Preparation method of carboxylated carbon nanotube and PS (polystyrene) composite material

A polystyrene and carboxylated carbon technology, applied in the field of functionalized materials, can solve the problems of limiting the application of carbon nanotubes and being insoluble, and achieve the effects of less investment in reaction equipment, simple operation and superior performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

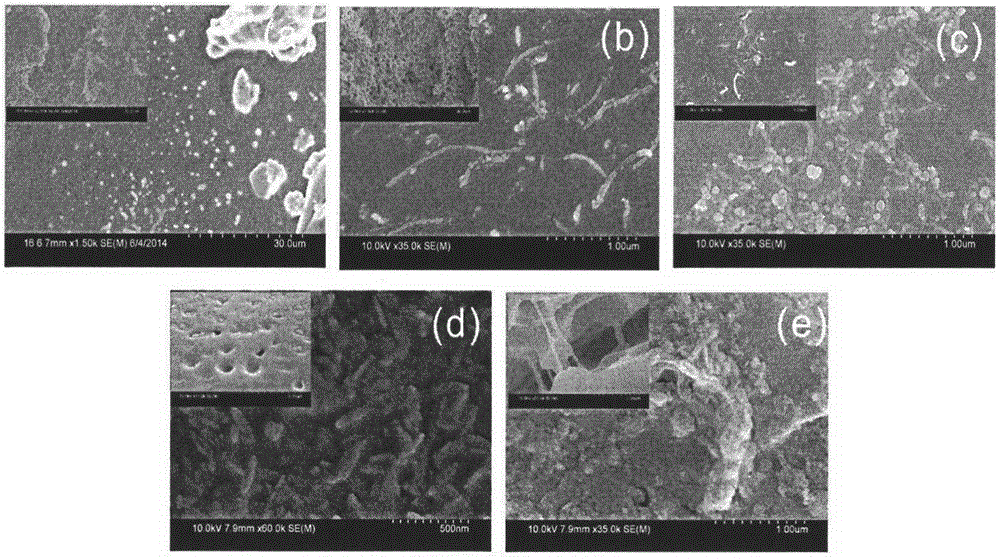

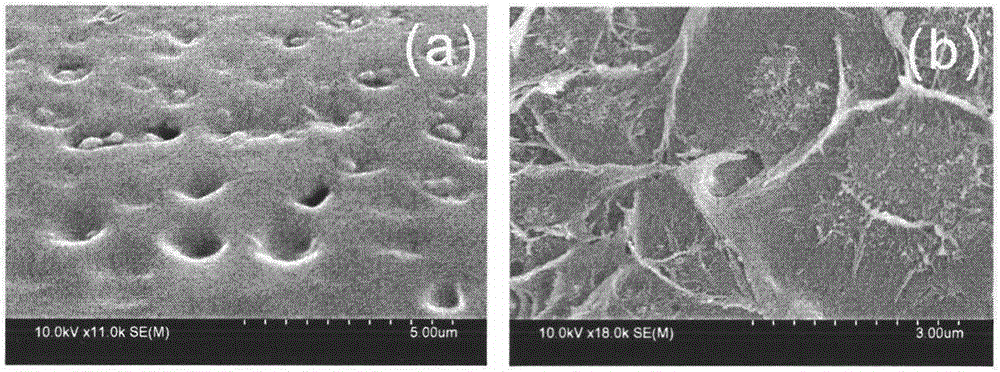

[0028] A preparation method of a composite material of carboxylated carbon nanotubes and polystyrene, the method steps are as follows:

[0029] 1) Multi-walled carbon nanotubes with carboxyl content of 0, 0.5, 2, 4, 8wt%, 0.1ml of surfactant Triton X-100, 5ml of tetrahydrofuran, stirred at 60° for 1h, controlled reaction temperature at 60° and sonicated for 1h.

[0030] 2) Dispersion: After adding PS and mechanically stirring to dissolve completely, ultrasonic wave is used for 0.5h until the carbon nanotubes are completely dispersed and evenly distributed.

[0031] 3) Film formation: Pour the mixed solution into a specific container (the diameter of the flange gasket is 5.5cm, and the height is 2mm). After 20 minutes, put the flange gasket into water to form a film, and the sample can be obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com