A kind of colored glass ultrafine crystal anti-glare frosting liquid and frosting method thereof

A colored glass and ultra-microcrystalline technology, applied in the field of chemical processing, can solve the problems of uneven particle size of frosting, poor wear resistance and durability, and low stress resistance, so as to achieve environmental protection, good fastness, and durability. The effect of high stress intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

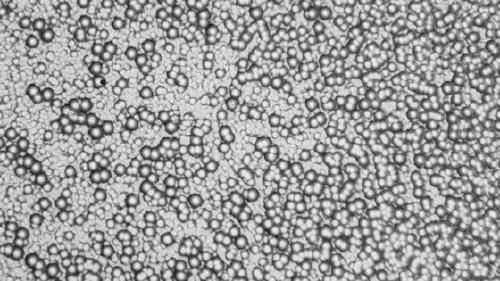

[0033] Take sodium fluoride, potassium fluoride, ammonium sulfate, and potassium sulfate to make A powder in a weight ratio of 8.0:6.0:4.0:1.0, and make B powder with calcium fluoride and barium sulfate in a weight ratio of 5.0:5.0. A powder, B powder and ultrapure water are made into a solution in a weight ratio of 75:10:1000, and the pH is adjusted to 3.0 with sulfuric acid to make a frosting solution. Put the pretreated glass sample into the frosting solution, take it out after frosting for 2.0min under the condition of 25°C magneton speed of 120r / min, wash it with pure water and dry it, measure its roughness Ra and gloss Gs, Taking microscope pictures such as figure 1 .

[0034] Pretreatment steps: glass sample—washing with chromic acid lotion—washing with ultrapure water—drying—applying protective film.

[0035] Such as figure 1 , it was found that the surface of the frosted glass sample was not uniform, and the size gap of ultrafine crystal grains was too large.

...

Embodiment 2

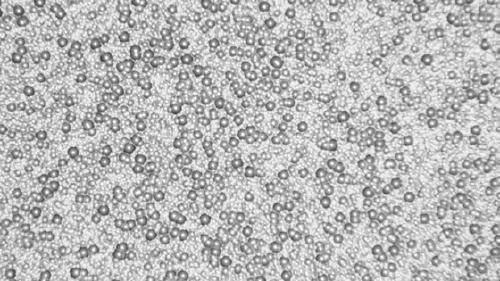

[0046] ① Take sodium fluoride, potassium fluoride, ammonium sulfate, and potassium sulfate to make A powder in a weight ratio of 8.0:5.0:3.0:1.0, and make B powder with calcium fluoride and barium sulfate in a weight ratio of 6.0:5.0. A powder, B powder and ultrapure water are made into a solution at a weight ratio of 75:11:1000, and the pH is adjusted to 3.0 with sulfuric acid to make a frosting solution. Put the pretreated glass sample into the frosting solution, take it out after frosting for 2.0min under the condition of 25°C magneton speed of 120r / min, wash it with pure water and dry it, measure its roughness Ra and gloss Gs, Taking microscope pictures such as figure 2 .

[0047]Roughness index: Ra 1 =0.211μm Ra 2 =0.245μm Ra 3 =0.268μm

[0048] Ra 4 =0.209μm Ra 5 =0.256μm Ra 6 =0.259μm

[0049] Ra 7 =0.299μm

[0050] Ra precision: RSD=0.127

[0051] Gloss index: Gs 1 =20.1GU Gs 2 =25.0GU Gs 3 =28.3GU

[0052] Gs 4 =20.2GU Gs 5 =26.0GU Gs 6 =26.2GU

...

Embodiment 3

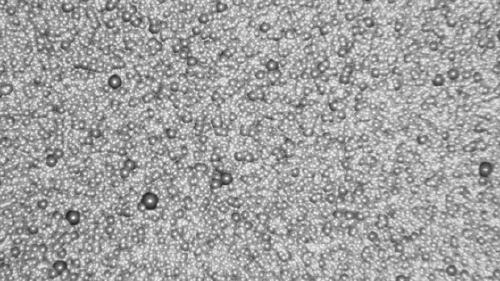

[0066] ① Take sodium fluoride, potassium fluoride, ammonium sulfate, and potassium sulfate in a weight ratio of 8.0:3.0:3.0:1.0 to make A powder, and calcium fluoride and barium sulfate in a weight ratio of 6.0:5.0 to make B powder. A powder, B powder and ultrapure water are made into a solution at a weight ratio of 75:11:1000, and the pH is adjusted to 3.0 with sulfuric acid to make a frosting solution. Put the pretreated glass sample into the frosting solution, take it out after 2.5 minutes of frosting under the condition of 25°C magneton rotation speed 120r / min, wash it with pure water and dry it, measure its roughness Ra and gloss Gs, Taking microscope pictures such as Figure 4 .

[0067] Roughness index: Ra 1 =0.261μm Ra 2 =0.275μm Ra 3 =0.276μm

[0068] Ra 4 =0.266μm Ra 5 =0.268μm Ra 6 =0.273μm

[0069] Ra 7 =0.310μm

[0070] Ra precision: RSD=0.0583

[0071] Gloss index: Gs 1 =22.0GU Gs 2 =21.2GU Gs 3 =18.1GU

[0072] Gs 4 =23.1GU Gs 5 =22.3GU Gs 6 =...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com