Monodisperse spherical white-light fluorescent powder for white-light LED and preparing method of powder

A monodisperse, phosphor technology, used in chemical instruments and methods, luminescent materials, etc., can solve the problems of difficulty in obtaining spherical particles, wide particle size distribution, and large particle size of synthetic powders, and avoid difficulties in powder ratio. Control, good thermal stability of powder, good crystallinity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

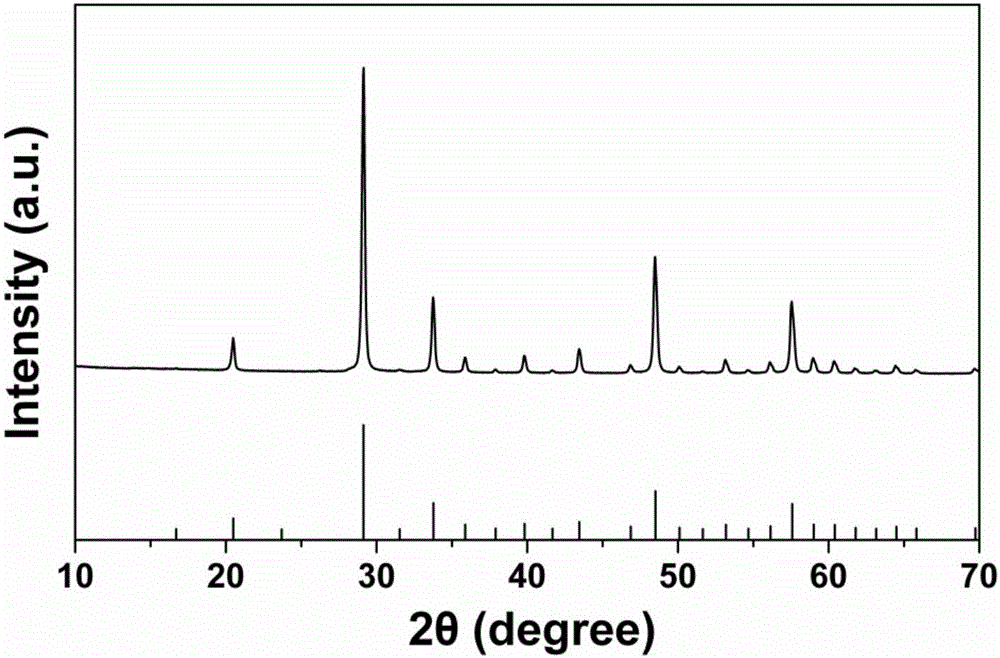

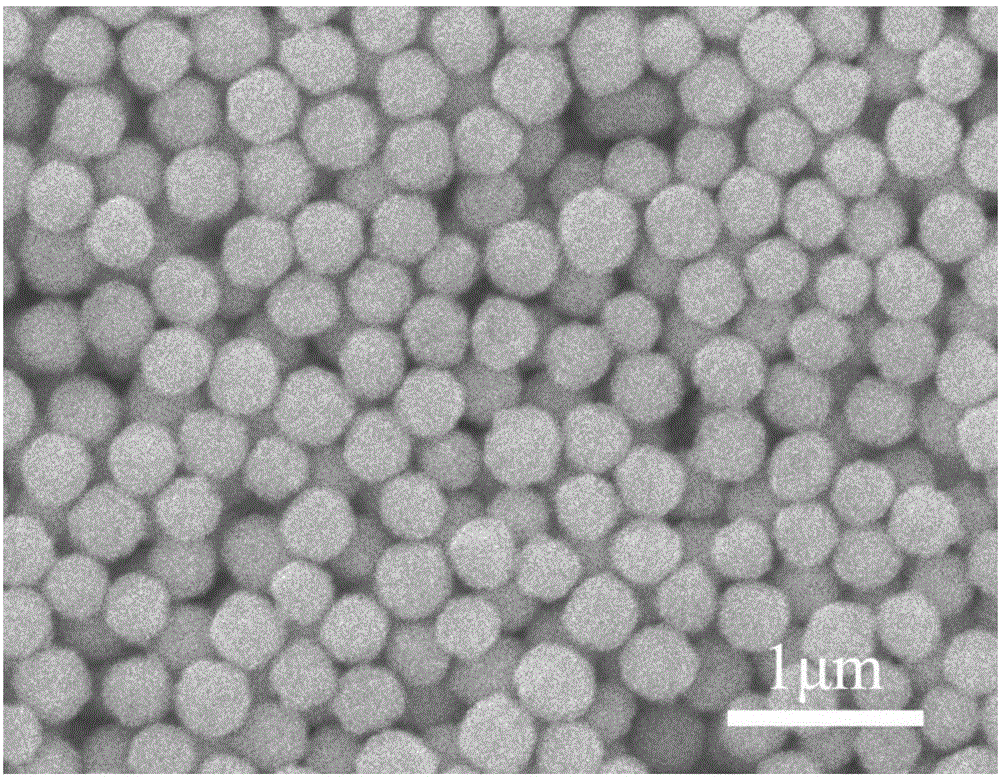

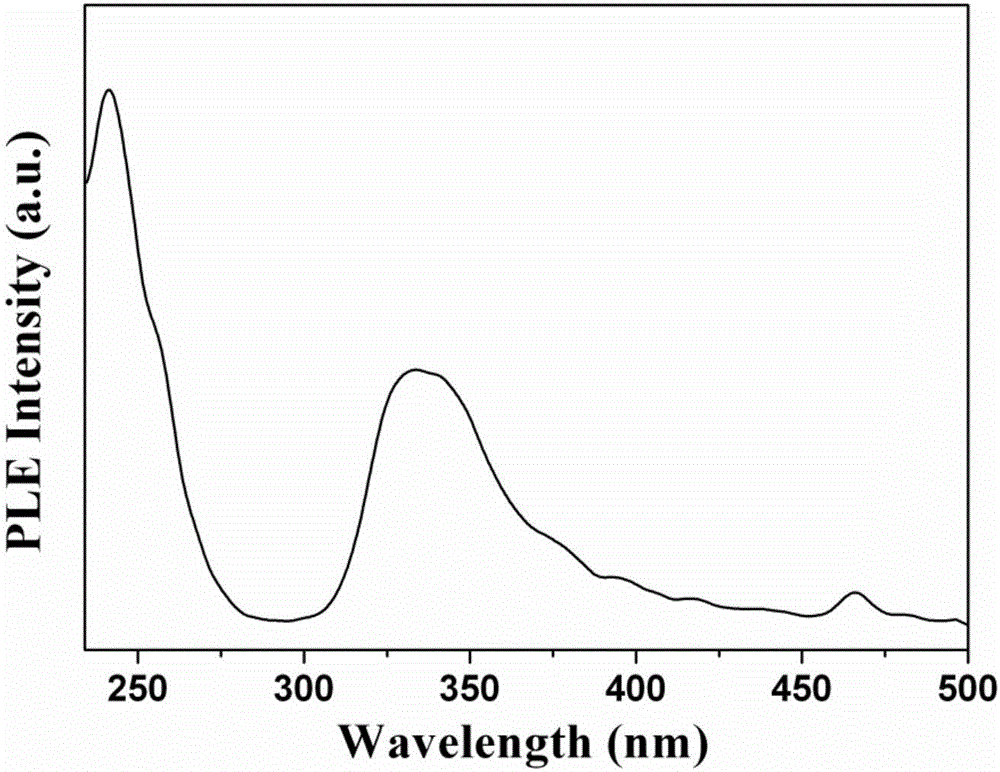

[0059] A kind of monodisperse spherical white light phosphor powder for white light LED, the chemical general formula of the monodisperse spherical white light phosphor powder for this white light LED is: (Y 0.991 Eu 0.001 Bi 0.008 ) 2 o 3 .

[0060] A preparation method of monodisperse spherical phosphor powder for white light LED, comprising the following steps:

[0061] Step 1, material preparation

[0062] According to the general chemical formula (Y 0.991 Eu 0001 Bi 0.008 ) 2 o 3 , respectively accurately weighed 6.0738g Y(NO 3 ) 3 ·6H 2 O (99.9%), 0.0071g Eu (NO 3 ) 3 ·6H 2 O(99.9%) and 0.0621g Bi(NO 3 ) 3 ·5H 2 0, the raw materials taken by weighing are mixed, adding 2L concentration is the dilute nitric acid solution of 0.027mol / L and fully dissolves, makes raw material mixed solution;

[0063] Step 2, add nitrogen-containing precipitant

[0064] Add 109.19g of urea into the raw material mixed solution, stir evenly, and the stirring time is 120min, ...

Embodiment 2

[0073] A kind of monodisperse spherical white light phosphor powder for white light LED, the chemical general formula of the monodisperse spherical white light phosphor powder for this white light LED is: (Y 0.9964 Eu 0.003 Bi 0.0006 ) 2 o 3 .

