Medicinal composition containing pimobendan and preparation method of medicinal composition

A technology of pimobendan and its composition, which is applied in the field of pimobendan-containing pharmaceutical composition and its preparation, can solve the problem of low solubility of pimobendan, achieve strong vasodilation and platelet aggregation, Improved solubility and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

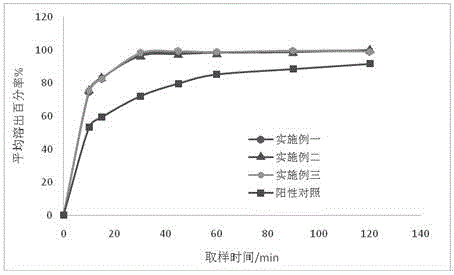

Examples

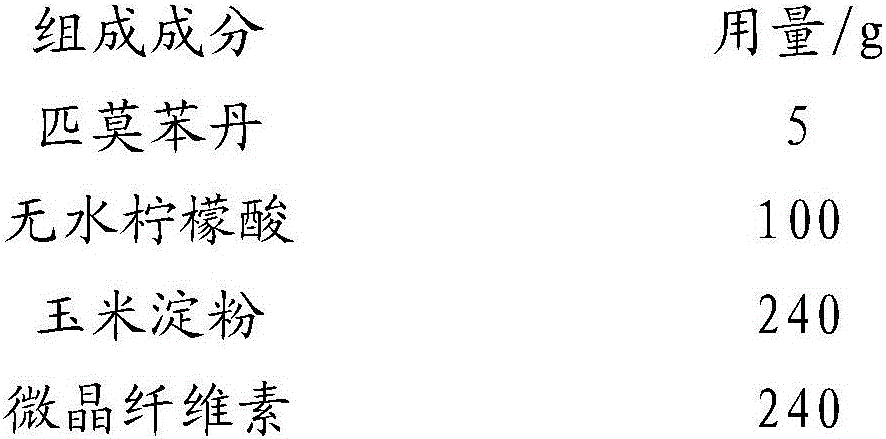

Embodiment 1

[0037]

[0038]

[0039] Preparation:

[0040] a) uniformly mix pimobendan and anhydrous citric acid in a ratio of 1:20, and ultrafinely pulverize them in an ultrafine pulverizer to obtain a micronized mixture with a particle size of 200 mesh;

[0041] b) Other ingredients are passed through a 100-mesh sieve respectively, and set aside;

[0042] c) mix a) with cornstarch, microcrystalline cellulose, 75% low-substituted hydroxypropyl cellulose, and beef powder in equal increments;

[0043] d) adding an aqueous solution of hypromellose to c) to make a soft material;

[0044] e) Perform wet granulation of the prepared soft material, dry at 65°C until the moisture content of the granules is about 3%, and granulate;

[0045] f) Add 25% low-substituted hydroxypropyl cellulose to e), and mix well;

[0046] g) adding micropowder silica gel and magnesium stearate to f), and mixing uniformly;

[0047] h) Compressing the obtained g) into tablets.

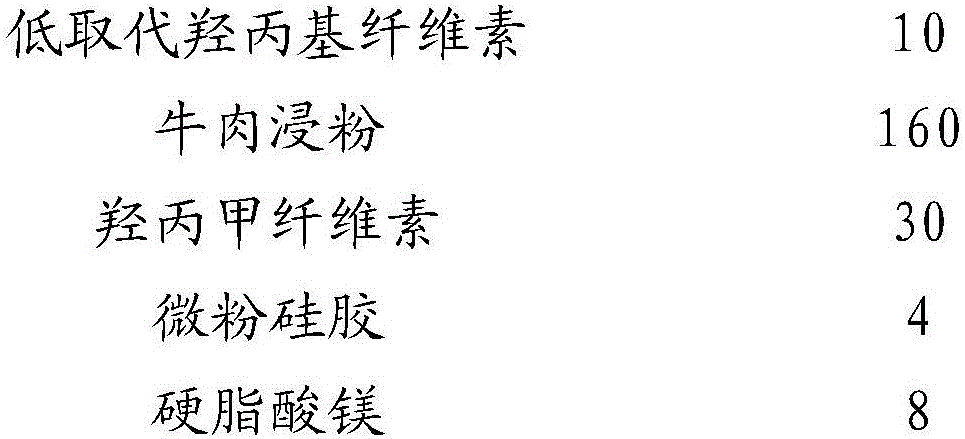

Embodiment 2

[0049]

[0050] Preparation:

[0051] a) uniformly mix pimobendan and anhydrous citric acid in a ratio of 1:20, and ultrafinely pulverize them in an ultrafine pulverizer to obtain a micronized mixture with a particle size of 400 mesh;

[0052] b) Other ingredients are passed through a 100-mesh sieve respectively, and set aside;

[0053] c) mix a) with cornstarch, microcrystalline cellulose, 75% low-substituted hydroxypropyl cellulose, and beef powder in equal increments;

[0054] d) adding an aqueous solution of hypromellose to c) to make a soft material;

[0055] e) Perform wet granulation of the prepared soft material, dry at 65°C until the moisture content of the granules is about 3%, and granulate;

[0056] f) Add 25% low-substituted hydroxypropyl cellulose to e), and mix well;

[0057] g) adding micropowder silica gel and magnesium stearate to f), and mixing uniformly;

[0058] h) Compressing the obtained g) into tablets.

Embodiment 3

[0060]

[0061] Preparation:

[0062] a) uniformly mix pimobendan and anhydrous citric acid according to the ratio of 1:20, and ultrafinely pulverize them in an ultrafine pulverizer to obtain a micronized mixture with a particle size of 300 mesh;

[0063] b) Other ingredients are passed through a 100-mesh sieve respectively, and set aside;

[0064] c) mix a) with cornstarch, microcrystalline cellulose, 75% low-substituted hydroxypropyl cellulose, and beef powder in equal increments;

[0065]d) adding an aqueous solution of hypromellose to c) to make a soft material;

[0066] e) Perform wet granulation of the prepared soft material, dry at 65°C until the moisture content of the granules is about 3%, and granulate;

[0067] f) Add 25% low-substituted hydroxypropyl cellulose to e), and mix well;

[0068] g) adding micropowder silica gel and magnesium stearate to f), and mixing uniformly;

[0069] h) Compressing the obtained g) into tablets.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com