Environmental barrier coating used for poly-carbon and ceramic base compound material and preparation method thereof

A composite material and ceramic-based technology, applied in the field of environmental barrier coating and its preparation, can solve the problems that affect the service life and protection effect of environmental barrier coating, holes and cracks, etc., and achieve excellent oxidation resistance and high phase structure stability Sexuality, the effect of wide application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

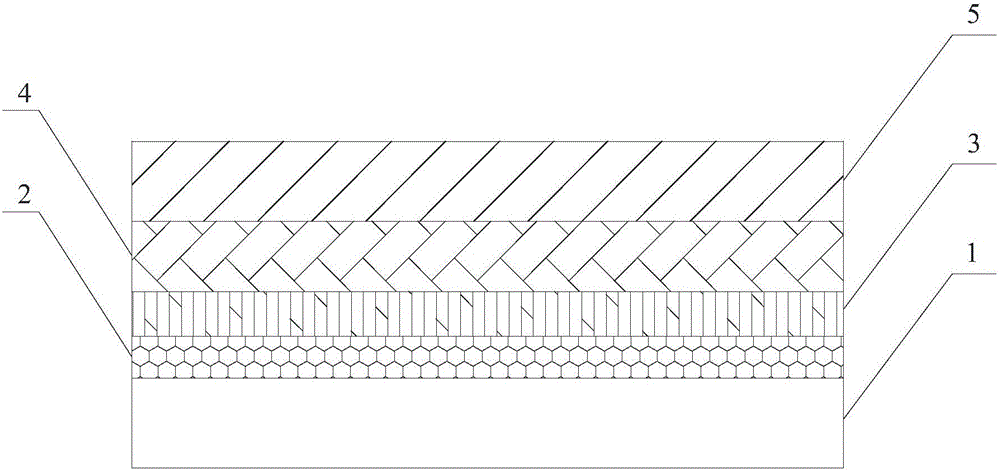

[0023] like figure 1As shown, the embodiment of the present invention provides an environmental barrier coating for multi-component carbon and ceramic matrix composite materials, which includes a silicon bonding layer 2, a mullite layer 3, and a rare earth silicate in sequence from the base material 1 to the outside. Layer 4 and rare earth zirconate layer 5, wherein, the thickness of the silicon bonding layer 2 is 60 μm, the thickness of the mullite layer 3 is 70 μm, the thickness of the rare earth silicate layer 4 is 120 μm, and the thickness of the rare earth zirconate layer 5 The thickness is 120 μm. The material used for the rare earth silicate layer 4 is ytterbium monosilicate, and the material used for the rare earth zirconate layer 5 is lanthanum zirconate.

[0024] The environmental barrier coating for multi-component carbon and ceramic matrix composite materials provided by the embodiment of the present invention includes a silicon bonding layer 2, a mullite layer 3,...

Embodiment 2

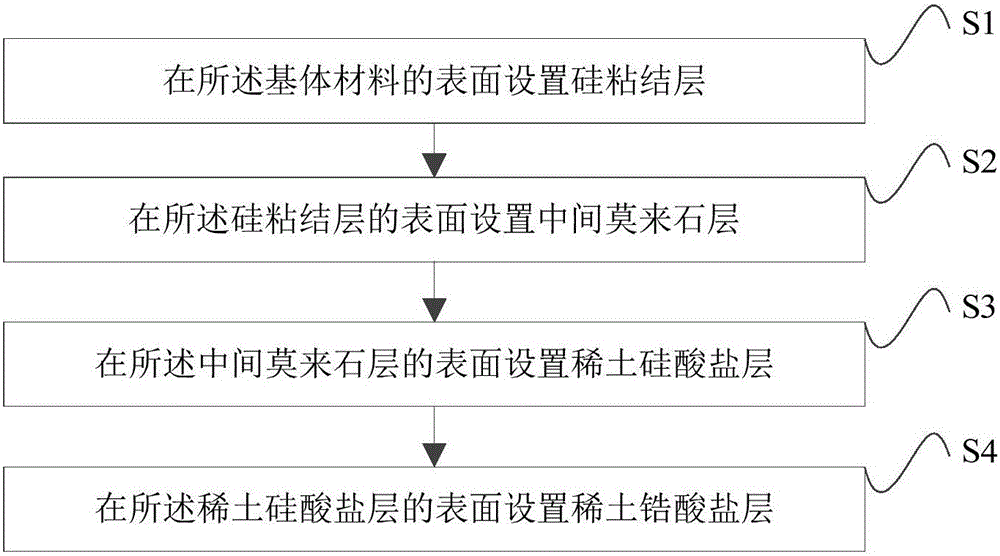

[0052] like figure 1 and figure 2 As shown, the embodiment of the present invention provides a method for preparing an environmental barrier coating for multi-component carbon and ceramic matrix composite materials, comprising: step S1, setting a silicon bonding layer 2 on the surface of the base material 1; step S2, Set mullite layer 3 on the surface of silicon bonding layer 2; step S3, set rare earth silicate layer 4 on the surface of mullite layer 3; Step S4, set rare earth zirconate on the surface of rare earth silicate layer 4 Salt layer 5.

[0053] In the preparation method of the environmental barrier coating for multi-component carbon and ceramic matrix composite materials provided by the embodiment of the present invention, a layer of rare earth zirconate layer is added on the surface of the environmental barrier coating of the traditional rare earth silicate system 5. The rare earth zirconate itself does not contain silicon components, which solves the problem of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com