Polyacrylonitrile modified starch nano-fiber and preparation method thereof

A technology of polyacrylonitrile and starch nanometers, applied in fiber treatment, fiber chemical characteristics, single-component synthetic polymer rayon, etc., can solve the problems of low strength and poor hydrophobicity, and achieve easy film formation and good hydrophobicity , Increase the effect of water solubility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] The invention provides a method for preparing polyacrylonitrile modified starch nanofibers, the specific preparation steps are as follows:

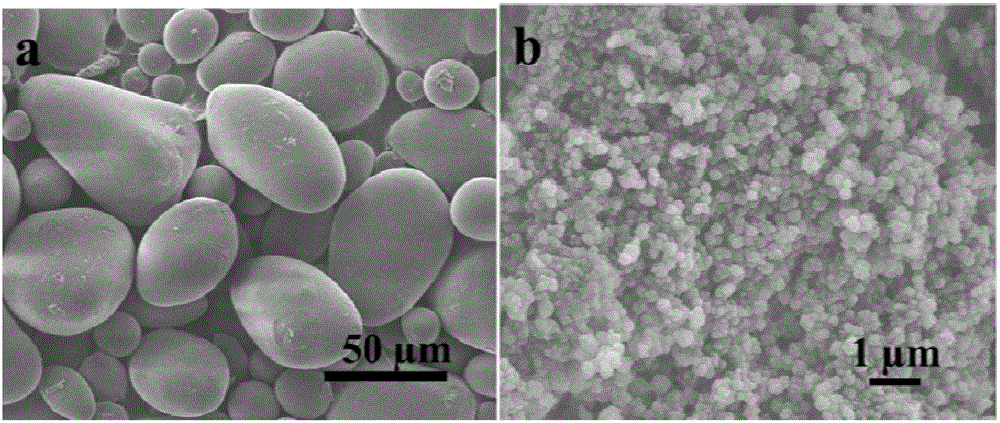

[0036] ① Preparation of starch grafted polyacrylonitrile polymer

[0037] 6.4g of soluble starch and 320mL of water were gelatinized at 80°C for 1 hour, then cooled to room temperature. Then in N 2 Under protection, add 3.3g ammonium cerium nitrate successively and adjust the pH value to 1 with nitric acid, after reacting for 1 hour, add 29mL acrylonitrile, N 2 React under protection for 2 hours, then soak and wash in DMF, and dry the obtained product at 60°C to obtain the target product;

[0038] ② Preparation of spinning solution for polyacrylonitrile modified starch polymer

[0039] Dissolving the starch-grafted acrylonitrile polymer obtained in step ① in DMSO, heating to 70° C. to dissolve to obtain a spinning solution containing 4.7wt% starch-grafted acrylonitrile polymer;

