A kind of preparation method of wear-resistant superhydrophobic metal surface

A metal surface, super-hydrophobic technology, used in metal processing equipment, devices for coating liquids on surfaces, special surfaces, etc. Conducive to large-scale application and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

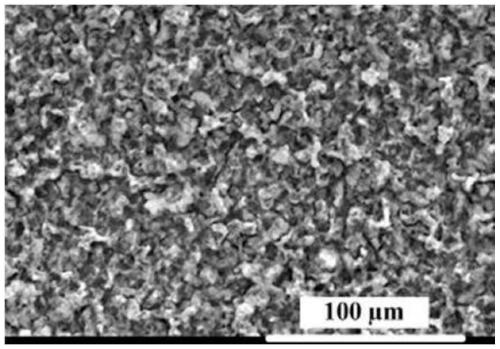

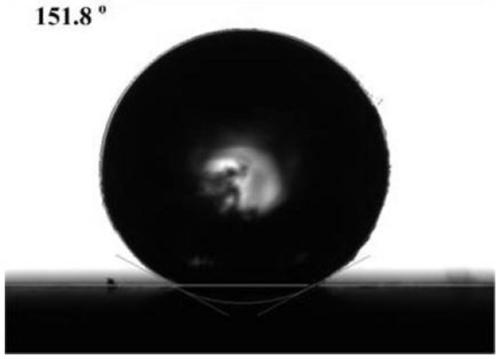

[0031] The preparation method of the wear-resistant superhydrophobic metal surface of the present invention is specifically implemented according to the following steps:

[0032] Step 1, preparing an ordered microstructure array on the surface of the metal substrate by mask micro-electrolytic machining;

[0033] The specific process is:

[0034] Step 1.1, metal substrate treatment: Polish the surface of the metal substrate with sandpaper to make the metal substrate roughness Ra≤0.3, then wash it with acetone, alcohol and deionized water in sequence, dry it with nitrogen, and then dry it for use;

[0035] Step 1.2, preparation of a patterned flexible insulating masking film: the flexible insulating film is made of a polyimide film with a thickness of 0.05-0.2 mm, and the flexible insulating film is first cleaned with alcohol and deionized water and dried with compressed air; using an ultraviolet laser The marking machine processes micro-hole arrays on the flexible insulating f...

Embodiment 1

[0054] Step 1, preparing an ordered microstructure array on the surface of the metal substrate by mask micro-electrolytic machining;

[0055] The specific process is:

[0056] Step 1.1, metal substrate treatment: Polish the surface of the metal substrate with sandpaper to make the metal substrate roughness Ra≤0.3, then wash it with acetone, alcohol and deionized water in sequence, dry it with nitrogen, and then dry it for use;

[0057] Step 1.2, preparation of a patterned flexible insulating masking film: the flexible insulating film is made of a polyimide film with a thickness of 0.05 mm, and the flexible insulating film is first cleaned with alcohol and deionized water and dried with compressed air; marking with an ultraviolet laser The machine processes the micro-hole array on the flexible insulating film, the process parameters: speed: 10mm / s, laser effective power: 3W, frequency: 20KHz;

[0058] Step 1.3, mask micro-electrolytic machining to prepare an ordered microstruc...

Embodiment 2

[0064] Step 1, preparing an ordered microstructure array on the surface of the metal substrate by mask micro-electrolytic machining;

[0065] The specific process is:

[0066] Step 1.1, metal substrate treatment: Polish the surface of the metal substrate with sandpaper to make the metal substrate roughness Ra≤0.3, then wash it with acetone, alcohol and deionized water in sequence, dry it with nitrogen, and then dry it for use;

[0067] Step 1.2, preparation of a patterned flexible insulating masking film: the flexible insulating film is made of a polyimide film with a thickness of 0.1 mm, and the flexible insulating film is first cleaned with alcohol and deionized water and dried with compressed air; marking with an ultraviolet laser The machine processes the micro-hole array on the flexible insulating film, the process parameters: speed: 20mm / s, laser effective power: 2W, frequency: 20KHz;

[0068] Step 1.3, mask micro-electrolytic machining to prepare an ordered microstruct...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com