[0074] A preparation method of monodisperse spherical phosphor powder for white light LED, comprising the following steps:

[0075] Step 1, material preparation

[0076] According to the general chemical formula (Y 0.9964 Eu 0.003 Bi 0.0006 ) 2 o 3 , respectively accurately weigh 2.2500g Y according to the stoichiometric ratio 2 o 3 (99.99%), 0.0106g Eu 2 o 3 (99.99%) and 0.0058gBi (NO 3 ) 3 ·5H 2 0, raw materials are mixed, adding 2L concentration is the dilute nitric acid solution of 0.033mol / L and fully dissolves, makes raw material mixed solution;

[0077] Step 2, add nitrogen-containing precipitant

[0078] Add 96.096g of urea into the raw material mixed solution, stir evenly, and the stirring time is 45min, and ...

Embodiment 3

[0092] A kind of monodisperse spherical white light phosphor powder for white light LED, the chemical general formula of the monodisperse spherical white light phosphor powder for this white light LED is: (Y 0.989 Eu 0.008 Bi 0.003 ) 2 o 3 .

[0093] A preparation method of monodisperse spherical phosphor powder for white light LED, comprising the following steps:

[0094] Step 1, material preparation

[0095] According to the general chemical formula (Y 0.989 Eu 0.008 Bi 0.003 ) 2 o 3 , respectively accurately weigh 4.4665gY according to the stoichiometric ratio 2 o 3 (99.99%), 0.0563g Eu 2 o 3 (99.99%) and 0.0280g Bi 2 o 3 , mix the raw materials, add 2L of dilute nitric acid solution with a concentration of 0.062mol / L to fully dissolve, and obtain a mixed solution of raw materials;

[0096] Step 2, add nitrogen-containing precipitant

[0097] The urea of 10.51g and 2.00g ammonium nitrate are added in the raw material mixed solution, stir evenly, the stirr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com