Site emergency deep treatment device and technology for oil-containing emulsifying liquid wastewater

A technology for advanced treatment and emulsification, which is applied in multi-stage water treatment, water/sewage treatment, water/sewage multi-stage treatment, etc. It can solve the problems of low treatment efficiency, slow reaction speed and high treatment cost, and achieve high treatment efficiency. , the effect of fast response and low processing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

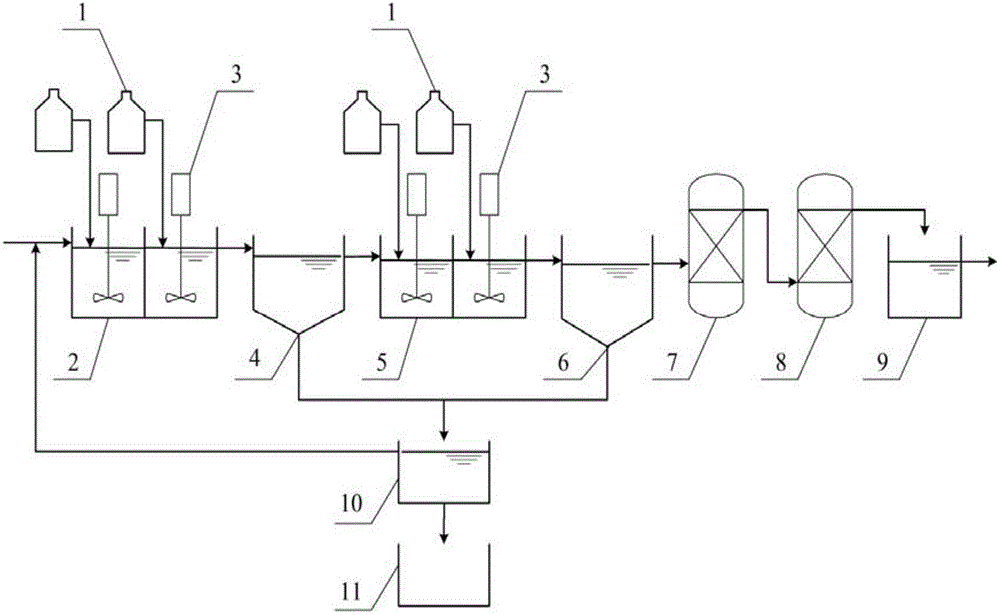

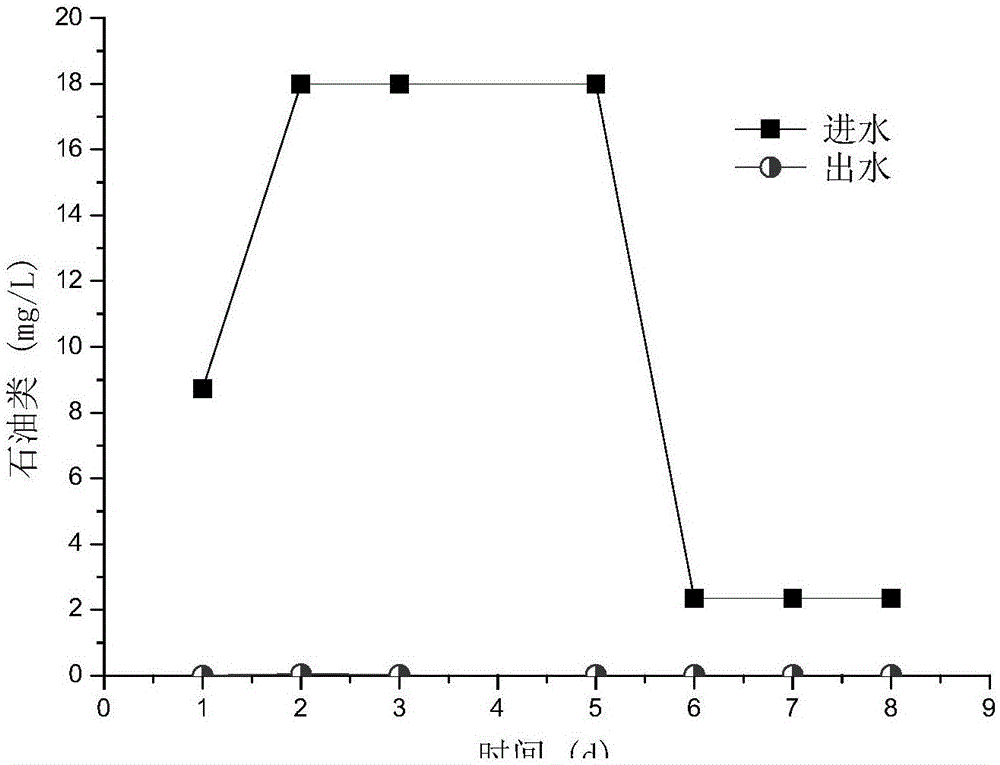

[0049] The on-site emergency advanced treatment device for oily emulsion wastewater is used to treat a certain emulsion wastewater. The disposal scale is 500 cubic meters per day. The quality of the wastewater is shown in the table below. After treatment, it meets the "Environmental Quality Standard for Surface Water" (GB3838-2002) Class III standard limits.

[0050] Table 1 Wastewater Water Quality Status (mg / L)

[0051] index COD Cr

Petro anionic surfactant Volatile phenol Influent concentration 73-216 2-18 0.17 0.25 Emission Standards 20 0.05 0.2 0.005

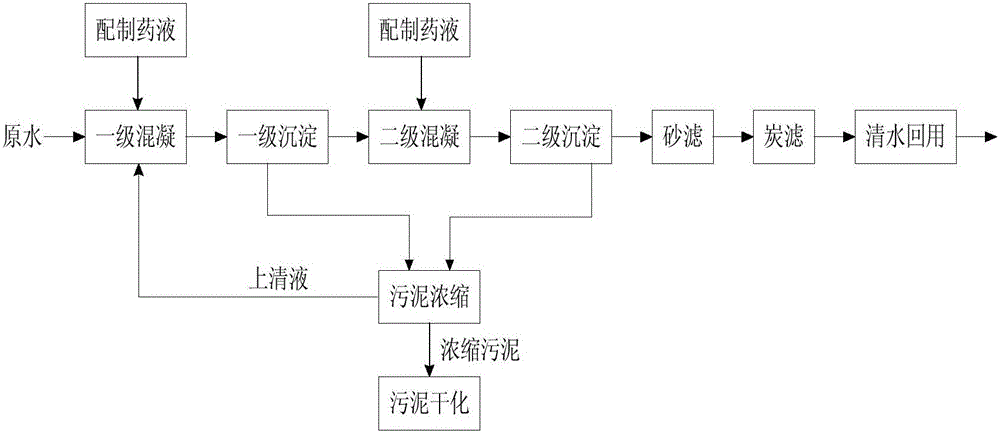

[0052]Adopting the process described in the present invention, firstly carry out demulsification and primary coagulation and sedimentation treatment on wastewater containing emulsion, then continue to add coagulant for secondary coagulation reaction, then separate sludge from water, precipitate and filter The clear liquid enters the sand filter and carbon filter for further treat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com