Axially-chiral aggregation-induced luminous compound as well as preparation method and application thereof

A compound and axial chirality technology, applied in the field of axial chiral compounds and their preparation, can solve the problems of product solubility easily affected by photo-oxidation, long synthetic route steps, large synthetic workload, etc., and achieves correct structure, good stability, The effect of high product yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] The reaction formula is as follows:

[0027]

[0028] Add 1.0g (2.9mmol) 2,2'-dihydroxy-[1,1'-binaphthyl]-3,3'-dialdehyde racemate, 50mL ethanol, 0.94g (6.0mmol) diethyl malonate and 0.25g (2.9mmol) piperidine were heated to reflux for 24h, cooled to room temperature, a solid precipitated, filtered, and dried to obtain 1.1g of a yellow powder product with a yield of 70%.

[0029] In the above examples, the racemate of 2,2'-dihydroxy-[1,1'-binaphthyl]-3,3'-dialdehyde was replaced by S-type 2,2'-dihydroxy-[1, 1'-binaphthyl]-3,3'-dialdehyde, and the other steps are exactly the same as those in the above examples to obtain the S-type product.

[0030] In the above examples, the racemate of 2,2'-dihydroxy-[1,1'-binaphthyl]-3,3'-dialdehyde was replaced by R-type 2,2'-dihydroxy-[1, 1'-binaphthyl]-3,3'-dialdehyde, and the other steps are exactly the same as in the above examples to obtain the R-type product.

