Mixed heat dissipation apparatus used for high-power optical fiber amplifier

A fiber amplifier and cooling device technology, applied in lasers, laser parts, phonon exciters, etc., can solve problems such as fiber fusing and affecting the safety of laser systems, and achieve uniform temperature field, low noise, high reliability and operational effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

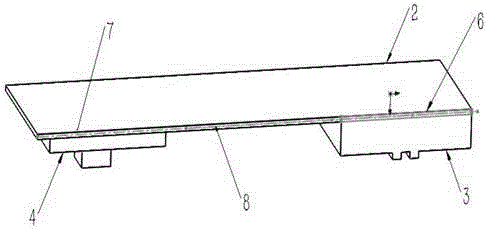

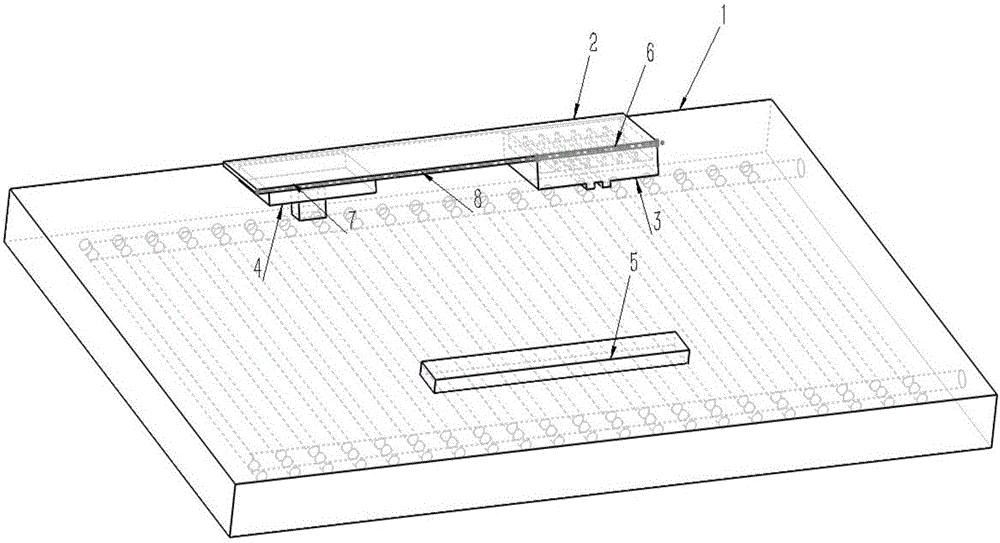

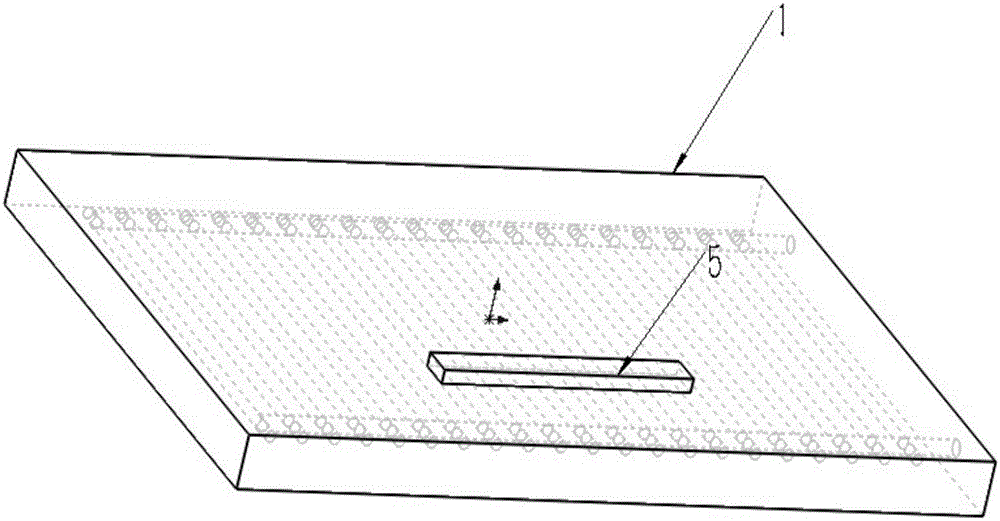

[0017] The hybrid heat dissipation device of the present invention includes a grid-like cooling plate and a radiator. V-shaped grooves are etched on the surface of the grid-like cooling plate for placing optical fibers. There are transverse and longitudinal holes inside the cooling plate. There is a cooling medium; the lower surface of the radiator is coated on the optical fiber fusion point, and the upper surface is bonded to the steam chamber of the nanoporous material heat pipe. In the heat pipe, the steam chamber is connected to the condensation chamber through a nanoporous membrane; the The lower surface of the condensation chamber is attached to the upper surface of the heat sink.

[0018] The device is mainly based on the high thermal conductivity of the nanoporous membrane. After the liquid in the steam chamber 6 evaporates, the steam quickly diffuses to the condensation chamber 7 through the nanoporous membrane 8. The high capillary core pressure of the nanoporous memb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com