Yttrium Oxide-Straw Cellulose Composite Nano Antibacterial Material

A technology of straw cellulose and antibacterial materials, which is applied in the fields of chemicals for biological control, sterilization/microdynamic water/sewage treatment, botanical equipment and methods, etc., can solve the problems of bacterial drug resistance, etc. Excellent antibacterial properties, high potential industrial application value, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

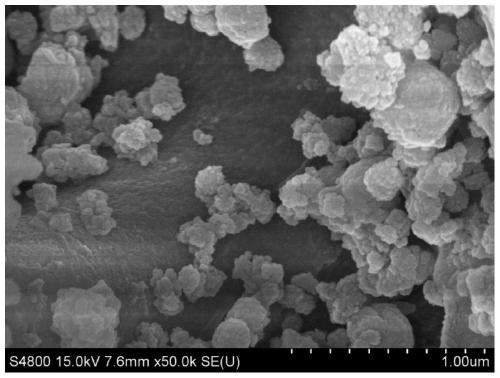

Image

Examples

Embodiment 1

[0036] The preparation and application of a novel yttrium oxide-stalk cellulose composite nano antibacterial material of the present invention comprises the following steps in turn:

[0037] (1) Weigh 10 g of straw slurry and suspend it with 1 L of aqueous solution containing 0.16 TEMPO and 1 g of NaBr;

[0038] (2) Utilize 0.1mol / L HCl to adjust the pH of the 5wt% NaClO solution to 10;

[0039] (3) Add the product of step (2) to the product of step (1) according to the ratio of 2.5mmol NaClO:1g straw slurry, and stir vigorously for 2 hours, during which the pH of the solution is adjusted with 0.5mol / L NaOH to keep the pH = 10;

[0040] (4) After the stirring is completed, fully wash with deionized water, then filter, after the stirring is completed, fully wash with deionized water, then filter, and then place it in an oven to dry, thereby obtaining straw cellulose;

[0041] (5) Weigh 1.552g of yttrium nitrate hexahydrate, 0.5g of polyvinylpyrrolidone and 10mg of the product...

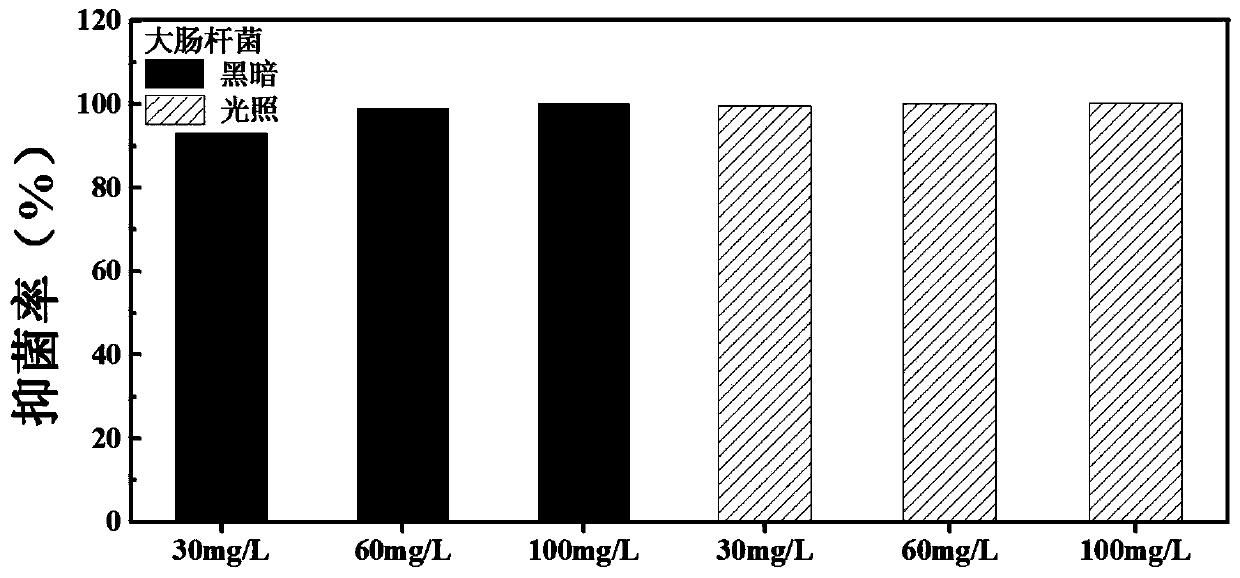

Embodiment 2

[0052] The preparation and application of a novel yttrium oxide-stalk cellulose composite nano antibacterial material of the present invention comprises the following steps in turn:

