A method for preparing hollow indium sulfide microspheres at atmospheric pressure and low temperature without template

A template-free, indium sulfide technology, applied in chemical instruments and methods, inorganic chemistry, gallium/indium/thallium compounds, etc., can solve the problems of volatile carbon disulfide, cytotoxicity, and less one-time preparation, and achieve easy Separation and cleaning, controllable size and wall thickness, uniform shape results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

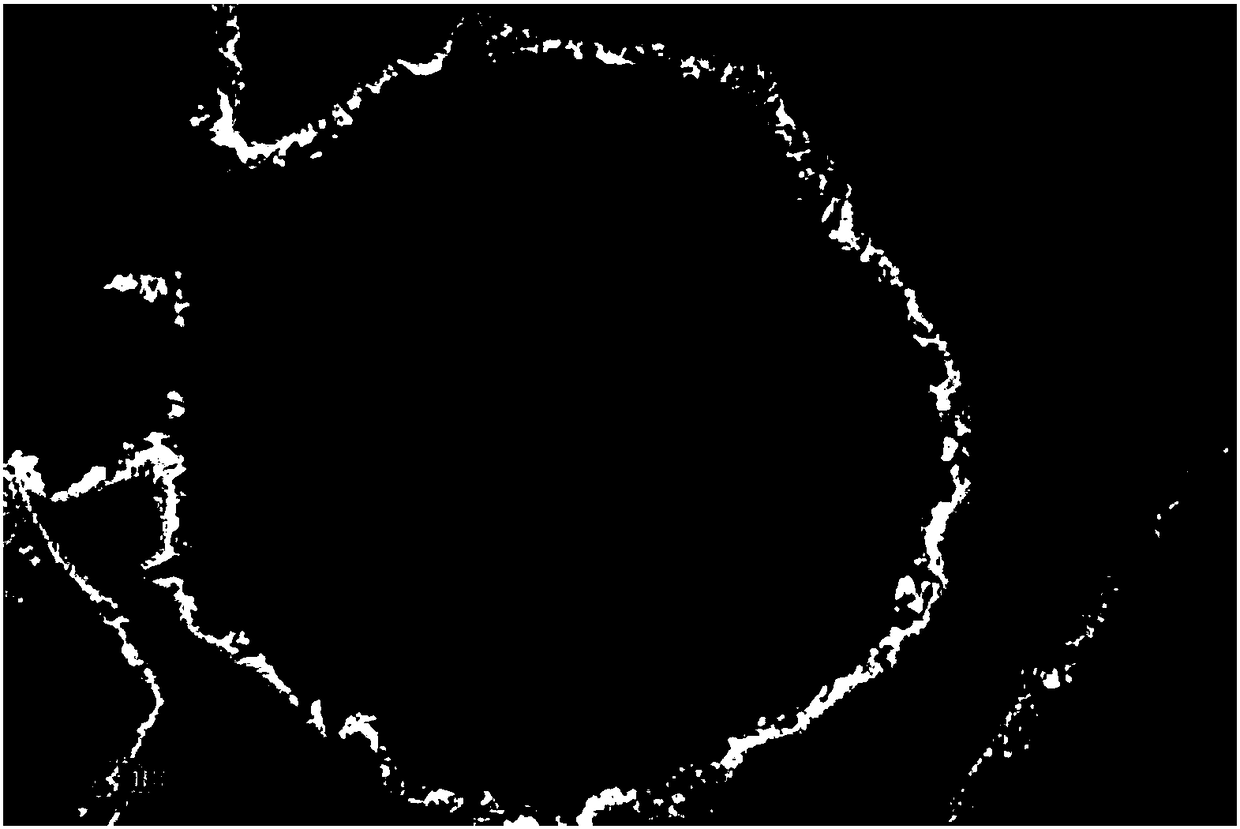

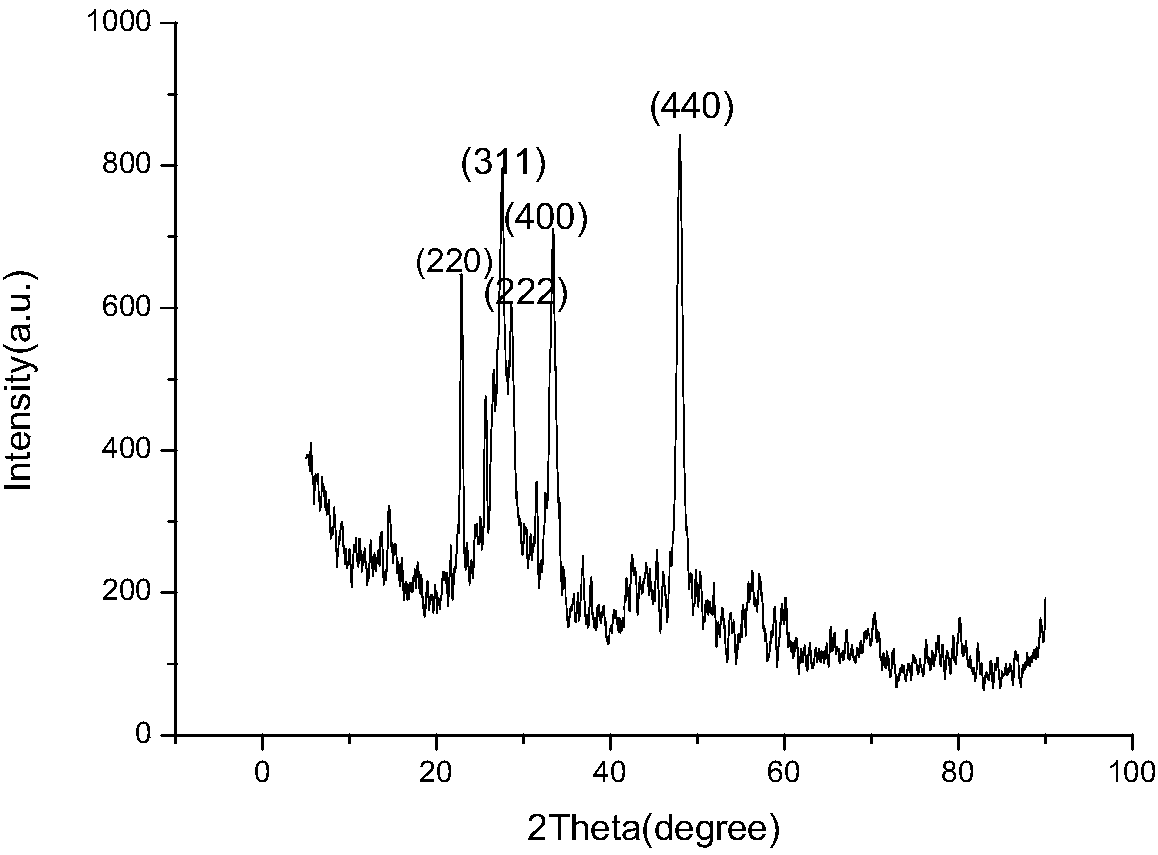

[0029] Mix 50mL 0.004mol / L indium nitrate aqueous solution with 50mL 0.004mol / L 2-methyl-thiopropionamide aqueous solution, then add 1mol / L hydrochloric acid aqueous solution to adjust the pH value to 2.2, microwave heating reaction at 90°C for 15min, statically Place, remove the supernatant, centrifuge, wash, and freeze-dry to obtain the product. The product had a wall thickness of 80 nm and a diameter of ~900 nm. The SEM picture, TEM picture and XRD picture of the product are shown in the appendix figure 1 , 2 and 3.

Embodiment 2

[0031] Mix 50mL 0.004mol / L indium nitrate aqueous solution with 50mL 0.004mol / L 2-p-phenylmethylthioacetamide aqueous solution, then add 0.5mol / L hydrochloric acid aqueous solution to adjust the pH value to 2.5, and then heat it with microwave at 80℃ for 25min. , stand still, remove the supernatant, centrifuge, wash, and freeze-dry to obtain the product. The product has a wall thickness of 70 nm and a diameter of ~800 nm.

Embodiment 3

[0033] Mix 50mL of 0.008mol / L indium chloride aqueous solution with 50mL of 0.024mol / L 2-methyl-thiopropionamide aqueous solution, then add 1mol / L hydrochloric acid aqueous solution to adjust the pH value to 2.2, and react with microwave at 90°C for 15min, Stand still, remove the supernatant, centrifuge, wash, and freeze-dry to obtain the product. The product had a wall thickness of 70 nm and a diameter of ~900 nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com