Preparation method of crosslinking adhesion bionic coating composed of epoxy-containing phosphorylcholine polymer and dopamine

A technology of epoxy phosphorylcholine and phosphorylcholine, which is applied in the direction of coating, etc., can solve the problems of limited application range, harsh conditions in the synthesis process, and difficulty in preservation, and achieve broad application prospects, simple preparation method, and easy operation convenient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Weigh 16mmol 2-methacryloyloxyethyl phosphorylcholine and 4mmol glycidyl methacrylate, use 0.1mmol azobisisobutyronitrile as initiator, methanol and tetrahydrofuran as solvent, under nitrogen protection, 70 ℃ polymerization reaction for 24 hours, dialyzed after the reaction, and then freeze-dried at -50 ℃ to obtain the epoxy-containing phosphorylcholine polymer.

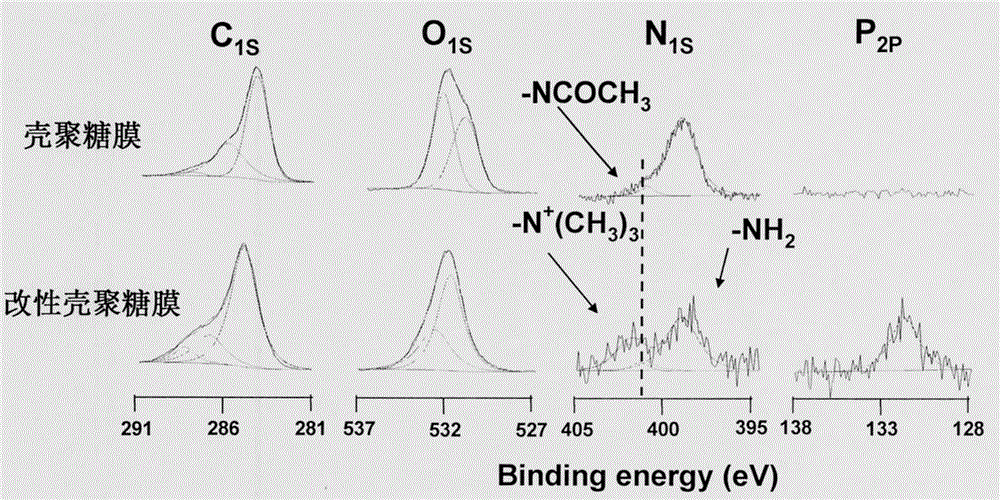

[0028] Using a 400MHz NMR instrument to D 2 O is the hydrogen NMR of the solvent test polymer. There is no peak at 5-7ppm, indicating that there is no residual monomer in the resulting copolymer, and the polymer has been successfully synthesized, with 3.28ppm being -N + (CH 3 ) 3 Characteristic peaks, 0.9-2.2ppm are the peaks of methylene and side chain methyl groups on the main chain to calculate the polymer composition, and it can be known that the polymer composition is basically consistent with the feed ratio.

[0029] The epoxy-containing phosphorylcholine polymer prepared in this example was prepared...

Embodiment 2

[0033] Weigh 14mmol 2-methacryloyloxyethyl phosphorylcholine and 6mmol glycidyl methacrylate, use 0.1mmol azobisisobutyronitrile as initiator, methanol and tetrahydrofuran as solvent, under nitrogen protection, 70 ℃ polymerization reaction for 24 hours, dialyzed after the reaction, and then freeze-dried at -50 ℃ to obtain the epoxy-containing phosphorylcholine polymer.

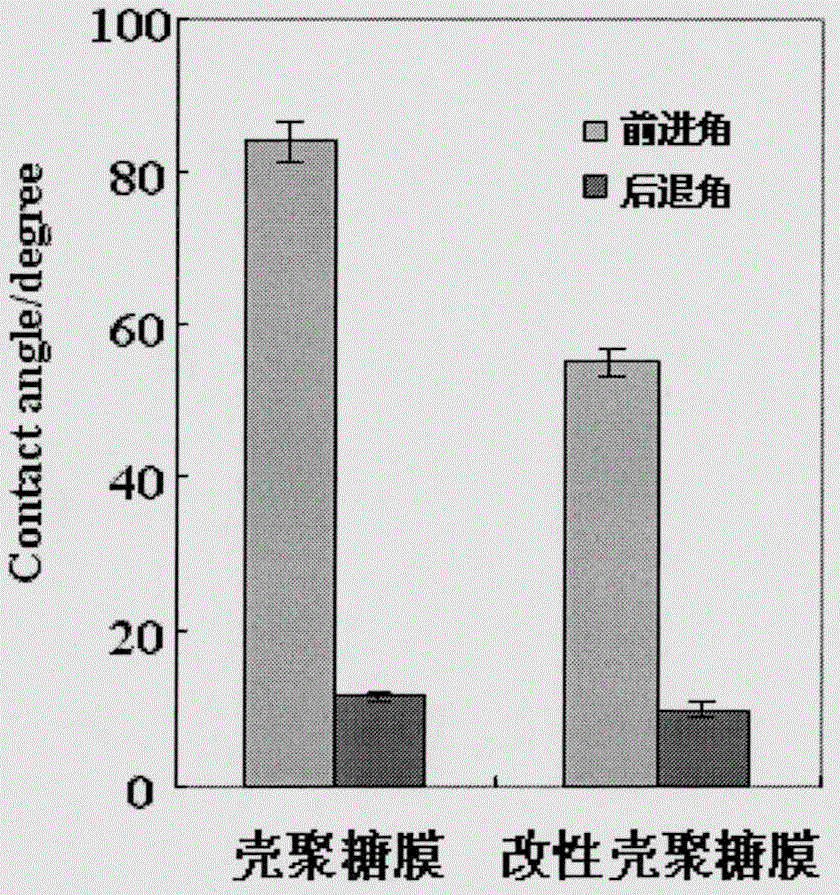

[0034] The epoxy-containing phosphorylcholine polymer prepared in this example was prepared into 2 mL, 2 mg / mL methanol solution, and then 1 g of dopamine was added and mixed evenly. Then the above-mentioned mixed solution containing epoxy-containing phosphorylcholine polymer and dopamine is drop-coated on the chitosan surface. Among them, the mixed solution of phosphorylcholine polymer containing epoxy and dopamine is dripped and dried, and then placed in a pH=8.5 Tris-HCl aqueous solution at 45°C for 12 hours, so that the amino group in dopamine and the amino group on the surface of chitosan film are combine...

Embodiment 3

[0036] Weigh 19mmol 2-methacryloyloxyethylphosphorylcholine and 1mmol glycidyl methacrylate, use 0.1mmol azobisisobutyronitrile as the initiator, methanol and tetrahydrofuran as the solvent, under nitrogen protection, 70 ℃ polymerization reaction for 24 hours, dialyzed after the reaction, and then freeze-dried at -50 ℃ to obtain the epoxy-containing phosphorylcholine polymer.

[0037] The epoxy-containing phosphorylcholine polymer prepared in this example was prepared into 2 mL, 5 mg / mL methanol solution, and then 0.8 g of dopamine was added and mixed evenly. Then the above-mentioned mixed solution containing epoxy-containing phosphorylcholine polymer and dopamine is drop-coated on the chitosan surface. Among them, the mixed solution of phosphorylcholine polymer and dopamine containing epoxy is dripped and dried, and then placed in pH=8.5 Tris-HCl aqueous solution at 95 ° C for 2 hours, so that the amino group in dopamine and the amino group on the surface of chitosan film are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com