Preparation method of in situ coating modified NCA cathode material

A technology of nickel cobalt lithium aluminate and cathode material, applied in battery electrodes, structural parts, electrical components, etc., can solve the problems of reducing the specific capacity of NCA materials, increasing the process and cost, and hindering the migration of lithium ions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] 26.5 g of tetrabutyl titanate was dissolved in 2 L of absolute ethanol and stirred for 10 min. Add 500g Ni to the solution 0.80 co 0.15 Al 0.05 (OH) 2 Precursor, 245g LiOH·H 2 O and 15g of citric acid were heated and stirred at 60°C to obtain a sol. The sol was dried in a blast drying oven at 110°C for 12 hours, and passed through a 300-mesh sieve after grinding. The sieved material was placed in a resistance furnace at 850°C for 12 hours. After the material was cooled to room temperature, it was taken out, crushed by airflow and passed through a 400-mesh sieve to obtain a surface-coated 1 wt.% Li 4 Ti 5 o 12 Nickel cobalt lithium aluminate cathode material.

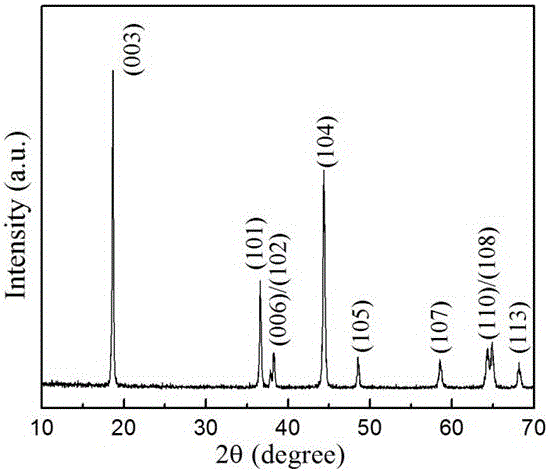

[0020] figure 1 Surface coating 1 wt.% Li prepared for Example 1 4 Ti 5 o 12 XRD pattern of nickel cobalt lithium aluminate cathode material. Coated Li 4 Ti 5 o 12 The XRD pattern of the material does not change significantly, and the two pairs of split peaks (006) / (102) and (110) / (108) are clearly...

Embodiment 2

[0023] Dissolve 15g of titanium tetrachloride in 2L of absolute ethanol and stir for 10min. Add 500g Ni to the solution 0.80 co 0.15 Al 0.05 (OH) 2 Precursor, 245g LiOH·H 2 O and 15g of citric acid were heated and stirred at 60°C to obtain a sol. The sol was dried in a blast drying oven at 110°C for 12 hours, and passed through a 300-mesh sieve after grinding. The sieved material was placed in a resistance furnace at 850°C for 12 hours. After the material was cooled to room temperature, it was taken out, crushed by air flow and passed through a 400-mesh sieve to obtain a surface-coated 1 wt.% Li 4 Ti 5 o 12 Nickel cobalt lithium aluminate cathode material.

[0024] The surface obtained in Example 2 is coated with 1 wt.% Li 4 Ti 5 o 12 The nickel cobalt lithium aluminate cathode material was tested by XRD. Test gained XRD pattern has and figure 1 Same feature: Coated Li 4 Ti 5 o 12 The XRD pattern of the material does not change significantly, and the two pairs ...

Embodiment 3

[0027] 53 g of tetrabutyl titanate was dissolved in 2 L of absolute ethanol and stirred for 10 min. Add 500g Ni to the solution 0.80 co 0.15 Al 0.05 (OH) 2 Precursor, 248g LiOH·H 2 O and 10g of glacial acetic acid were heated and stirred at 80°C to obtain a sol. The sol was dried in a blast drying oven at 110°C for 12 hours, and passed through a 300-mesh sieve after grinding. The sieved material was placed in a resistance furnace at 880°C for 15 hours. After the material was cooled to room temperature, it was taken out, crushed by air flow and passed through a 400-mesh sieve to obtain a surface-coated 2 wt.% Li 4 Ti 5 o12 Nickel cobalt lithium aluminate cathode material.

[0028] The surface obtained in Example 3 is coated with 2 wt.% Li 4 Ti 5 o 12 The nickel cobalt lithium aluminate cathode material was tested by XRD. Test gained XRD pattern has and figure 1 Same feature: Coated Li 4 Ti 5 o 12 The XRD pattern of the material does not change significantly, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com