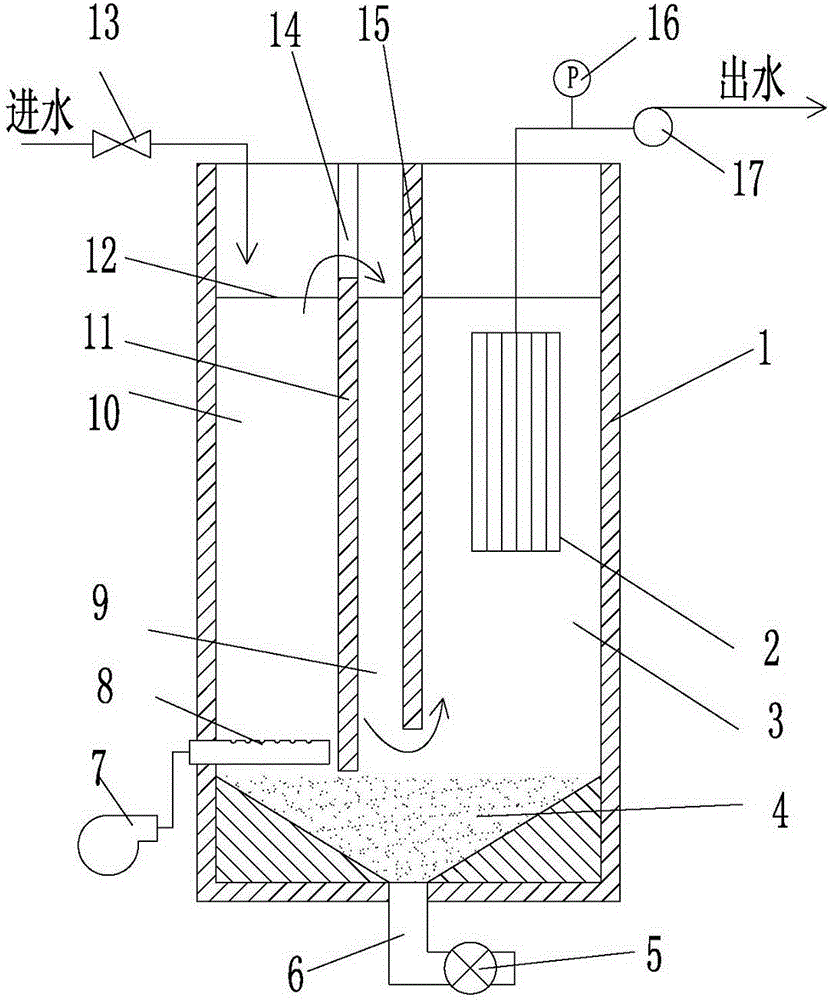

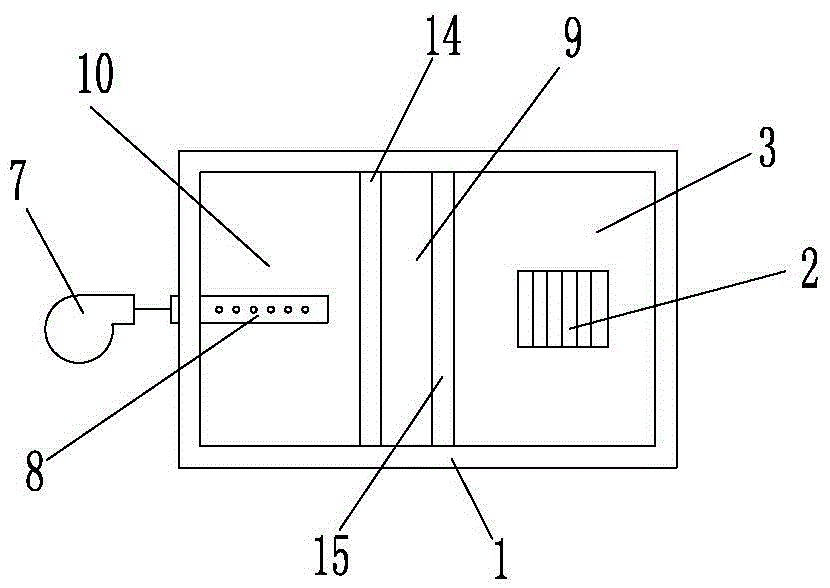

Aerobic-anoxic integration AO membrane bioreactor

A membrane bioreactor, an integrated technology, applied in the direction of aerobic and anaerobic process treatment, food industry wastewater treatment, etc., can solve the problems of large floor area, complicated operation, high operating cost, etc., and achieve small floor space, Simplify the process and achieve good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 1

[0016] Implementation Case 1: Apply the process of the present invention to treat potato starch production wastewater. In this implementation case, the main operating parameters of the integrated AO membrane bioreactor are: the concentration of the mixed liquid suspended sludge is 3000~4000mg / L, the hydraulic retention time is 8h, the sludge age is 30~40d, and the dissolved sludge in the reactor The oxygen concentration is 4~6mg / L. The influent of the biochemical reactor is pretreated potato starch production wastewater, the main water quality indicators: COD concentration is 700~1500mg / L, pH is 7.5~8.5, TN (total nitrogen concentration) is 180~200mg / L, TP (total phosphorus concentration) is 16.8~19.4mg / L. Technological conditions: The whole system is in the state of continuous water inlet and outlet, and the volume load is 1.2-1.5kgBOD5 / (m 3 . d), the treated water volume is 5~8m 3 , covers an area of 2m 2 . The water quality indicators after treatment are: COD 60~80m...

Embodiment example 2

[0017] Implementation Case 2: Applying the process of the present invention to treat astaxanthin production wastewater. In this implementation case, the main operating parameters of the integrated AO membrane bioreactor: the concentration of suspended sludge in the mixed liquid is 6000mg / L, the hydraulic retention time is 6h, the sludge retention time is 30d, and the dissolved oxygen concentration in the reactor is 4 ~6mg / L. The influent of the biochemical reactor is the pretreated astaxanthin production wastewater. The main water quality indicators are: the COD concentration is 1700~2000mg / L, the pH value is about 6.5~7.5, and the TN concentration is 200~250mg / L. The concentration of TP is 18.2~24.7mg / L. Technological conditions: The whole system is in the state of continuous water inlet and outlet, and the volume load is 0.8-1.0kgBOD5 / (m 3 d), the treatment water volume is 30~50m 3 / d, covers an area of about 20m 2 . The effluent quality indicators after treatment are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com