Nitrate nitrogen chemical separation-physical transfer-based deep denitrification process for sewage

A technology for biological denitrification and sewage, applied in biological water/sewage treatment, ion-exchange water/sewage treatment, water/sewage treatment, etc., can solve the problems of large area, high nitrate nitrogen content in effluent, and high infrastructure cost , to achieve the effect of deep denitrification, strengthening denitrification effect and improving denitrification efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

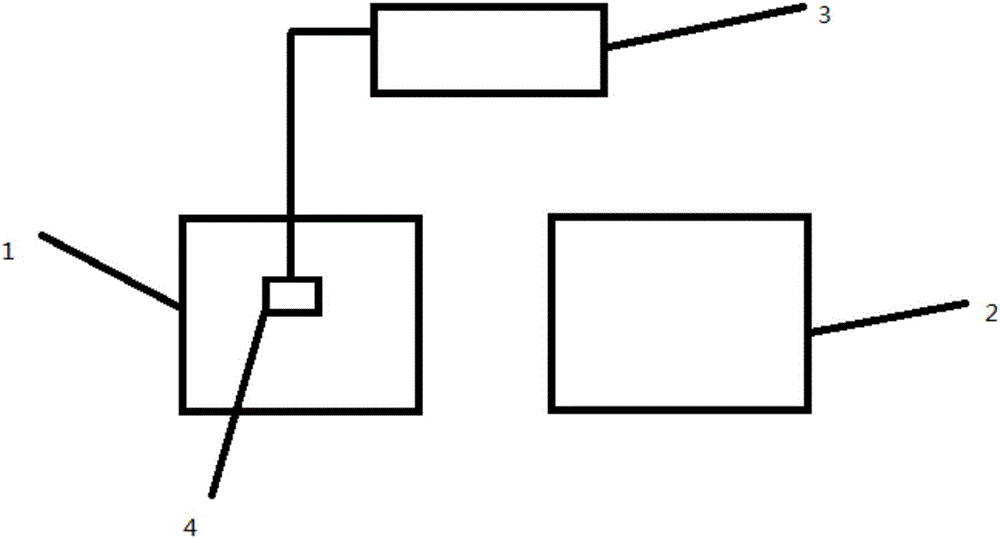

Method used

Image

Examples

Embodiment 1

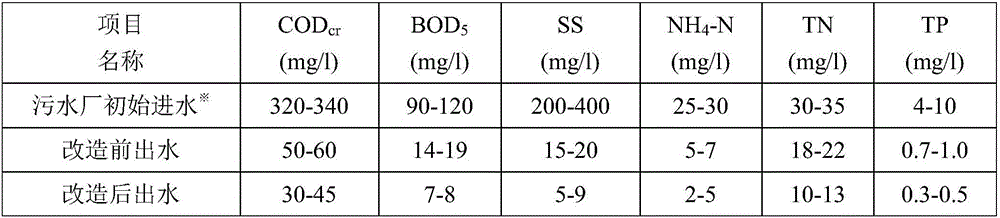

[0039] An urban domestic sewage treatment plant adopts the DE type double-ditch oxidation ditch treatment process, and the effluent implements the first-level (B) standard in GB18918-2002 "Pollutant Discharge Standards for Urban Sewage Treatment Plants". With the development of economy and society, the environmental protection department has increasingly stringent requirements on the effluent treatment of sewage treatment plants. The sewage treatment plant is also facing the task of upgrading, and the effluent must meet the requirements of the "Pollutant Discharge Standards for Urban Sewage Treatment Plants" GB18918-2002 Class A Standard. The main difficulty lies in the further removal of total nitrogen. However, the land around the sewage treatment plant has basically been developed, and there is no condition to provide enough space for the upgrading of the sewage treatment plant. Therefore adopt technological scheme described in the present invention to transform sewage pla...

Embodiment 2

[0052] A rural domestic sewage treatment plant adopts A2 / O treatment process. As the total nitrogen content in the influent has increased to 45-50mg / L in recent years, the average total nitrogen in the treated effluent is 20mg / L, which cannot meet the discharge standard of 15mg / L. Therefore adopt technological scheme described in the present invention to carry out upgrading.

[0053] The specific process scheme steps are as follows:

[0054] (1) Select a strongly basic anion exchange resin with a nitrate nitrogen adsorption capacity of 155 mg / g. The design scale of the sewage plant is 5000m 3 / d, considering the change of instantaneous flow rate, the design flow rate per hour is 250m 3 / h. During the treatment process, the initial dosage of ion exchange resin is 0.4% (mass percentage) of the treated water, that is, the amount of ion exchange resin required per hour initially is 1000 kg. Add 1000kg of ion exchange resin to the loading unit composed of engineering plastic f...

Embodiment 3

[0064]Due to the increasingly stringent effluent standards of an industrial sewage treatment plant in recent years, the original treatment facilities could not meet the requirements and needed to be upgraded. Among them, it is difficult to solve the problem that the concentration of total nitrogen in the effluent is too high. Before the renovation, the average concentration of total nitrogen in the effluent reached 25.3mg / L, and the highest reached 28.4mg / L. It far exceeds the standard of total nitrogen concentration in the effluent <15mg / L stipulated by the sewage treatment plant. After testing, more than 90% of the total nitrogen is nitrate nitrogen. However, the cost of the traditional transformation method is high and the floor space is large, so the process scheme of the present invention is adopted for upgrading and transformation.

[0065] The specific process scheme steps are as follows:

[0066] (1) Select the denitrification flocculant described in the invention p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com