Method for preparing light brick by using metallurgical waste slag

A technology for lightweight bricks and adobes, which is applied in the field of preparation of lightweight bricks, can solve the problems of large consumption of land resources and high energy consumption of solid blocks, and achieve the effects of good thermal insulation and sound insulation, and low density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

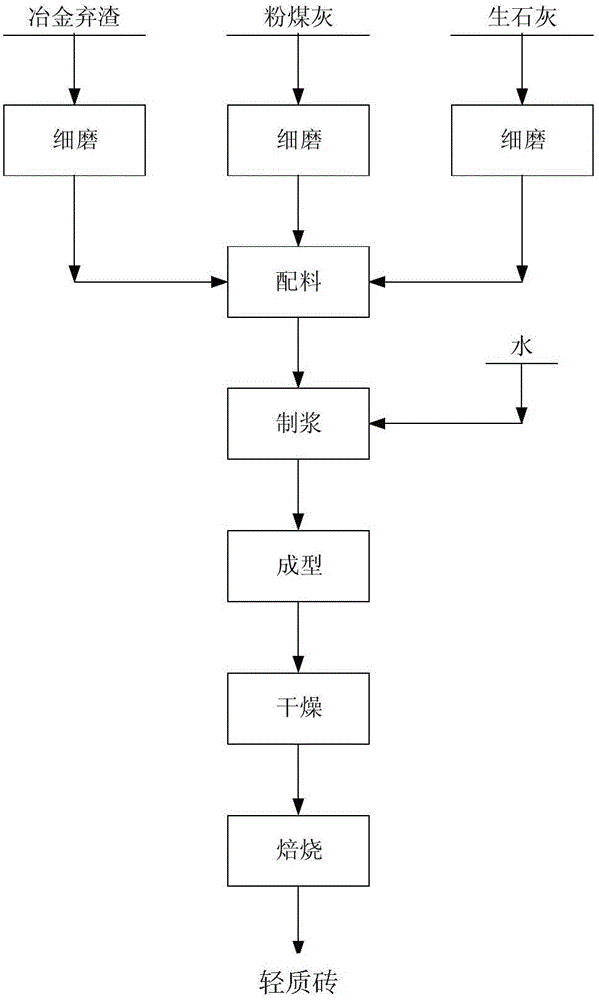

[0029] like figure 1 As shown, 4000kg of red mud (Bayer process red mud) and 2000kg of fly ash and 4000kg of quicklime are dried and then finely ground respectively. %above. After fine grinding, mix the fly ash, quicklime and red mud evenly, add 7000kg of water to the mixed powder and stir, and stir evenly to obtain a slurry, which is transported to a pressure molding machine and under a pressure of 10MPa Pressed into adobe of 200mm*100mm*60mm shape. The adobe is sent to the drying oven through the conveyor belt, the temperature in the drying oven is 120°C, the drying time is 2h, and the water content of the adobe after drying is less than 1%. Send the dried bricks into the roasting furnace for roasting, the roasting temperature is 1000°C, 1150°C, 1100°C, 1200°C, the holding time is 10min, 20min, 30min, 45min respectively, and 4 batches of roasted lightweight bricks are obtained; 4 batches of lightweight bricks that have been roasted are cooled to room temperature to obtain...

Embodiment 2

[0031] like figure 1 As shown, 2000kg of red mud (Bayer process red mud), 1000kg of copper slag, 1000kg of nickel slag, 1000kg of fly ash and 3000kg of quicklime are dried and then finely ground respectively. Those below the order account for more than 90% of the overall quality. After fine grinding, mix the fly ash, quicklime and red mud evenly, add 5600kg of water to the mixed powder and stir, and stir evenly to obtain a slurry, which is transported to a pressure molding machine and under a pressure of 10MPa Pressed into adobe of 200mm*100mm*60mm shape. The adobe is sent to the drying oven through the conveyor belt, the temperature in the drying oven is 120°C, the drying time is 2h, and the water content of the adobe after drying is less than 1%. Send the dried bricks into the roasting furnace for roasting, the roasting temperature is 1000°C, 1150°C, 1100°C, 1200°C, the holding time is 10min, 20min, 30min, 45min respectively, and 4 batches of roasted lightweight bricks are...

Embodiment 3

[0033] like figure 1 As shown, 1000kg of copper slag, 1000kg of fly ash and 3000kg of quicklime are dried and then finely ground. After fine grinding, mix the fly ash, quicklime and red mud evenly, add 3500kg of water to the mixed powder and stir, and stir evenly to obtain a slurry, which is transported to a pressure molding machine and under a pressure of 10MPa Pressed into adobe of 200mm*100mm*60mm shape. The adobe is sent to the drying oven through the conveyor belt, the temperature in the drying oven is 105°C, the drying time is 10h, and the water content of the adobe after drying is less than 1%. Send the dried bricks into the roasting furnace for roasting, the roasting temperature is 1000°C, 1150°C, 1100°C, 1200°C respectively, and the holding time is 10min, 20min, 30min, 45min respectively, and 4 batches of roasted lightweight bricks are obtained; 4 batches of light bricks that have been roasted are cooled to room temperature to obtain finished lightweight bricks; aft...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com