[0053] (1) Weigh 10 g of straw slurry and suspend it with 1 L of aqueous solution containing 0.16 TEMPO and 1 g of NaBr;

[0054] (2) Utilize 0.1mol / L HCl to adjust the pH of the 5wt% NaClO solution to 10;

[0055] (3) Add the product of step (2) to the product of step (1) according to the ratio of 2.5mmol NaClO:1g straw slurry, and stir vigorously for 2 hours, during which the pH of the solution is adjusted with 0.5mol / L NaOH to keep the pH = 10;

[0056] (4) After the stirring is completed, fully wash with deionized water, then filter, after the stirring is completed, fully wash with deionized water, then filter, and then place it in an oven to dry, thereby obtaining straw cellulose;

[0057] (5) Weigh 1.552g of yttrium nitrate hexahydrate, 0.5g of polyvinylpyrrolidone and 10mg of the product...

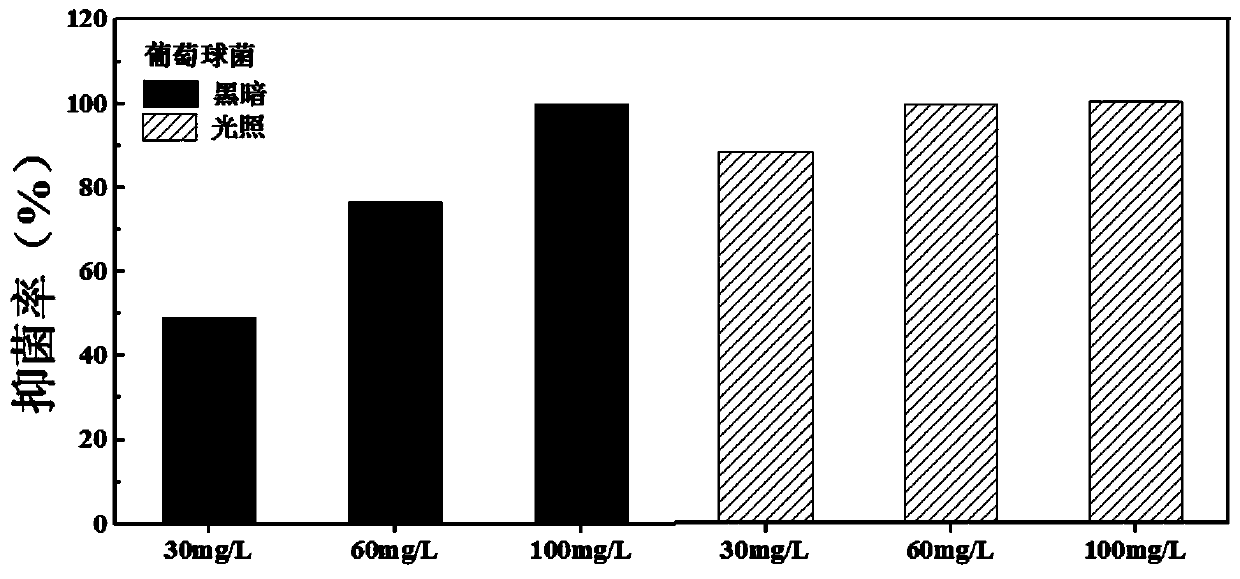

Embodiment 3

[0068] The preparation and application of a novel yttrium oxide-stalk cellulose composite nano antibacterial material of the present invention comprises the following steps in turn:

[0069] (1) Weigh 10 g of straw slurry and suspend it with 1 L of aqueous solution containing 0.16 TEMPO and 1 g of NaBr;

[0070] (2) Utilize 0.1mol / L HCl to adjust the pH of the 5wt% NaClO solution to 10;

[0071] (3) Add the product of step (2) to the product of step (1) according to the ratio of 2.5mmol NaClO:1g straw slurry, and stir vigorously for 2 hours, during which the pH of the solution is adjusted with 0.5mol / L NaOH to keep the pH = 10;

[0072] (4) After the stirring is completed, fully wash with deionized water, then filter, after the stirring is completed, fully wash with deionized water, then filter, and then place it in an oven to dry, thereby obtaining straw cellulose;

[0073] (5) Weigh 1.552g of yttrium nitrate hexahydrate, 0.5g of polyvinylpyrrolidone and 10mg of the product...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com