Moringa enzyme preparation method

A Moringa enzyme and technology of Moringa, applied in the direction of food science, etc., can solve the problems of incomplete utilization of Moringa nutritional value, low raw material utilization efficiency, and low content of functional components, so as to improve the utilization rate of raw materials and shorten the fermentation period. Cycle, chelating effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

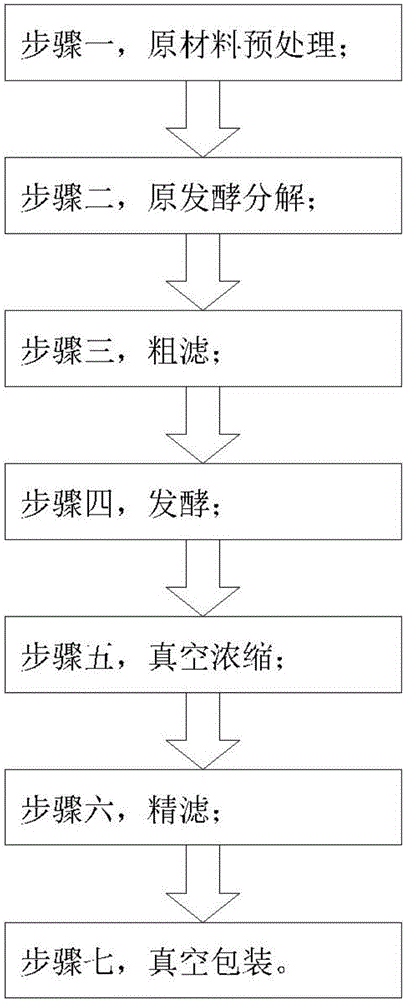

[0038] figure 1 The flow chart of the preparation method of Moringa ferment is provided for the present invention.

[0039] like figure 1 Shown, the preparation method of a kind of Moringa ferment that present embodiment provides, comprises the following steps:

[0040] A kind of preparation method of Moringa ferment that present embodiment provides, comprises the following steps:

[0041] Step 1, raw material pretreatment:

[0042] Moringa treatment: choose fresh, non-rotten and mildew-free, high-quality Moringa, which includes Moringa leaves, Moringa seeds, Moringa bark, and Moringa roots; clean, select, and drain the above-mentioned Moringa. Cut the bark and Moringa root into 5cm strips or blocks for later use, and use the Moringa seeds directly;

[0043] Processing of fruit and vegetable raw materials: select seasonal fresh vegetables and fruits, wash, select, drain, and slice for later use.

[0044] Step 2, fermentation and decomposition:

[0045] Fresh moringa and fr...

Embodiment 2

[0069] The present embodiment provides a kind of preparation method of Moringa ferment, comprises the following steps:

[0070] Step 1: Combine fresh moringa and fruit and vegetable raw materials in a weight ratio of 1:1, add brown sugar as a nutrient, (moringa + fruit and vegetable): brown sugar weight ratio 1:0.8; then mix and inoculate Rhizopus and Trichoderma , Cellulomonas, carry out solid-state fermentation, filter after the fermentation is completed, and obtain the fermentation filtrate; Rhizopus, Trichoderma, and Cellulomonas can combine cellulose, hemicellulose, lignin, and Starch and pectin components are decomposed;

[0071] The fermentation time is 15-20 days, and the fermentation temperature is 25-30°C. After the fermentation is completed, low-speed separation is carried out to obtain the filtrate;

[0072] Step 2: After adding sugar to the fermented filtrate, mix and inoculate the yeast group, acetic acid bacteria group, and lactic acid bacteria for graded ferme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com