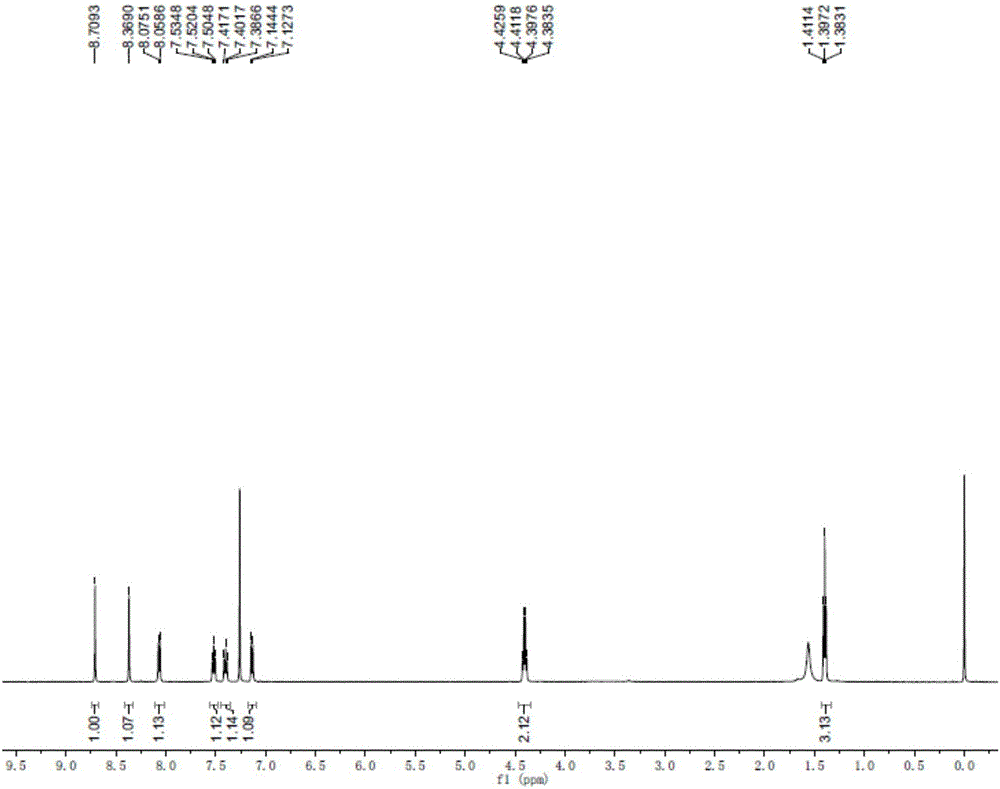

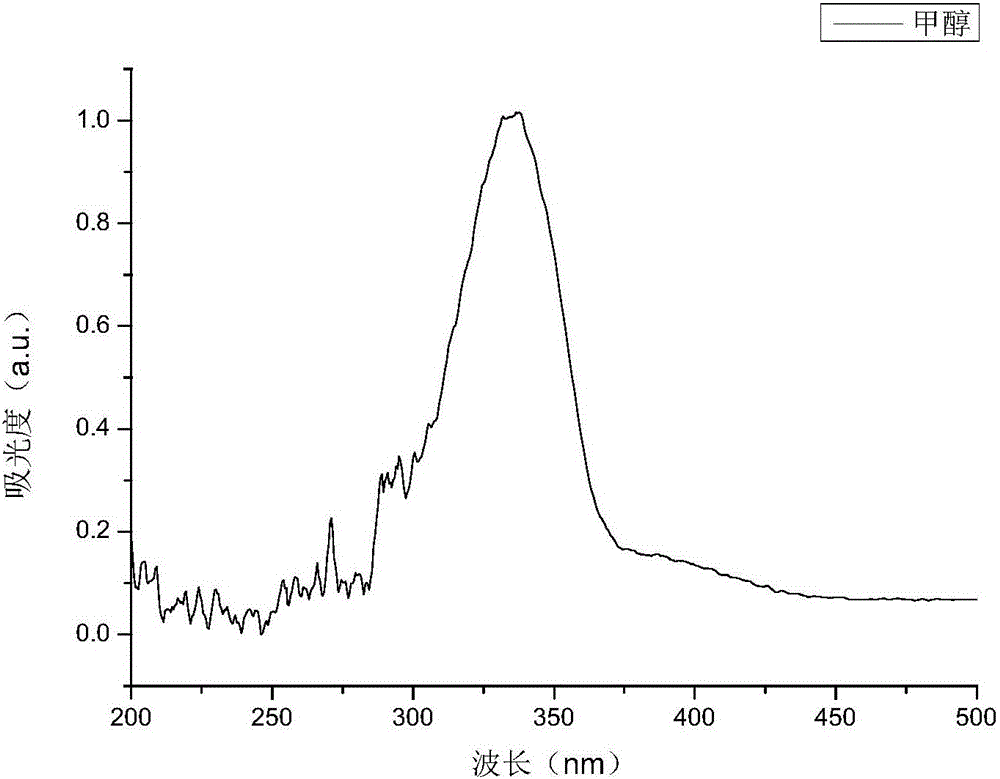

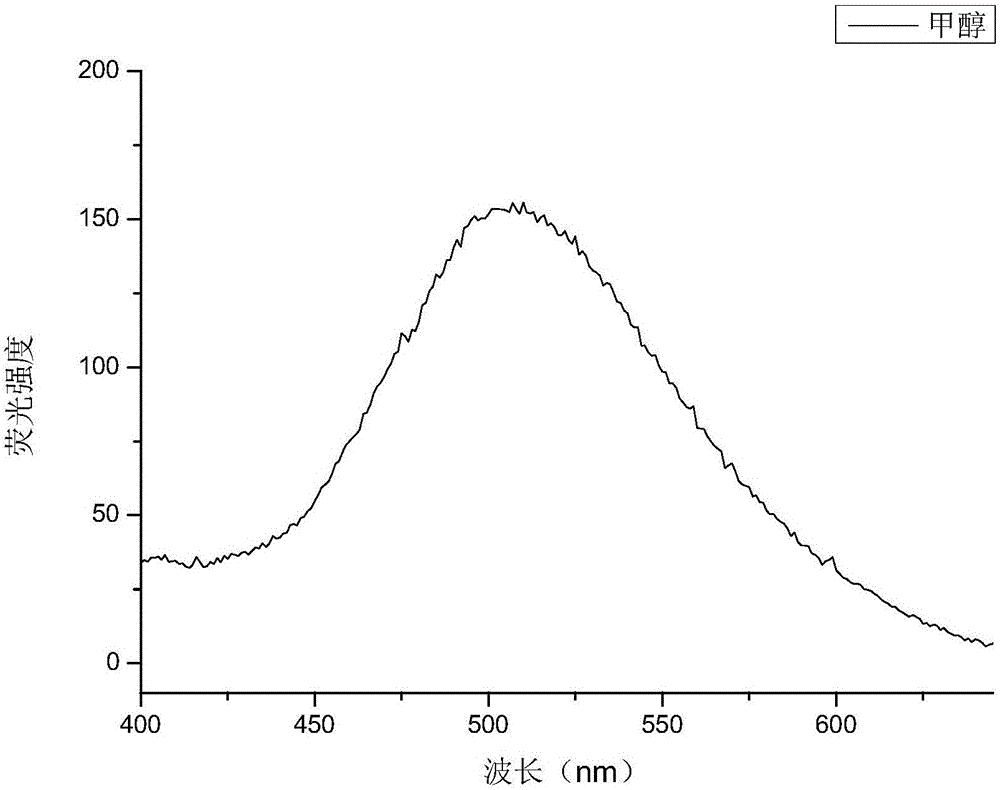

[0031] The structure detection result of this compound is as f...

Embodiment 2

[0037] The reaction formula is as follows:

[0038]

[0039]Add 1.0g (2.9mmol) 2,2'-dihydroxy-[1,1'-binaphthyl]-3,3'-dialdehyde racemate, 50mL ethanol, 0.78g (6.0mmol) ethyl acetoacetate and 0.25g (2.9mmol) piperidine were heated to reflux for 24h, cooled to room temperature, a solid precipitated, filtered and dried to obtain 1.0g of a yellow powder product with a yield of 73%.

[0040] In the above examples, the racemate of 2,2'-dihydroxy-[1,1'-binaphthyl]-3,3'-dialdehyde was replaced by S-type 2,2'-dihydroxy-[1, 1'-binaphthyl]-3,3'-dialdehyde, and the other steps are exactly the same as those in the above examples to obtain the S-type product.

[0041] In the above examples, the racemate of 2,2'-dihydroxy-[1,1'-binaphthyl]-3,3'-dialdehyde was replaced by R-type 2,2'-dihydroxy-[1, 1'-binaphthyl]-3,3'-dialdehyde, and the other steps are exactly the same as in the above examples to obtain the R-type product.

[0042] The structure detection result of this compound is as f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific rotation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com