A kind of classification method of lignin

A grading method, lignin technology, applied in lignin derivatives, chemical instruments and methods, organic chemistry, etc., can solve lignin physical and chemical properties and processing properties, process obstacles, reduce product application value, uneven structural properties, etc. problem, achieve good thermal stability, increase yield, and high activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] A method for classifying lignin, comprising the steps of:

[0023] S1. Filter the black liquor lignin through a plate-and-frame filter to separate lignin from alkali and inorganic salts to obtain crude lignin feed liquid, and dry to obtain crude lignin.

[0024] S2. Add crude lignin to pure water, pretreat it under the condition of high temperature liquid water at 160°C for 5 minutes, then place the container in cold water at 20°C for rapid cooling for 5 minutes, and use a rotary evaporator for the feed liquid after hydrothermal pretreatment The lignin powder is separated by vacuum distillation, and the lignin is degraded by water preheating, so as to improve the strength of subsequent classification treatment with alcohol-water mixture, improve the quality and yield of lignin, and use cold water to cool quickly to prevent Lignin is exposed to high temperature for a long time and the molecular structure of lignin is destroyed.

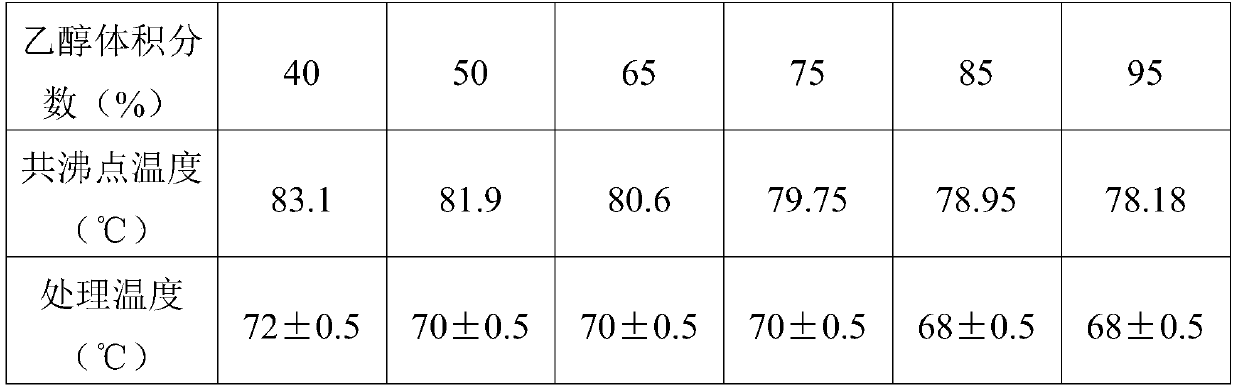

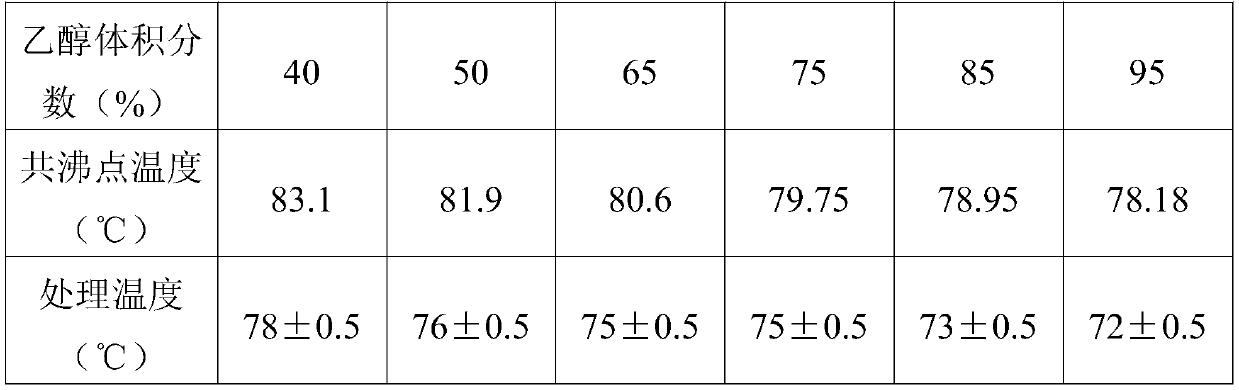

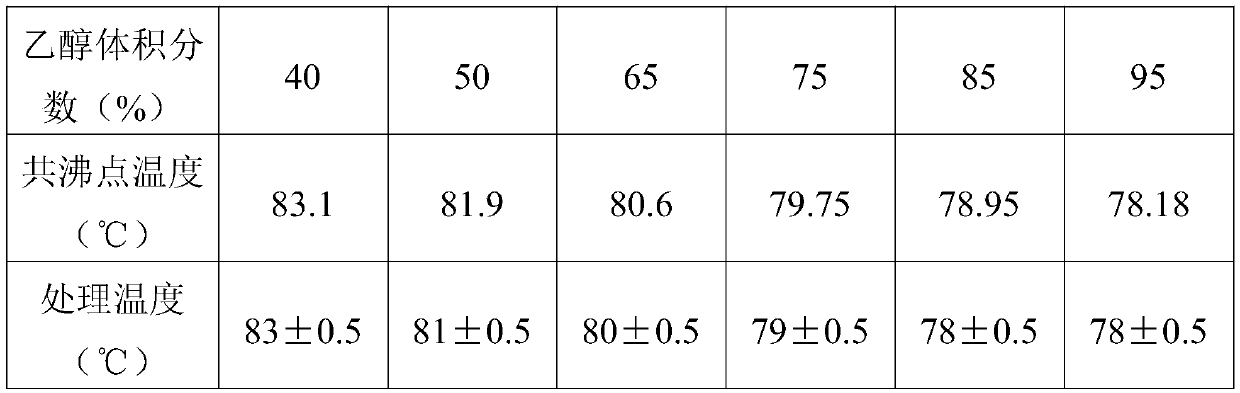

[0025] S3, lignin powder (2g) is dissolv...

Embodiment 2

[0030] A method for classifying lignin, comprising the steps of:

[0031] S1. Filter the black liquor lignin through a filter membrane with a filter hole of 0.1 nanometers to separate the lignin from alkali and inorganic salts to obtain a crude lignin feed solution, and dry to obtain crude lignin.

