A kind of preparation method of graphene modified polyester film

A graphene modification, polyester film technology, applied in the field of polyester film, achieves the effect of realizing multi-functional composite, good lasting tensile strength and anti-ultraviolet performance, and reducing the phenomenon of powder agglomeration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

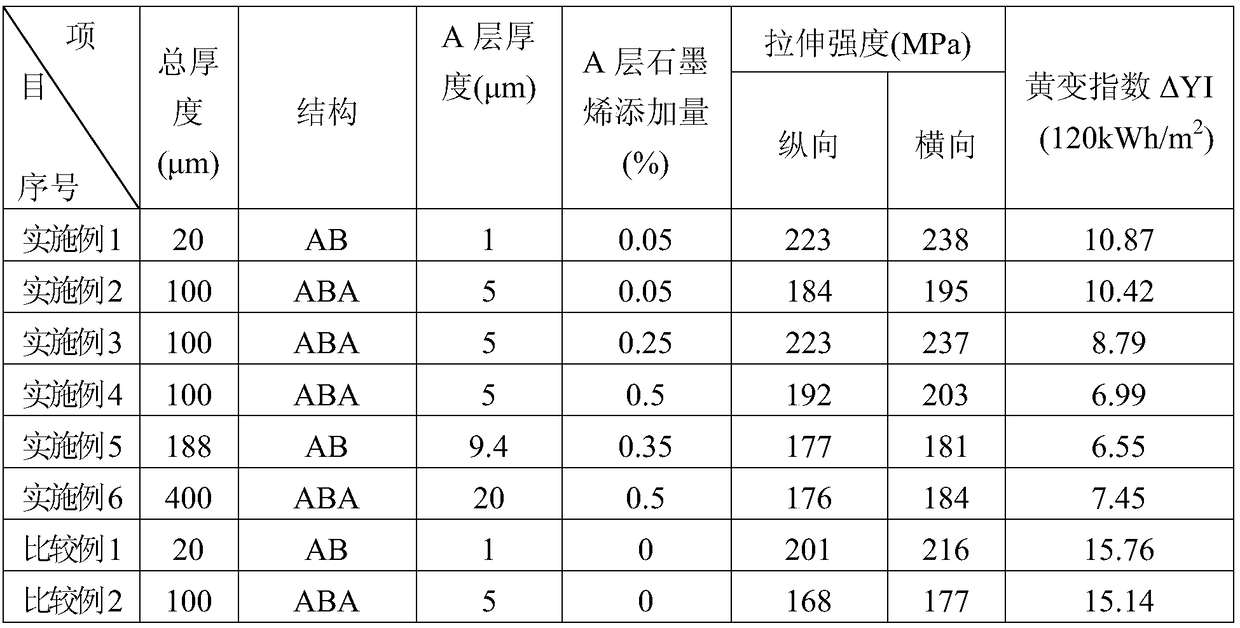

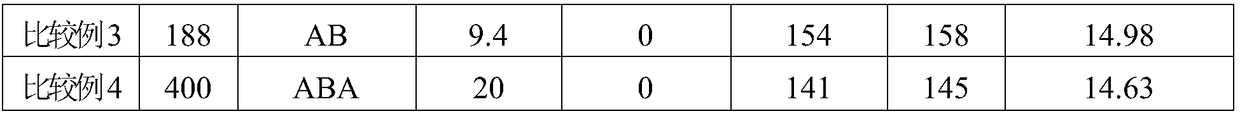

Examples

preparation example Construction

[0020] A method for preparing a graphene-modified polyester film of the present invention comprises the preparation of a graphene dispersion, the synthesis of a graphene-modified polyester, and the processing and molding of a graphene-modified polyester into a film. The specific steps are as follows.

[0021] (1), preparation of graphene dispersion liquid.

[0022] Add 90mL of concentrated sulfuric acid to the reaction bottle placed in the ice-water bath, add a solid mixture of 2g graphite powder and 4g sodium nitrate under stirring, the particle size of graphite powder is less than 30 μm, the content is greater than 95%, and the carbon content is 99.85%. Then add 10g high manganese Potassium acid potassium was added at least three times, and the reaction temperature was controlled not to exceed 20°C. After stirring for 30 minutes, heat the water bath to 35°C, continue stirring for 5 hours, slowly pour 180mL of deionized water, heat the water bath to 98°C, and continue stirring...

Embodiment 1

[0031] A kind of preparation method of graphene modified polyester film of the present invention, concrete steps are as follows.

[0032] (1), preparation of graphene dispersion liquid.

[0033] Put a 250mL reaction bottle in an ice-water bath, add 90mL of concentrated sulfuric acid to the reaction bottle in the ice-water bath, add a solid mixture of 2g graphite powder and 4g sodium nitrate under stirring, the graphite powder particle size is less than 30μm, and the content is greater than 95%. , carbon content 99.85%, then add 10g of potassium permanganate at least three times, the reaction temperature is controlled not to exceed 20°C, after stirring for 30min, heat the water bath to 35°C, continue stirring for 5h, then slowly pour into 180mL of deionized water , heat the water bath to 98°C, continue to stir for 30 minutes, then add hydrogen peroxide, the solution turns bright yellow, when the reaction is complete without gas, filter while it is hot, wash the product with dil...

Embodiment 2

[0042] A kind of preparation method of graphene modified polyester film of the present invention, concrete steps are as follows.

[0043] (1), preparation of graphene dispersion liquid.

[0044] Put a 250mL reaction bottle in an ice-water bath, add 90mL of concentrated sulfuric acid to the reaction bottle in the ice-water bath, add a solid mixture of 2g graphite powder and 4g sodium nitrate under stirring, the graphite powder particle size is less than 30μm, and the content is greater than 95%. , carbon content 99.85%, then add 10g potassium permanganate in four times, the reaction temperature is controlled not to exceed 20°C, after stirring for 30min, heat the water bath to 35°C, continue stirring for 5h, then slowly pour into 180mL deionized water , heat the water bath to 98°C, continue to stir for 30 minutes, then add hydrogen peroxide, the solution turns bright yellow, when the reaction is complete without gas, filter while it is hot, wash the product with dilute hydrochlo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com