A composite catalyst for degrading organic chlorine pollutants and its preparation method

A composite catalyst and pollutant technology, applied in physical/chemical process catalysts, water pollutants, chemical instruments and methods, etc., can solve the problems of high purity of nano-zero valent iron, high technical equipment requirements, poor agglomeration performance, etc. Low equipment requirements, guaranteed degradation rate, and less agglomeration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0035] 1. Preparation of solution A: Take 30ml of absolute ethanol and add it to a 250ml Erlenmeyer flask, and put the Erlenmeyer flask into a 40°C water bath to heat and stir; slowly add 10ml of butyl titanate to the vigorously stirred Erlenmeyer flask , and then quickly add 3ml of glacial acetic acid and Fe(NO 3 ) 3 , keep stirring at 40°C for 30 minutes to prepare solution A, wherein the mass ratio of Ti to Fe is 0.05;

[0036] 2. Preparation of solution B: Take 10ml of absolute ethanol and 5ml of distilled water in a 50ml small beaker, then add hydrofluoric acid, adjust the pH to 2 with concentrated nitric acid, and make solution B, wherein the molar ratio of Ti to F is 0.01;

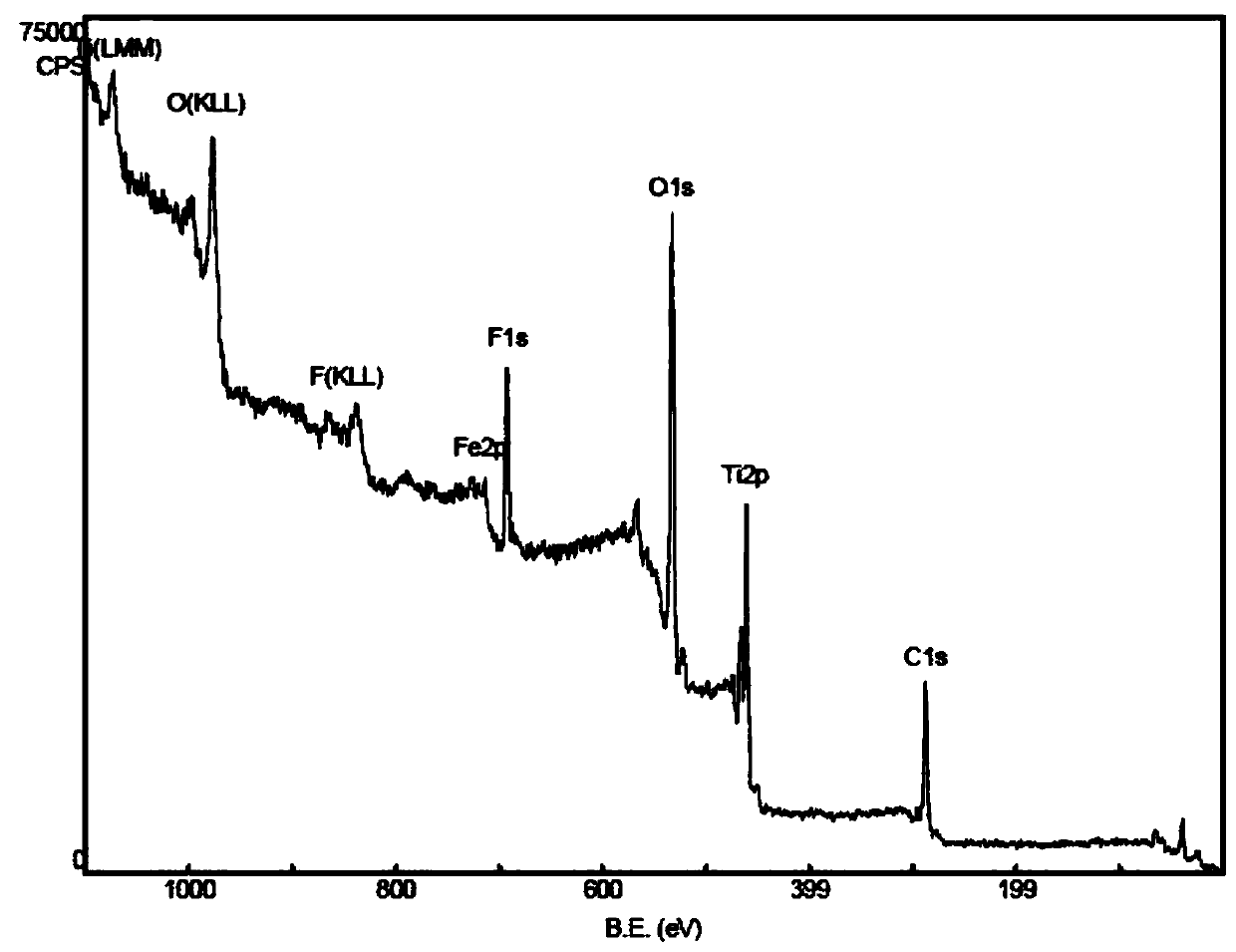

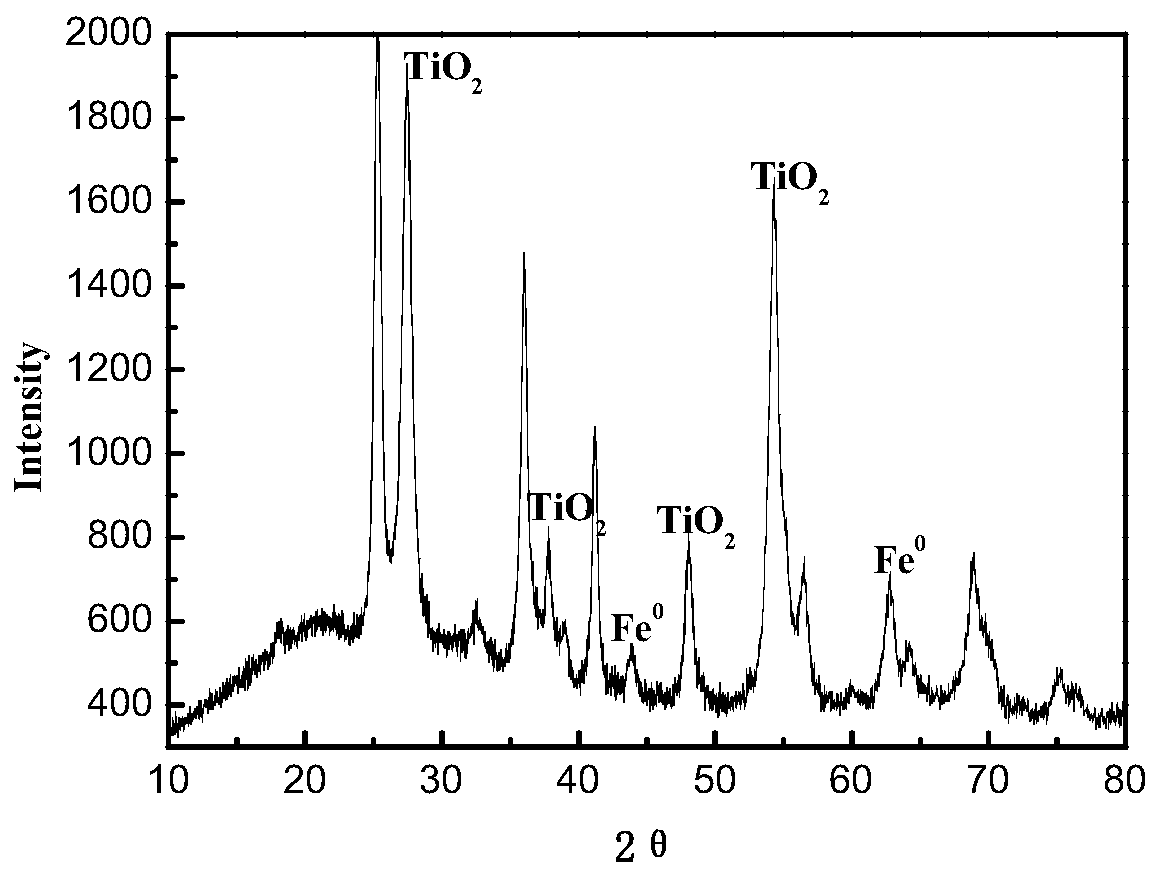

[0037] 3. Fe 3+ / F-TiO 2 Preparation of powder: Add solution B dropwise to solution A with vigorous stirring in a water bath at 40°C, age for 24 hours to obtain a gel, dry in an oven at 80°C, and roast in a vacuum at 100°C for 6 hours to obtain Fe 3+ / F-TiO 2 powder;

[0038] 4. Fe 0 / F-TiO ...

Embodiment 1

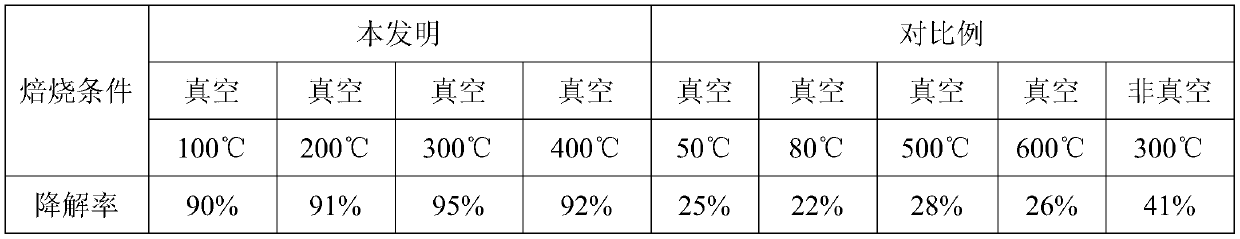

[0041] The influence of embodiment 1 calcining temperature on composite catalyst degradation performance