[0032] S2. Add crude lignin to pure water, pretreat it under high-temperature liquid water conditions at 130°C for 5 minutes, then place the container in cold water at 18°C for rapid cooling for 5 minutes, and use a rotary evaporator for the feed liquid after hydrothermal pretreatment The lignin powder was obtained by distillation and separation under reduced pressure.

[0033] S3, lignin powder (3g) is dissolved respectively in the ethanol aqueous solution of 100ml (volume fraction of ethanol is respectively 40%, 50%, 65%, 75%, 85% and 95% v / v), stirs at different temperatures 5min, let it stand for 18 hours, filter with a G4 sand core funnel, and dry the filter residue (insolu...

Embodiment 3

[0037] A method for classifying lignin, comprising the steps of:

[0038] S1. Filter the black liquor lignin through a filter membrane with a filter hole of 10 nanometers to separate lignin from alkali and inorganic salts to obtain a crude lignin feed solution, and dry to obtain crude lignin.

[0039] S2. Add crude lignin to pure water, pretreat it under high-temperature liquid water at 110°C for 10 minutes, then place the container in cold water at 15°C for rapid cooling for 10 minutes. The lignin powder was obtained by distillation and separation under reduced pressure.

[0040] S3, lignin powder (5g) is dissolved respectively in the ethanol aqueous solution of 100ml (volume fraction of ethanol is respectively 40%, 50%, 65%, 75%, 85% and 95% v / v), stirs at different temperatures 5min, let it stand for 24 hours, filter with a G4 sand core funnel, and dry the filter residue (insoluble lignin) in an oven at 85°C to obtain high molecular weight lignin. The filtrate (soluble lig...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com