Plate-type vacuum membrane distillation evaporator and application thereof

A vacuum membrane distillation and evaporator technology, applied in the field of seawater desalination and membrane separation, can solve the problems of difficult cleaning, difficult expansion of membrane modules, and small scale of water production, and achieve the effects of easy cleaning, easy expansion, and increased water production ratio.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] Hereinafter, the present invention will be further described through the accompanying drawings. The following examples are only descriptive, not restrictive, and cannot limit the protection scope of the present invention.

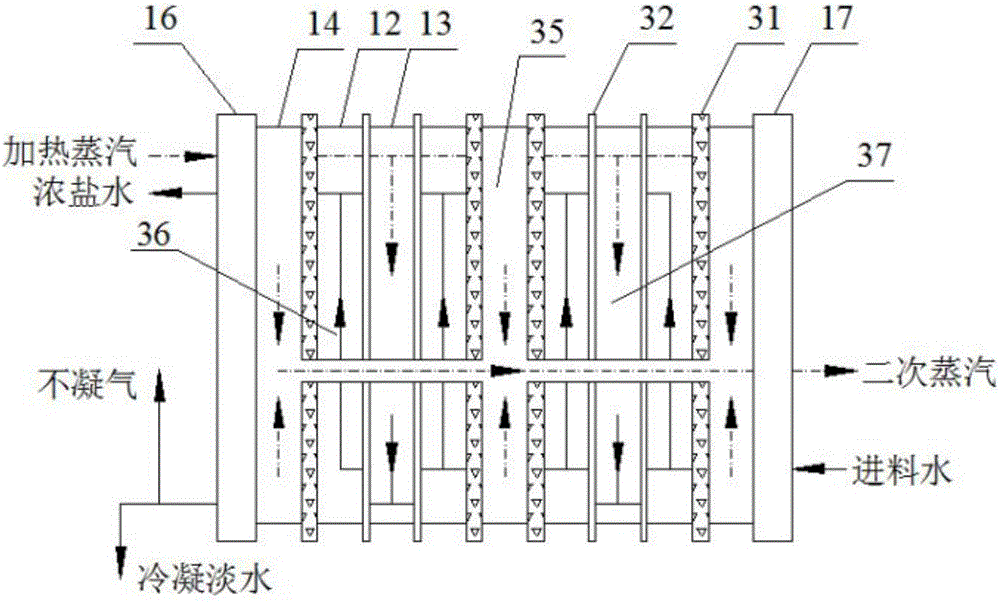

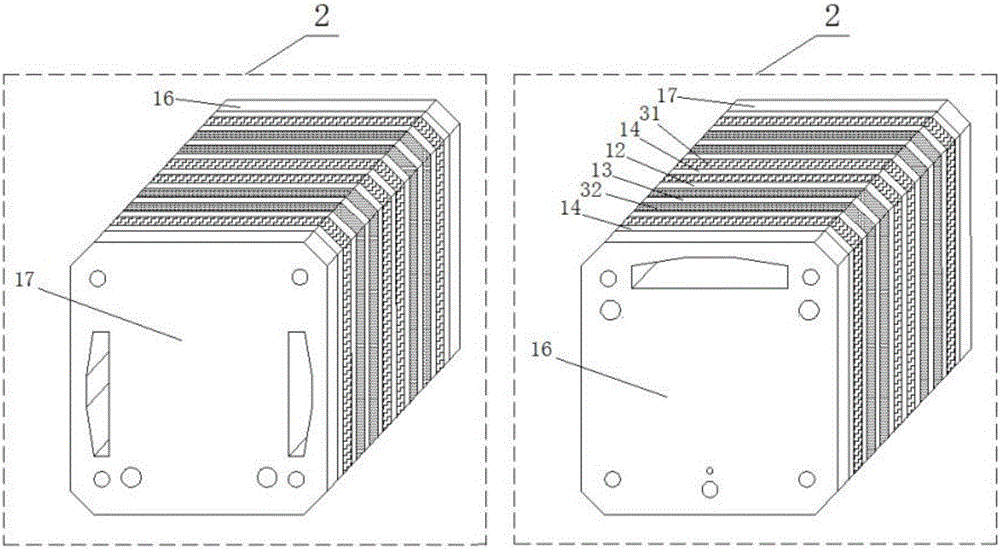

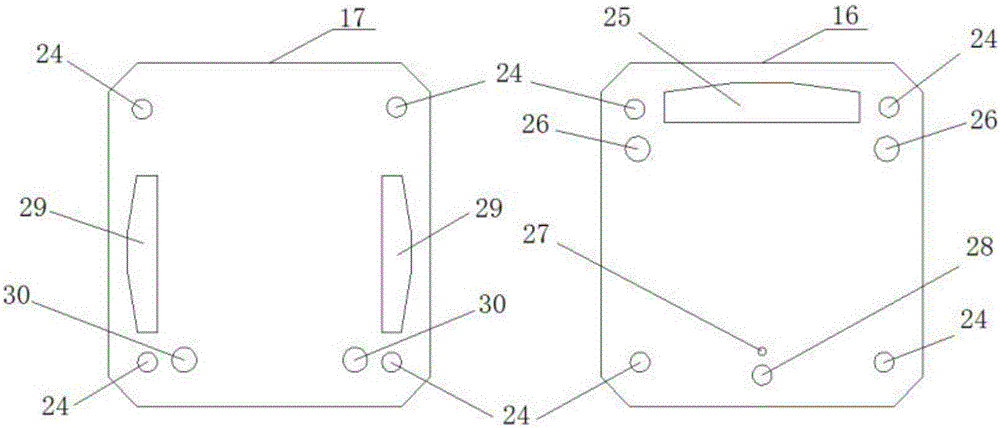

[0034] A plate vacuum film distillation evaporator, such as figure 1 Or as shown in 2, including the steam inlet side end plate 16 on the left side and the steam outlet side end plate 17 on the right side, between the steam inlet side end plate and the steam outlet side end plate, there are two Secondary steam channel sealing ring 14, plate diaphragm frame 31, material liquid channel sealing ring 12, heat exchange plate frame 32, heater steam channel sealing ring 13, heat exchange plate frame 32, material liquid channel sealing ring 12 and plate type Membrane blocks formed by the combination of membrane frame 31, multiple modules are sequentially connected and arranged by secondary steam channel sealing ring 14 to form the core membrane stack of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com