Preparation method of highland barley grain beta-glucan

A technology of glucan and highland barley, which is applied in the field of preparation of highland barley β-glucan, can solve the problems of inability to obtain high-purity products and low efficiency, and achieve improved extraction efficiency and purity, simple preparation method, and easy operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

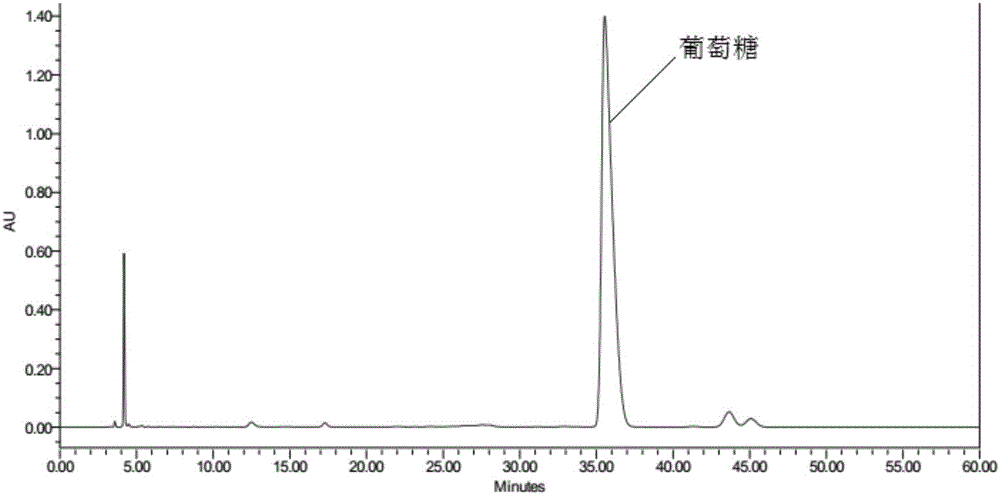

Image

Examples

Embodiment 1

[0014] The preparation method of a kind of highland barley beta-glucan described in this embodiment comprises the following steps:

[0015] Step 1: Peel and crush the highland barley and pass through a 60-mesh sieve to obtain highland barley powder, weigh an appropriate amount of highland barley powder, add 70% ethanol to the highland barley powder according to the ratio of highland barley powder and ethanol to soak, and obtain a soaking solution. Then the soaking solution was centrifuged and dried to obtain a dry powder.

[0016] Step 2, weigh 100g dry powder, add distilled water to the dry powder according to the ratio of dry powder and distilled water as 1:5 and heat to obtain gelatinized liquid, then add α-amylase to the gelatinized liquid, at 95-100 After enzymolysis at ℃ for 30 minutes, the enzymolysis liquid was obtained by cooling.

[0017] Step 3, add concentrated sodium hydroxide solution to the enzymolysis solution obtained in step 2 to obtain a mixed solution with...

Embodiment 2

[0025] The preparation method of a kind of highland barley beta-glucan described in this embodiment comprises the following steps:

[0026] Step 1: Peel and crush the highland barley and pass through a 60-mesh sieve to obtain highland barley powder, weigh an appropriate amount of highland barley powder, add 70% ethanol to the highland barley powder according to the ratio of highland barley powder and ethanol to soak, and obtain a soaking solution. Then the soaking solution was centrifuged and dried to obtain a dry powder.

[0027] Step 2, weigh 100g of dry powder, add distilled water to the dry powder according to the ratio of dry powder and distilled water of 1:10 and heat to obtain a gelatinized liquid, then add α-amylase to the gelatinized liquid, at 95-100 After enzymolysis at ℃ for 40 minutes, the enzymolysis liquid was obtained by cooling.

[0028] Step 3, adding concentrated sodium hydroxide solution to the enzymolysis solution obtained in step 2 to obtain a mixed solu...

Embodiment 3

[0034] The preparation method of a kind of highland barley beta-glucan described in this embodiment comprises the following steps:

[0035] Step 1: Peel and crush the highland barley and pass through a 60-mesh sieve to obtain highland barley powder, weigh an appropriate amount of highland barley powder, add 70% ethanol to the highland barley powder according to the ratio of highland barley powder and ethanol to soak, and obtain a soaking solution. Then the soaking solution was centrifuged and dried to obtain a dry powder.

[0036] Step 2, weigh 100g of dry powder, add distilled water to the dry powder according to the ratio of dry powder and distilled water as 1:7 and heat to obtain gelatinized liquid, then add α-amylase to the gelatinized liquid, at 95-100 After enzymolysis at ℃ for 35 minutes, the enzymolysis solution was obtained by cooling.

[0037] Step 3, add concentrated sodium hydroxide solution to the enzymolysis solution obtained in step 2 to obtain a mixed solution...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Relative molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com