A dry method for preparing modified bentonite

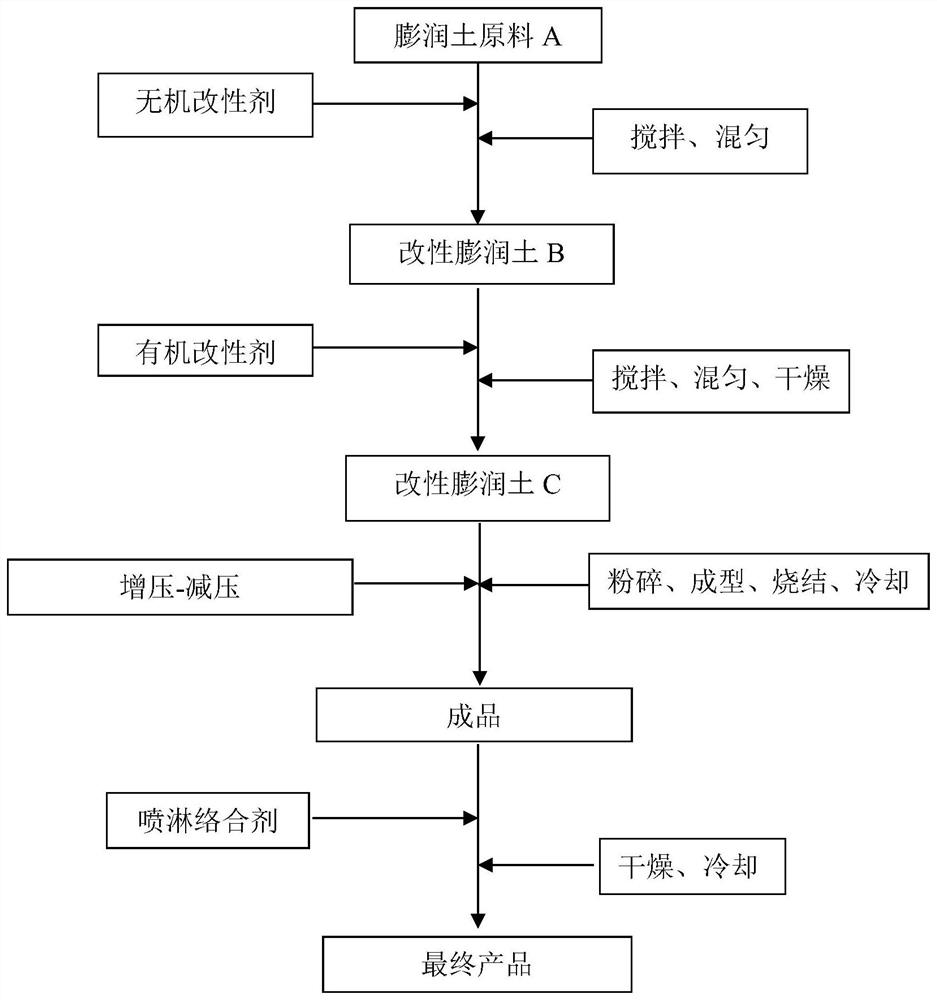

A bentonite and modification technology, applied in the field of dry preparation of modified bentonite, can solve problems such as poor ion adsorption and exchange capacity, and achieve the effects of increasing adsorption capacity and ion exchange capacity, short process flow, and stable material performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

[0028] Step 1: Bentonite raw material preparation. The mined raw materials are simply manually selected, stones, sticks and other mechanical impurities are removed, crushed by jaw crushers and ball mills, with a particle size of 100 mesh to 200 mesh, and bentonite raw material A is obtained.

[0029] Step 2: Inorganic modifier preparation. (1) Sodium-based modifier. Industrial sodium carbonate or sodium bicarbonate is added according to mass percentage wt 0.1% to 10%. (2) aluminum pillar propping agent aluminum chlorohydrate [containing polyaluminium, Al 2 (OH)nCl 6-n ]. According to the mass percentage of 0.1% to 10%. (3) Magnetic material iron ore powder. Iron ore powder (100-200 mesh) with a TFe content of not less than 50% is added at a mass percentage of 0.5% to 10%. (4) Quartz sand (100-200 mesh). The mass percentage is 0.5% to 5%. (5) Zeolite (100-200 mesh). The mass percentage is 0.5% to 5%. (6) Nano photocatalyst TiO 2 (Application patent application numbe...

Embodiment approach 2

[0038] Step 1: Bentonite raw material preparation. The mined raw materials are simply manually selected, stones and other mechanical impurities are removed, crushed by jaw crushers and ball mills, with a particle size of 100 mesh to 200 mesh, and bentonite raw material A is obtained.

[0039] Step 2: Inorganic modifier preparation. (1) Sodium-based modifier. Sodium carbonate + sodium bicarbonate (1:1 ratio), added according to the mass percentage wt 0.1% ~ 10%. (2) Aluminum pillar proppant. Aluminum carbonate + aluminum chloride hydrate (1:2 ratio). According to the mass percentage of 0.1% to 10%. (3) Magnetic material iron ore powder. Add iron ore powder (100-200 mesh) with TFe content not less than 50% according to the mass percentage of 0.5%-10%. (4) Quartz sand (no more than 100 mesh). The mass percentage is 0.5% to 5%. (5) Zeolite (100-200 mesh). The mass percentage is 0.5% to 5%. (6) Nano photocatalyst TiO 2 (Application patent application number is 2009101110...

Embodiment approach 3

[0048] Step 1: Bentonite raw material preparation. The mined raw materials are simply manually selected, stones and other mechanical impurities are removed, crushed by jaw crushers and ball mills, with a particle size of 100 mesh to 200 mesh, and bentonite raw material A is obtained.

[0049] Step 2: Inorganic modifier preparation. (1) Sodium-based modifier. The industrial sodium-based modifier sodium carbonate + sodium bicarbonate + sodium sulfate (1:1:1 ratio) is added according to the mass percentage wt of 0.1% to 10%. (2) Aluminum proppant (1:1:1 ratio). According to the mass percentage of 0.1% to 10%. (3) Magnetic material iron ore powder. Add iron ore powder (100-200 mesh) with TFe content not less than 50% according to the mass percentage of 0.5%-10%. (4) Quartz sand (no more than 100 mesh). The mass percentage is 0.5% to 5%. (5) Zeolite (100-200 mesh). The mass percentage is 0.5% to 5%. (6) Nano photocatalyst TiO 2 (Application patent application number is 20...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com