Microporous overcurrent ozone catalytic ceramic membrane for waste water deep treatment as well as preparation method and application method thereof

An ozone catalysis and advanced treatment technology, applied in water treatment parameter control, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the problems of catalyst mass transfer efficiency or low effective catalytic area, etc. Improve catalytic efficiency and ensure the effect of advanced treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

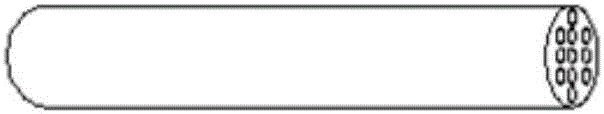

[0039] A kind of preparation method of the microporous overflow ozone catalytic ceramic membrane used for the advanced treatment of waste water of the present invention, by preparing the forming aid containing hydroxypropyl methylcellulose, polyethylene glycol and dysprosium nitrate, molybdenum nitrate, manganese nitrate solution, and with sintered Al 2 o 3 Powder mixing for vacuum sliming, through Al 2 o 3 The adsorption of the powder loads the active ingredients on the carrier to form a flow-through ceramic membrane with well-developed through-holes, so that in practical application, the waste water can be forced to flow through the micropores inside the catalyst to strengthen the mass transfer between the waste water and the surface of the catalyst. At the same time, the effective catalytic area is significantly increased, thereby improving the catalytic efficiency of the catalyst. The concrete steps of the preparation method of the microporous overflow ozone catalytic c...

Embodiment 1

[0051] Will Al 2 o 3 The powder is calcined at 1400°C for 8 hours to convert all of it into α-Al 2 o 3 , so as to control the volume shrinkage and expansion during the sintering process, reduce the cracking during the sintering process, and improve the sintering yield; the pre-fired Al 2 o 3 The powder is ground into a uniform powder of about 400 mesh for later use. Preparation of hydroxypropyl methylcellulose, polyethylene glycol and dysprosium nitrate, molybdenum nitrate, manganese nitrate forming aids and catalytic component loading solution, wherein the concentration of hydroxypropyl methylcellulose is 5%, the concentration of polyethylene glycol is 10 %, the concentrations of dysprosium nitrate, molybdenum nitrate and manganese nitrate are 50% respectively; Al 2 o 3 The powder is mixed with 5% mass ratio of forming aid solution, and enters the vacuum mud refining machine. After 3 hours of mud refining, it is processed into a plate type, tube type or honeycomb cataly...

Embodiment 2

[0054] Will Al 2 o 3 The powder is calcined at 1400°C for 8 hours to convert all of it into α-Al 2 o 3 , so as to control the volume shrinkage and expansion during the sintering process, reduce the cracking during the sintering process, and improve the sintering yield; the pre-fired Al 2 o 3 The powder is ground into a uniform powder of about 600 mesh for later use. Preparation of hydroxypropyl methylcellulose, polyethylene glycol and dysprosium nitrate, molybdenum nitrate, manganese nitrate forming aids and catalytic component loading solution, wherein the concentration of hydroxypropyl methylcellulose is 10%, and the concentration of polyethylene glycol is 15% %, dysprosium nitrate, molybdenum nitrate, and manganese nitrate are respectively 40%; Al 2 o 3 The powder is mixed with a 6% mass ratio of forming aid solution, and enters the vacuum mud refining machine. After 3 hours of mud refining, the vacuum extruder is used to process it into a tubular catalytic filter mem...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com