Preparation method of chitosan synergistic antibacterial liquid

The technology of chitosan and antibacterial liquid is applied in the field of preparation of chitosan synergistic antibacterial liquid, which can solve the problems of low antibacterial ability and low water solubility, and achieve excellent antibacterial performance and improve antibacterial ability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

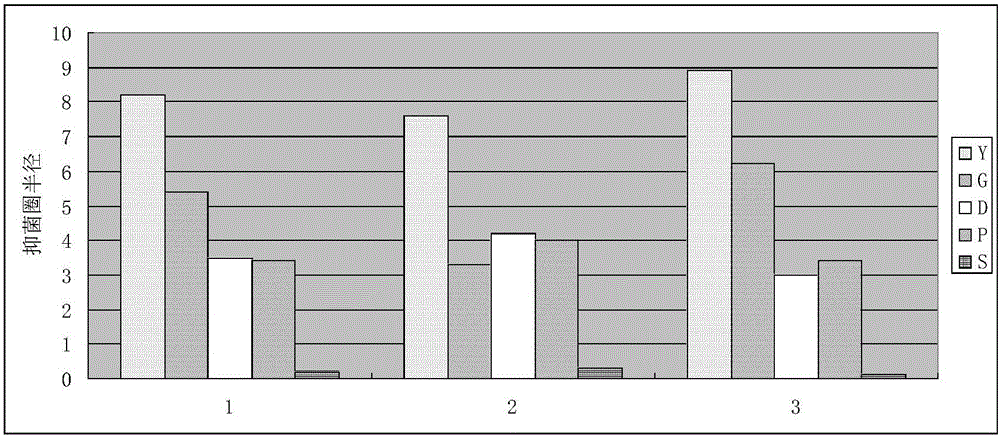

Image

Examples

preparation example Construction

[0020] A preparation method of chitosan synergistic antibacterial liquid, comprising the following steps:

[0021] (1) After compounding the mixture of 0.1g~20g high molecular weight chitosan and low molecular weight chitosan in proportion, dissolve it in 800mL~1000mL acetic acid solution, stir to form a transparent and uniform mixed solution, the high molecular weight chitosan The mass dosage ratio of polysaccharide to the low molecular weight chitosan is 3:1~10:1;

[0022] (2) Dissolve the compound of malic acid and sodium malate in distilled water in proportion, stir to form a complex aqueous solution, and the molar ratio of malic acid and sodium malate in the compound of malic acid and sodium malate is 5 : 1 to 5: 4, the mass dosage ratio of the compound of the malic acid and sodium malate to the distilled water is 1: 1000 to 3: 1000;

[0023] (3) Slowly add the complex aqueous solution obtained in step (2) dropwise into the mixed solution obtained in step (1), and stir i...

Embodiment 1

[0029] One, the preparation of chitosan synergistic antibacterial liquid

[0030] (1) After compounding the mixture of 2.5g high molecular weight chitosan (molecular weight is 30kDa) and low molecular weight chitosan (molecular weight is 5kDa) in proportion, dissolve in 1000ml, 1.5% acetic acid solution, stir to form transparent and uniform Mixed solution, wherein, the mass dosage ratio of high molecular weight chitosan and low molecular weight chitosan is 5: 1;

[0031] (2) Dissolve 1 g of the compound of malic acid and sodium malate in 1000 mL of distilled water in proportion, and stir evenly to form a complex aqueous solution, wherein the molar ratio of malic acid and sodium malate in the compound of malic acid and sodium malate is 5:1;

[0032] (3) Slowly drop the complex aqueous solution obtained in step (2) into the mixed solution obtained in step (1), and stir for 1 hour in a water bath at 50° C. to obtain the chitosan synergistic antibacterial liquid.

[0033] 2. Ant...

Embodiment 2

[0041] (1) After compounding the mixture of 5g high molecular weight chitosan (molecular weight is 30kDa) and low molecular weight chitosan (molecular weight is 5kDa) in proportion, dissolve in 1000ml, 1.5% acetic acid solution, stir to form transparent and uniform Mixed solution, the mass dosage ratio of high molecular weight chitosan and low molecular weight chitosan is 3: 1;

[0042] (2) The compound of 3g malic acid and sodium malate is dissolved in 1000mL distilled water in proportion, stirs to form complex aqueous solution, the molar ratio of malic acid and sodium malate in the compound of malic acid and sodium malate is 5 : 3;

[0043] (3) Slowly add the complex aqueous solution obtained in step (2) dropwise into the mixed solution obtained in step (1), and stir in a water bath at 55° C. for 3 hours to obtain chitosan synergistic antibacterial liquid.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com