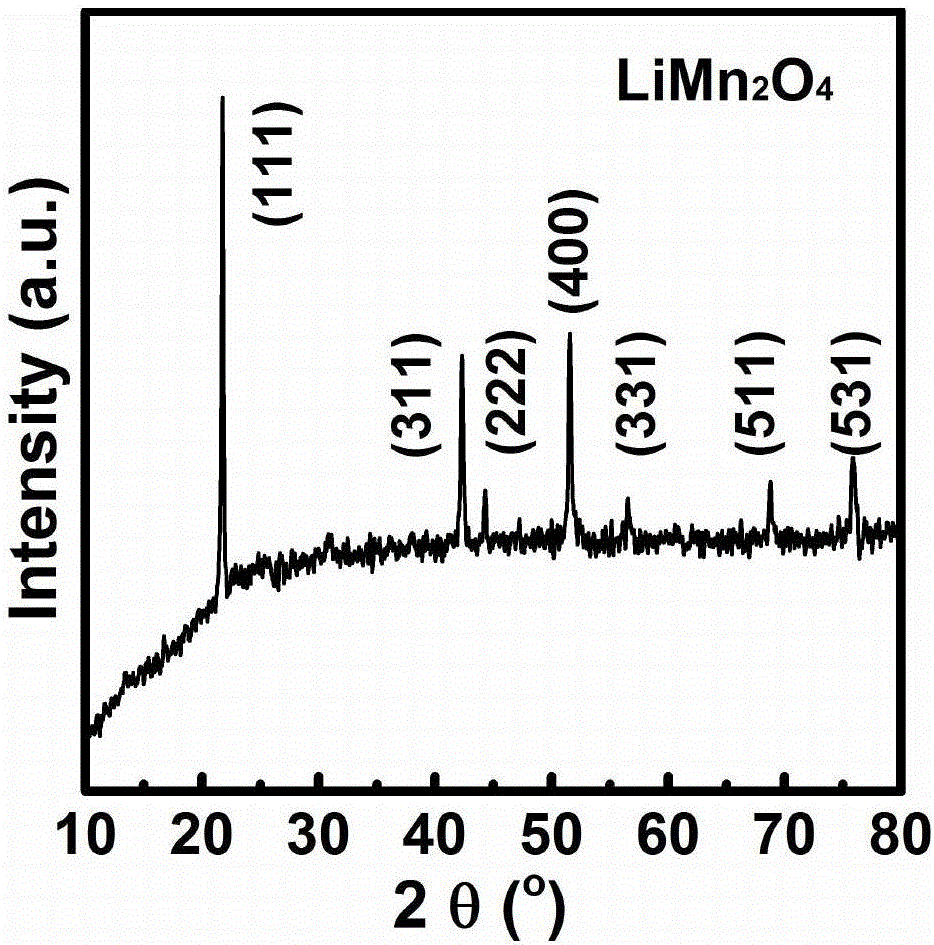

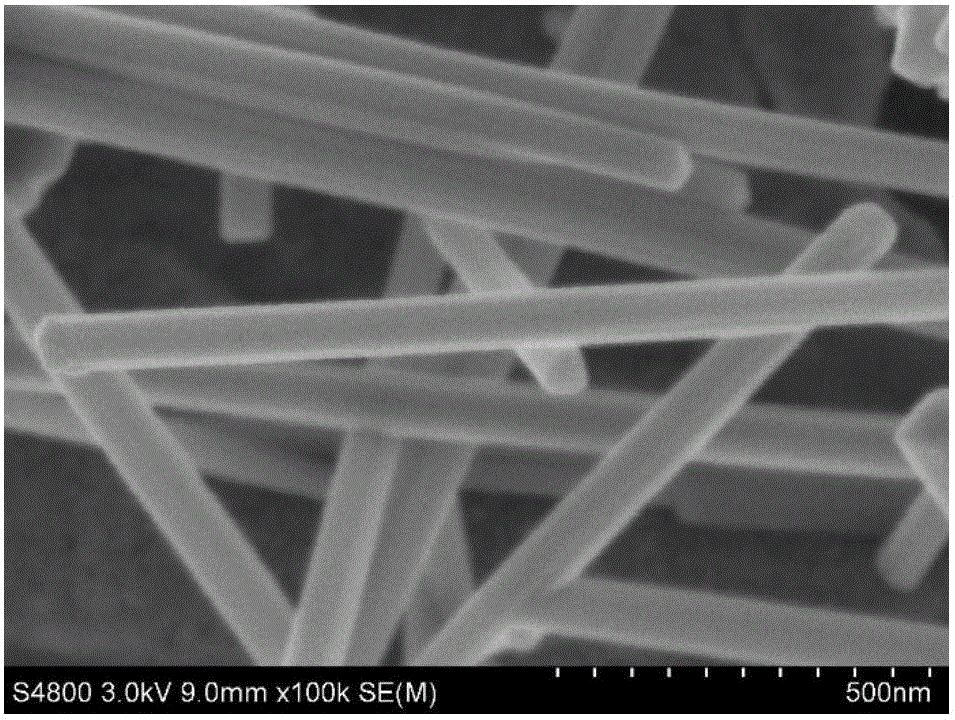

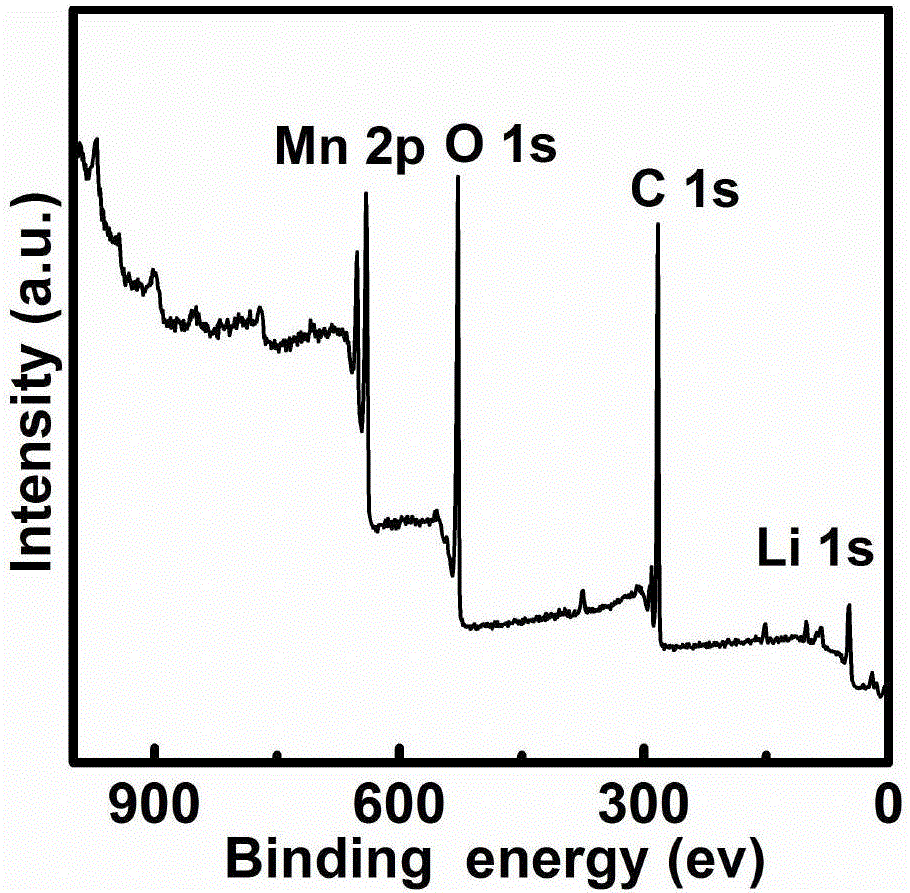

Preparation of C-coated LiMn2O4 nanowire with high-temperature solid-state method

A technology of carbon-coated lithium manganate and high-temperature solid-phase method, which is applied in nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve the problems that violate the original intention of nanomaterial preparation, and achieve improved cycle stability High performance, improved lithium battery performance, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] Step 1: Calcining 1 part of manganese sulfate and 15 parts of potassium nitrate at 380° C. in air for 3 hours to obtain a precursor of manganese oxide nanowires;

[0019] Step 2: Put 0.01g of glucose and 0.01g of precursor in a hydrothermal axe, react at 180°C for 2h, and coat the carbon layer on the surface of manganese oxide nanowires;

[0020] Step 3: 2.05 parts of carbon-coated manganese oxide nanowires and 1 part of lithium hydroxide were solid-phase sintered at 500° C. for 5 hours to obtain carbon-coated lithium manganate nanowires.

Embodiment 2

[0022] Step 1: Calcining 1 part of manganese sulfate and 15 parts of potassium nitrate at 380° C. in air for 3 hours to obtain a precursor of manganese oxide nanowires;

[0023] Step 2: Put 0.1g glucose and 0.1g precursor in a hydrothermal axe, react at 180°C for 2h, and coat the carbon layer on the surface of manganese oxide nanowires;

[0024] Step 3: 2.05 parts of carbon-coated manganese oxide nanowires and 1 part of lithium hydroxide were solid-phase sintered at 600° C. for 4 hours to obtain carbon-coated lithium manganate nanowires.

Embodiment 3

[0026] Step 1: Calcining 1 part of manganese sulfate and 15 parts of potassium nitrate at 380° C. in air for 3 hours to obtain a precursor of manganese oxide nanowires;

[0027] Step 2: Put 2g of glucose and 2g of the precursor in a hydrothermal axe, react at 180°C for 2h, and coat the carbon layer on the surface of the manganese oxide nanowires;

[0028] Step 3: 2.05 parts of carbon-coated manganese oxide nanowires and 1 part of lithium hydroxide were solid-phase sintered at 700° C. for 2 hours to obtain carbon-coated lithium manganate nanowires.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com