Device for treating oil production sewage by gravity method and process thereof

A technology of oil extraction sewage and gravity method, applied in the field of oil extraction sewage treatment, can solve the problems of poor effluent quality, high energy consumption, short backwash interval, etc., and achieve the effects of good water quality, low operation cost, and improved oil production output.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

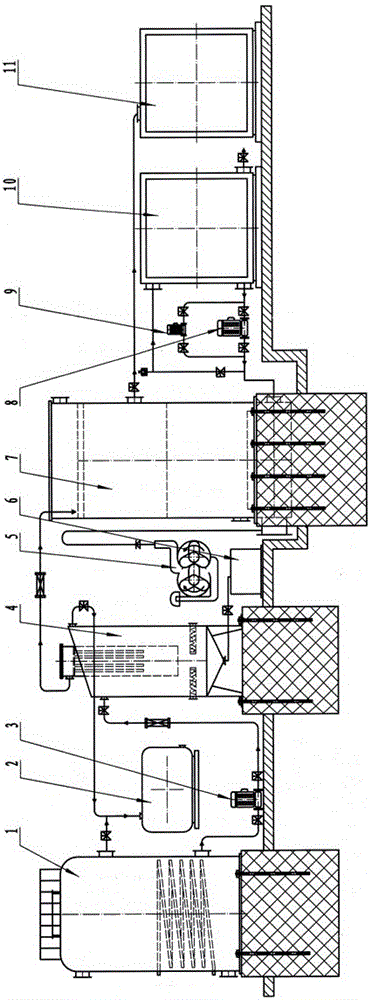

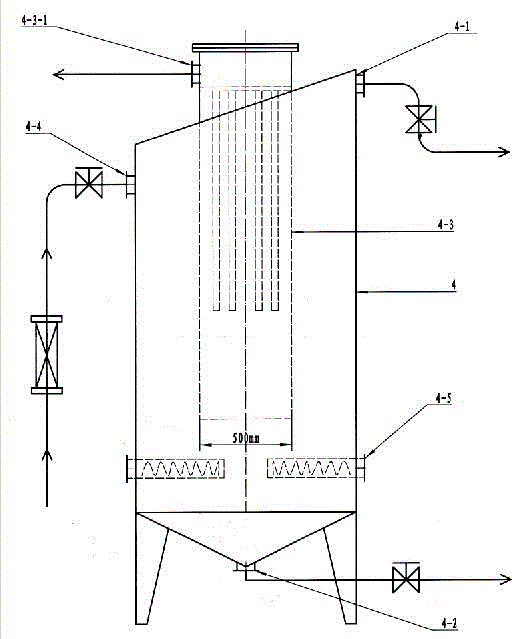

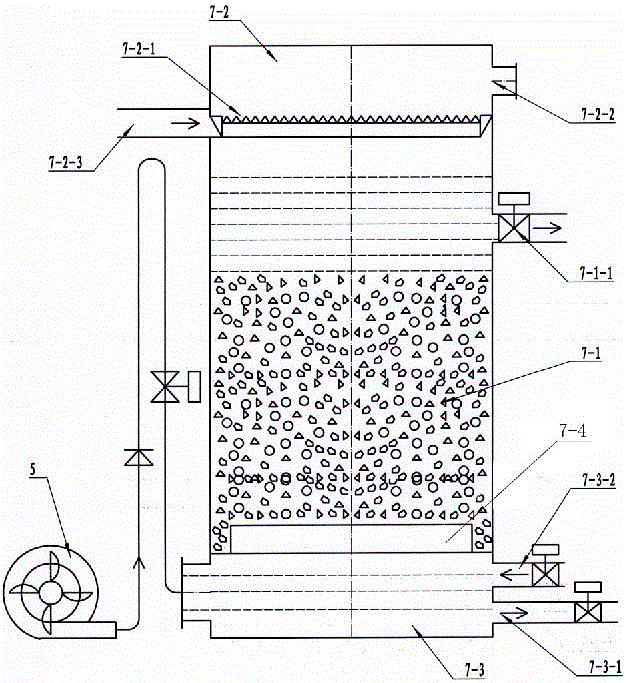

[0027] The methods for treating oil production sewage are gravity method for oil production sewage treatment process. The oil production sewage is transported by the tank truck to the external thermal insulation single well tank of the water treatment station, and the oil production sewage is pumped in a tangential form Enter the vertical sand degreasing device 4, the mud and sand will settle in the cone at the bottom, and the mud and sand will be discharged regularly, once every 15-20 days, and the turbid water will enter the PP filter group 4-3, and the impurities above 5um will settle in the lower part Cone body, sewage below 5um naturally flows into the gravity filter device 7, waste oil floats on the angle of the sloping plate of the tank body at 36.6°, and naturally flows into the sludge tank. The sewage in the gravity filter device 7 is driven into the upper water distributor 7-2 on the upper part of the gravity filter device 7 by the operating pump 3, and falls evenly o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com