[0042] The calcination conditions were changed as shown in Table 1, and other steps were the same as the above preparation method, and 2,4,6-trichlorophenol was degraded according to the above method, and the effect of the composite catalyst on the degradation performance of organochlorine pollutants was studied.

[0043] Table 1 Degradation rate of composite catalyst under different calcination conditions

[0044]

[0045] As can be seen from the above table 1, under the vacuum condition limited by the present invention and the temperature of 100~400 DEG C, the degradation rate of the prepared composite catalyst to organic chlorine pollutants reaches more than 90%, but when the roasting conditions are changed, Decreasing or increasing the calcination temperature has a great influence on the degradation performance of the prepared composite catalyst, and its degradatio...

Embodiment 2

[0047] Embodiment 2 The influence of titanium-iron mass ratio on the degradation performance of composite catalyst

[0048] The mass ratio of titanium to iron was changed as shown in Table 2, and the other steps were the same as the above preparation method, and 2,4,6-trichlorophenol was degraded according to the above method, and the effect of the composite catalyst on the degradation performance of organochlorine pollutants was studied.

[0049] Table 2 Degradation rate of composite catalysts prepared with different titanium-iron mass ratios

[0050]

[0051] As can be seen from the above table 2, under the condition of 0.01~0.2 mass ratio of ferro-titanium limited by the present invention, the degradation rate of the prepared composite catalyst to organic chlorine pollutants reaches more than 90%, but when the mass ratio of ferro-titanium is changed When it is reduced, the degradation rate of the composite catalyst prepared by it to organic chlorine pollutants is reduced...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com