Preparation method of high-purity anhydrous manganese chloride

An anhydrous manganese chloride and manganese chloride technology, applied in manganese halide and other directions, can solve the problems of uneven heat distribution, high local temperature, uneven heat distribution of materials, etc., and achieve the effect of simple operation and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

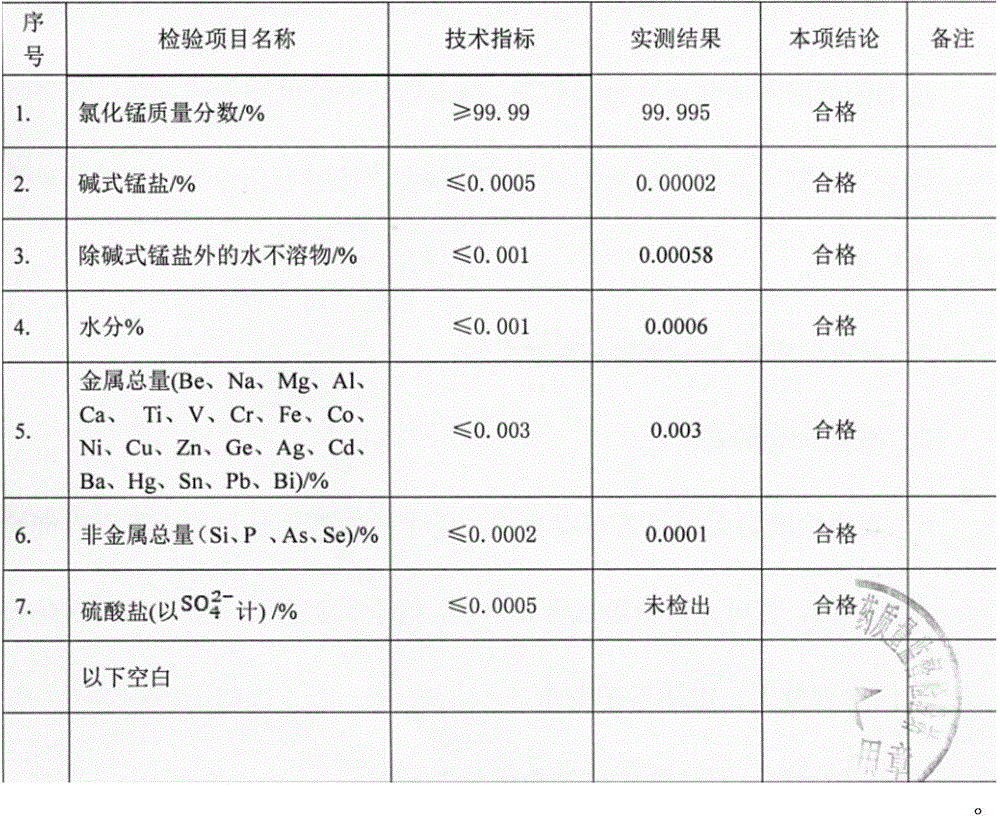

Image

Examples

Embodiment 1

[0043] (1) Manganese powder and hydrochloric acid react to generate manganese chloride solution

[0044] Add a certain amount of water and metal manganese powder (purity 99.4%, a small amount of impurities are mainly carbon, sulfur, phosphorus, silicon, iron and nickel, lead, etc.) in the reactor, stir and disperse, add hydrochloric acid (from pure Water absorbs hydrogen chloride gas preparation), until the manganese powder is completely dissolved, and the excess acid is mixed with a small amount of MnCO 3 Neutralization, the reaction releases a large amount of heat, cooled with water, the reaction produces a large amount of hydrogen and a small amount of HCl, water vapor (due to the higher reaction temperature), H 2 S.PH 3 Gases such as HCl and water vapor are condensed to the reactor through the condenser installed on the upper part of the reactor to continue to react with manganese powder, H 2 S.PH 3 Absorbed by the absorption device, the hydrogen is vented;

[0045] (2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| purity | aaaaa | aaaaa |

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com