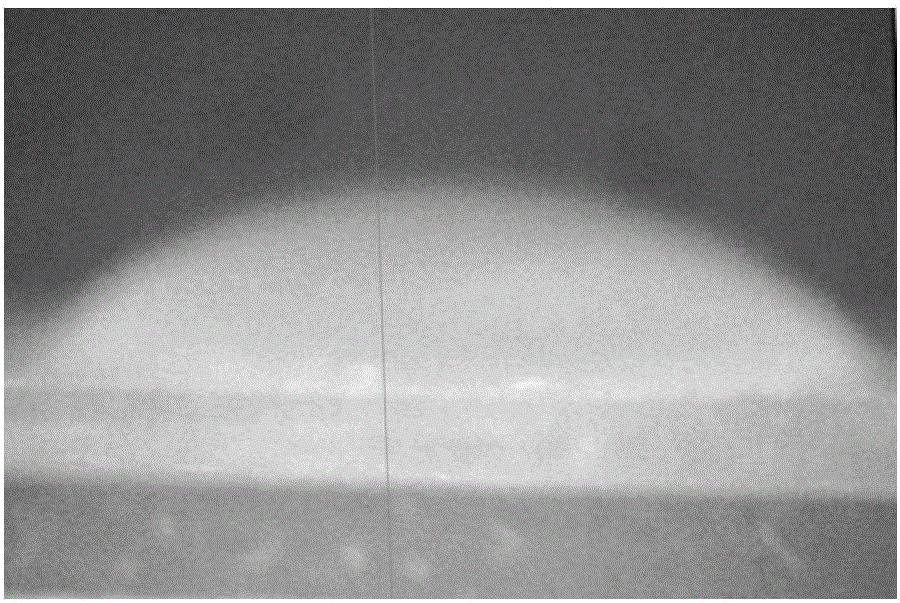

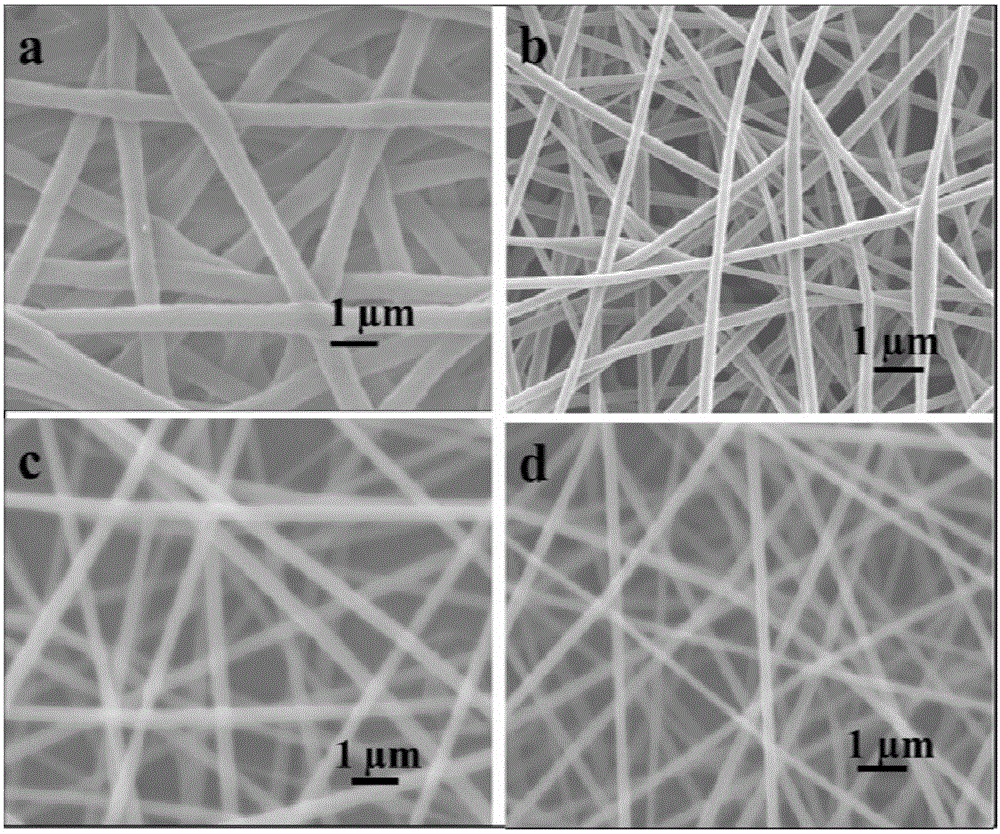

[0040] ③Nanofibers of polyacrylonitrile modified...

Embodiment 2

[0043] A method for preparing polyacrylonitrile modified starch nanofibers, the specific preparation steps are as follows:

[0044] ① Preparation of starch grafted polyacrylonitrile polymer

[0045] 6.4g of soluble starch and 320mL of water were gelatinized at 80°C for 1 hour, then cooled to room temperature. Then in N 2 Under protection, add 3.3g ammonium cerium nitrate successively and adjust the pH value to 1 with nitric acid, after reacting for 1 hour, add 29mL acrylonitrile, N 2 React under protection for 2 hours, then soak and wash in DMF, and dry the obtained product at 60°C to obtain the target product;

[0046] ② Preparation of spinning solution for polyacrylonitrile modified starch polymer

[0047] Dissolving the polymer obtained in step ① in dimethyl sulfoxide DMSO, heating to 70°C to dissolve to obtain a spinning solution containing 4.7wt% starch-grafted acrylonitrile polymer;

[0048] ③Nanofibers of polyacrylonitrile modified starch

[0049] Use a syringe to ...

Embodiment 3

[0051]A method for preparing polyacrylonitrile modified starch nanofibers, the specific preparation steps are as follows:

[0052] ① Preparation of starch grafted polyacrylonitrile polymer

[0053] 6.4g of soluble starch and 320mL of water were gelatinized at 80°C for 1 hour, then cooled to room temperature. Then in N 2 Under protection, add 3.3g ammonium cerium nitrate successively and adjust the pH value to 1 with nitric acid, after reacting for 1 hour, add 29mL acrylonitrile, N 2 React under protection for 2 hours, then soak and wash in DMF, and dry the obtained product at 60°C to obtain the target product;

[0054] ② Preparation of spinning solution for polyacrylonitrile modified starch polymer

[0055] Dissolving the starch-grafted acrylonitrile polymer obtained in step ① in DMSO, heating to 70° C. to dissolve to obtain a spinning solution containing 4.7wt% starch-grafted acrylonitrile polymer;

[0056] ③Nanofibers of polyacrylonitrile modified starch

[0057] Use a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com